Are you gearing up for a career in Computerized Table Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Computerized Table Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

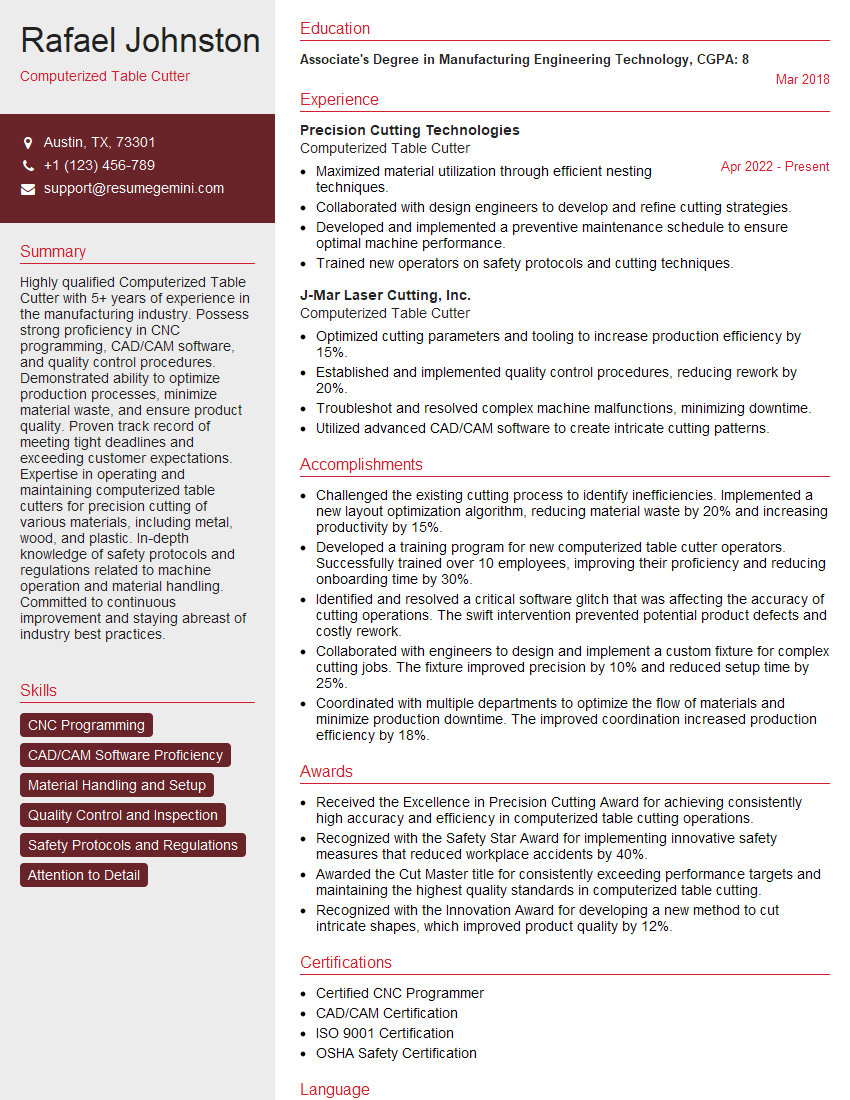

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computerized Table Cutter

1. What are the different types of computerized table cutters?

There are two main types of computerized table cutters:

- CNC (Computer Numerical Control) cutters: These cutters are controlled by a computer program that uses numerical data to guide the cutting head. CNC cutters are typically used for high-volume, precision cutting of materials such as wood, plastic, and metal.

- Laser cutters: These cutters use a laser beam to cut materials. Laser cutters are typically used for cutting intricate designs in thin materials such as paper, fabric, and wood.

2. What are the advantages of using a computerized table cutter?

- Increased accuracy: Computerized table cutters are much more accurate than manual cutters, resulting in higher quality cuts.

- Increased speed: Computerized table cutters can cut materials much faster than manual cutters, increasing productivity.

- Reduced labor costs: Computerized table cutters can reduce the need for manual labor, saving businesses money on labor costs.

- Increased versatility: Computerized table cutters can be used to cut a wide variety of materials, making them a versatile tool for a variety of applications.

3. What are the different factors to consider when choosing a computerized table cutter?

When choosing a computerized table cutter, there are a number of factors to consider, including:

- The type of material to be cut: Different materials require different types of cutters. For example, a CNC cutter is best suited for cutting hard materials such as wood and metal, while a laser cutter is best suited for cutting thin materials such as paper and fabric.

- The size of the material to be cut: The size of the material will determine the size of the cutter needed.

- The desired cutting accuracy: The desired cutting accuracy will determine the type of cutter and cutting head required.

- The budget: The budget will determine the type and features of the cutter that can be purchased.

4. What are the safety precautions that must be taken when operating a computerized table cutter?

- Wear proper safety gear: Wear eye protection, earplugs, and gloves when operating a computerized table cutter.

- Keep the work area clean: A clean work area will help to prevent accidents.

- Be aware of the cutter’s location: Always be aware of the location of the cutter’s blade and keep your hands away from it.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for operating the computerized table cutter.

5. What are some of the common problems that can occur when operating a computerized table cutter?

- The cutter is not cutting accurately: This could be due to a number of factors, such as a dull blade, a misaligned cutter head, or a problem with the computer program.

