Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wet Pour Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

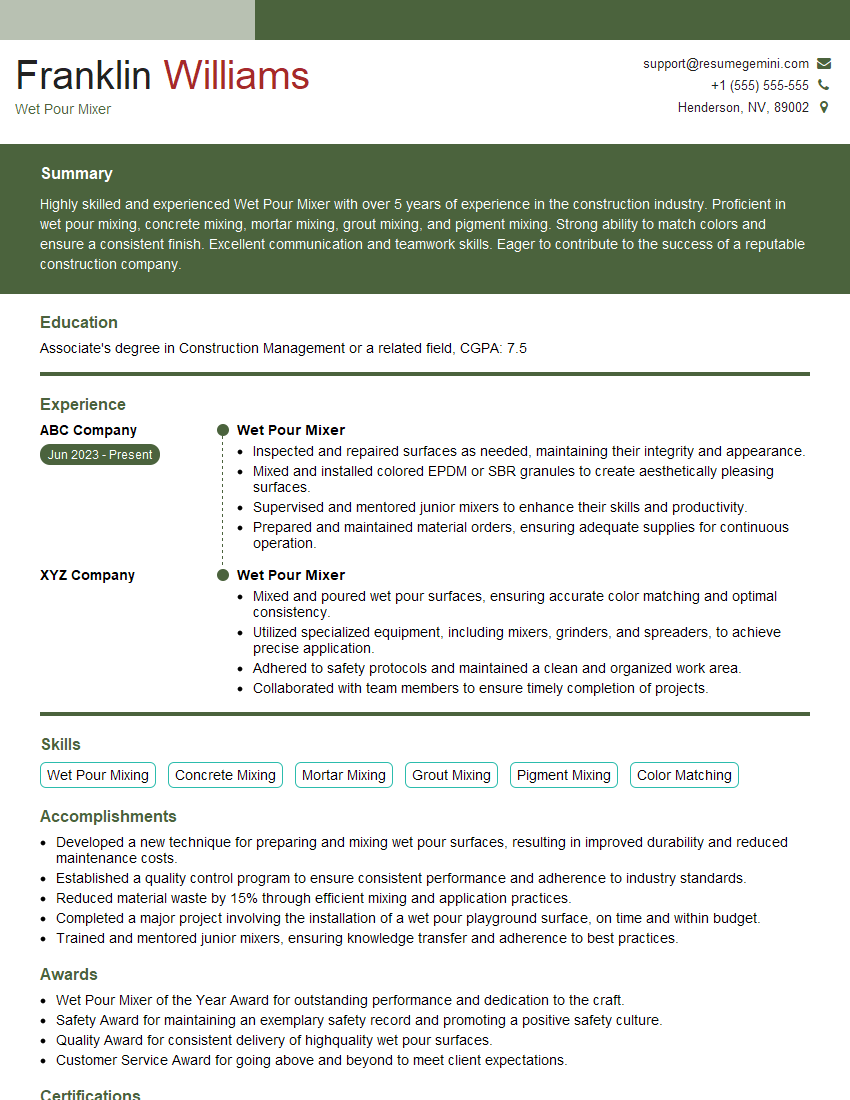

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Pour Mixer

1. What is the process of wet pour rubber surfacing?

Wet pour rubber surfacing is a playground surfacing that is made from recycled rubber granules. The granules are mixed with a liquid binder and then poured onto a prepared surface. The surface is then leveled and compacted to create a smooth, durable surface.

- The first step is to prepare the surface by removing any existing materials and leveling the ground.

- The next step is to mix the rubber granules with the liquid binder. The binder is typically made from polyurethane or epoxy resin.

- The mixed rubber granules are then poured onto the prepared surface and leveled using a screed or trowel.

- The surface is then compacted using a roller to create a smooth, durable surface.

- The final step is to allow the surface to cure for 24-48 hours before it can be used.

2. What are the different types of wet pour rubber surfaces?

Permeable Surfaces

- Permeable surfaces allow water to drain through them, making them ideal for areas that are prone to flooding.

- Permeable surfaces are made with a special binder that allows water to pass through while still holding the rubber granules together.

Non-Permeable Surfaces

- Non-permeable surfaces do not allow water to drain through them, making them ideal for areas that need to be kept dry.

- Non-permeable surfaces are made with a binder that does not allow water to pass through.

3. How do you choose the right type of wet pour rubber surface for a particular application?

The type of wet pour rubber surface that is right for a particular application will depend on a number of factors, including:

- The intended use of the surface

- The amount of traffic the surface will receive

- The climate in which the surface will be installed

- The budget for the project

4. How do you install a wet pour rubber surface?

The installation of a wet pour rubber surface typically involves the following steps:

- Preparing the surface

- Mixing the rubber granules with the liquid binder

- Pouring the mixed rubber granules onto the prepared surface

- Leveling the surface

- Compacting the surface

- Allowing the surface to cure

5. How do you maintain a wet pour rubber surface?

To maintain a wet pour rubber surface, it is important to:

- Sweep or vacuum the surface regularly to remove dirt and debris.

- Wash the surface with a mild detergent and water as needed.

- Inspect the surface regularly for any signs of damage and repair any damage as needed.

6. What are the advantages of using wet pour rubber surfaces?

- Wet pour rubber surfaces are durable and can withstand heavy traffic.

- Wet pour rubber surfaces are slip-resistant, making them safe for use in areas where people are likely to fall.

- Wet pour rubber surfaces are porous, which allows water to drain through them and helps to prevent puddles from forming.

- Wet pour rubber surfaces are UV-resistant, which means that they will not fade or discolor over time.

- Wet pour rubber surfaces are easy to maintain and can be cleaned with a mild detergent and water.

7. What are the disadvantages of using wet pour rubber surfaces?

- Wet pour rubber surfaces can be expensive to install.

- Wet pour rubber surfaces can be difficult to repair if they are damaged.

- Wet pour rubber surfaces can become hot in the sun.

- Wet pour rubber surfaces can emit a strong odor when they are first installed.

8. What are some of the common problems that can occur with wet pour rubber surfaces?

- Cracking

- Fading

- Bubbling

- Rippling

- Discoloration

9. What is the best way to repair a wet pour rubber surface?

The best way to repair a wet pour rubber surface will depend on the type of damage that has occurred.

- For small cracks, you can use a rubber sealant to fill the crack.

- For larger cracks, you may need to cut out the damaged area and replace it with a new piece of rubber.

- For faded areas, you can use a rubber paint to restore the color.

- For bubbling or rippling, you can use a heat gun to smooth out the surface.

- For discoloration, you can use a mild bleach solution to clean the surface.

10. How long will a wet pour rubber surface last?

The lifespan of a wet pour rubber surface will depend on a number of factors, including the quality of the installation, the amount of traffic the surface receives, and the climate in which the surface is installed.

- With proper maintenance, a wet pour rubber surface can last for 10-15 years.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Pour Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Pour Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

- Manage and operate wet pour machines: Ensuring proper functioning and upkeep of wet pour mixing equipment, including calibration, adjustment, and maintenance.

- Mix and prepare wet pour materials: Accurately measuring and mixing raw materials, including aggregates, resins, and pigments, according to established formulas.

- Install and maintain play surfaces: Installing, repairing, and maintaining wet pour surfaces on playgrounds, sports fields, and other areas.

- Monitor production process: Overseeing the mixing process, monitoring product quality, and making necessary adjustments to ensure adherence to specifications.

- Maintain a clean and safe work environment: Cleaning and organizing the work area, ensuring the proper disposal of materials, and adhering to safety protocols.

- Operate forklifts or other lifting equipment: Safely operating forklifts or other equipment to move materials and equipment on the job site.

- Work in various weather conditions: Performing tasks in both indoor and outdoor environments, often exposed to inclement weather conditions.

- Follow safety guidelines and procedures: Adhering to all safety regulations and protocols, including wearing appropriate protective gear and operating equipment safely.

Interview Tips

To ace your interview for the Wet Pour Mixer position, consider these preparation tips:

- Research the company and the industry: Familiarize yourself with the company’s history, products or services, and the latest trends in the wet pour industry.

- Practice your answers to common interview questions: Prepare responses to questions about your experience, skills, and why you’re interested in the position.

- Emphasize your relevant skills and experience: Highlight your proficiency in operating wet pour machines, mixing materials, and installing and maintaining play surfaces.

- Quantify your accomplishments: Use specific examples and metrics to demonstrate your contributions in previous roles.

- Prepare questions for the interviewer: Asking thoughtful questions shows your engagement and interest in the position.

- Dress professionally and arrive on time: First impressions matter, so dress appropriately and punctuality demonstrates your respect for the interviewer’s time.

- Be enthusiastic and positive: Convey your passion for the industry and your eagerness to contribute to the company’s success.

- Follow up after the interview: Thank the interviewer for their time and reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wet Pour Mixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.