- The cutter is making excessive noise: This could be due to a number of factors, such as a loose belt or a damaged bearing.

- The cutter is not cutting through the material: This could be due to a number of factors, such as a dull blade or a lack of power.

- The cutter is overheating: This could be due to a number of factors, such as a lack of lubrication or a problem with the motor.

6. What are some of the maintenance tasks that must be performed on a computerized table cutter?

- Clean the cutter: Clean the cutter regularly to remove dust and debris.

- Lubricate the cutter: Lubricate the cutter regularly to prevent wear and tear.

- Inspect the cutter: Inspect the cutter regularly for any signs of damage.

- Calibrate the cutter: Calibrate the cutter regularly to ensure that it is cutting accurately.

7. What are some of the skills required to be a successful computerized table cutter?

- Computer literacy: Computer literacy is essential for operating a computerized table cutter.

- Attention to detail: Attention to detail is important for ensuring that the cutter is cutting accurately.

- Mechanical aptitude: Mechanical aptitude is important for maintaining and repairing the cutter.

- Safety consciousness: Safety consciousness is important for operating the cutter safely.

8. What are some of the applications for computerized table cutters?

- Signage: Computerized table cutters can be used to cut signage out of a variety of materials, such as wood, plastic, and metal.

- Displays: Computerized table cutters can be used to cut displays out of a variety of materials, such as cardboard, foam board, and fabric.

- Prototype parts: Computerized table cutters can be used to cut prototype parts out of a variety of materials, such as wood, plastic, and metal.

- Custom products: Computerized table cutters can be used to create custom products, such as gifts, home décor, and jewelry.

9. What are some of the trends in the computerized table cutter industry?

- Increased automation: Computerized table cutters are becoming increasingly automated, with features such as automatic tool changers and automatic material handling systems.

- Improved accuracy: Computerized table cutters are becoming increasingly accurate, with features such as high-resolution encoders and closed-loop feedback systems.

- Increased speed: Computerized table cutters are becoming increasingly faster, with features such as high-speed motors and linear drive systems.

- Increased versatility: Computerized table cutters are becoming increasingly versatile, with features such as the ability to cut a wide variety of materials and the ability to perform a variety of different cutting operations.

10. What are some of the challenges facing the computerized table cutter industry?

- The increasing cost of materials: The increasing cost of materials is a major challenge facing the computerized table cutter industry.

- The rising cost of labor: The rising cost of labor is another major challenge facing the computerized table cutter industry.

- The competition from overseas manufacturers: The competition from overseas manufacturers is a major challenge facing the computerized table cutter industry.

- The need for new and innovative products: The need for new and innovative products is a major challenge facing the computerized table cutter industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computerized Table Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computerized Table Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Computerized Table Cutter, your primary responsibilities include operating and maintaining computerized table cutting machines to produce precision cuts on a variety of materials.

1. Operation of Computerized Table Cutter

You will be responsible for setting up, operating, and maintaining the computerized table cutter to achieve optimal cutting accuracy and efficiency.

- Operate computerized table cutting machines to cut materials such as fabric, leather, rubber, foam, and composite materials.

- Load materials onto the cutting table and secure them properly.

- Program the cutting machine using computer-aided design (CAD) software.

- Monitor the cutting process and make adjustments as needed.

- Ensure that cuts are made precisely and meet specifications.

2. Maintenance and Troubleshooting of Computerized Table Cutter

You will be responsible for performing regular maintenance and troubleshooting of the computerized table cutter to ensure its proper functioning.

- Conduct regular maintenance checks on the computerized table cutter.

- Identify and troubleshoot any mechanical or electrical issues.

- Perform routine cleaning and lubrication of the machine.

- Calibrate the cutting machine to ensure accuracy.

- Consult with technical support or repair professionals when necessary.

3. Material Handling and Quality Control

You will need to handle materials properly to prevent damage and ensure quality.

- Handle materials with care to prevent damage.

- Inspect cut materials for accuracy and quality.

- Identify and resolve any defects or errors in the cutting process.

- Maintain a clean and organized work area.

4. Safety and Compliance

You are responsible for adhering to safety protocols and ensuring compliance with relevant regulations.

- Follow all safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Maintain a safe and orderly work environment.

- Comply with all applicable regulations and industry standards.

Interview Tips

To ace the interview for a Computerized Table Cutter position, it’s important to:

1. Research the Company and Position

Familiarize yourself with the company’s background, products/services, and culture. Research the specific responsibilities of the Computerized Table Cutter role and the company’s expectations.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating computerized table cutting machines, including your experience with different types of materials and CAD software. Showcase your ability to maintain and troubleshoot the equipment, ensuring optimal performance.

3. Demonstrate Attention to Detail

Stress your meticulous approach to material handling and quality control. Explain your ability to identify and correct errors, ensuring the precision and accuracy of the cuts. Emphasize your adherence to safety protocols and compliance with industry standards.

4. Show Enthusiasm and Willingness to Learn

Convey your passion for operating computerized table cutting machines and your eagerness to enhance your skills. Express your interest in learning new techniques and technologies to improve efficiency and productivity.

5. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role?,” and “What are your strengths and weaknesses?” Practice your answers to highlight your relevant qualifications and demonstrate your confidence.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Computerized Table Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.