Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Computerized Machine Fabric Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

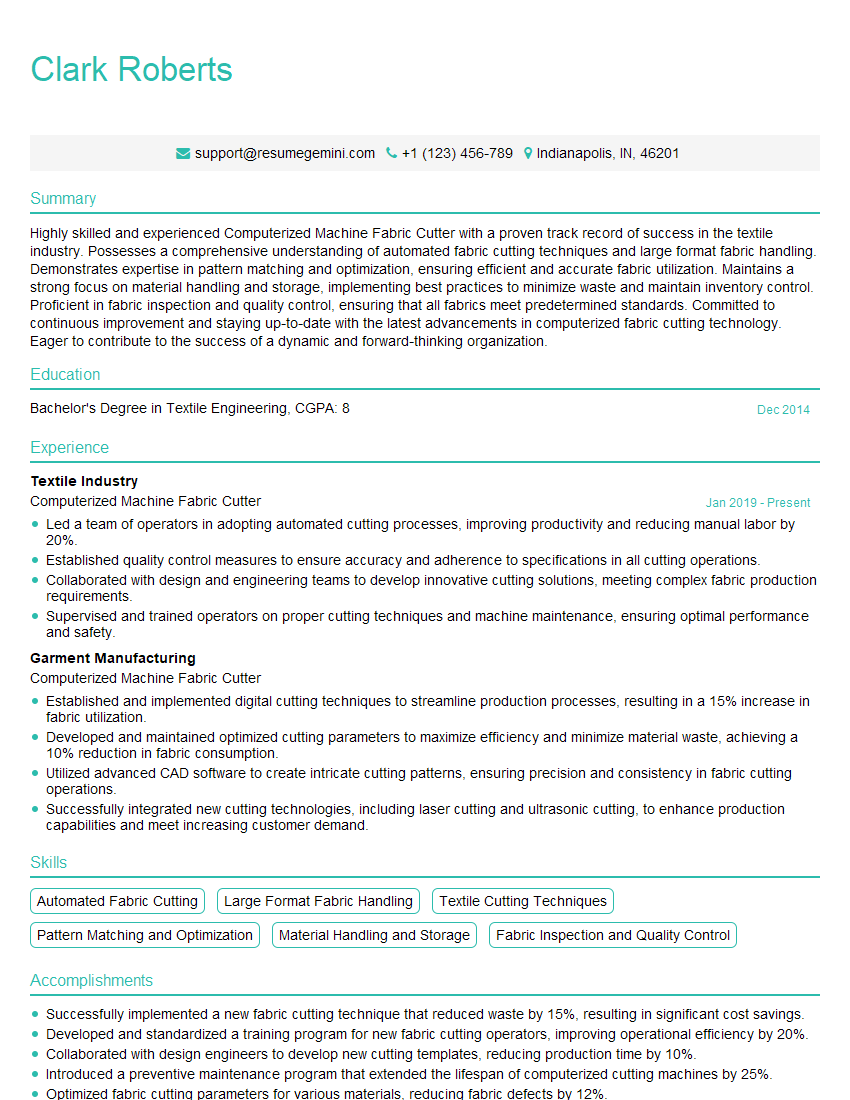

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computerized Machine Fabric Cutter

1. What is the process of using a computerized machine fabric cutter?

The process of using a computerized machine fabric cutter involves several steps, including:

- Preparing the fabric: The fabric to be cut is placed on the cutting table and secured using clamps or vacuum suction.

- Creating the cutting pattern: The desired cutting pattern is created using a computer-aided design (CAD) software and loaded into the machine’s control system.

- Positioning the fabric: The fabric is positioned on the cutting table according to the pattern’s specifications.

- Cutting: The machine’s blade moves along the programmed path, cutting the fabric according to the pattern.

- Unloading: The cut fabric pieces are unloaded from the cutting table and inspected for accuracy.

2. What safety precautions should be taken when operating a computerized machine fabric cutter?

Personal safety gear

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

- Keep long hair and loose clothing tied back to prevent entanglement.

Machine safety

- Ensure that the machine is properly grounded to prevent electrical hazards.

- Keep the cutting area clean and free of debris.

- Never operate the machine without the blade guard in place.

- Follow the manufacturer’s instructions for proper maintenance and operation.

3. How do you maintain a computerized machine fabric cutter?

- Regular cleaning: Clean the cutting table, blade, and other components regularly to remove fabric residue and prevent wear and tear.

- Blade lubrication: Lubricate the blade according to the manufacturer’s recommendations to ensure smooth cutting and prolong its lifespan.

- Software updates: Update the machine’s control software regularly to ensure optimal performance and compatibility with new pattern designs.

- Routine inspections: Conduct regular inspections of the machine’s electrical components, belts, and other parts to identify and address any potential issues early on.

- Preventive maintenance: Schedule regular preventive maintenance with a qualified technician to ensure the machine’s overall reliability and longevity.

4. What types of fabrics can be cut using a computerized machine fabric cutter?

- Natural fibers: Cotton, linen, silk, wool

- Synthetic fibers: Polyester, nylon, spandex, rayon

- Woven and knitted fabrics

- Leather and faux leather

- Multiple layers of fabric

5. What are the advantages of using a computerized machine fabric cutter?

- Precision and accuracy: Computerized cutters follow precise patterns, ensuring accurate and consistent cutting.

- Efficiency: The automated cutting process significantly reduces cutting time compared to manual methods.

- Material savings: The optimized cutting patterns minimize fabric waste and maximize material usage.

- Versatility: Computerized cutters can handle a wide range of fabrics and thicknesses.

- Ease of use: Machines are designed to be user-friendly with intuitive software and controls.

6. What are the challenges of operating a computerized machine fabric cutter?

- Cost: Computerized fabric cutters are expensive to purchase and maintain.

- Technical expertise: Operating the machine and understanding the software requires technical knowledge.

- fabric limitations: Not all fabrics are suitable for cutting with a computerized machine, and certain materials may require special techniques.

- Maintenance and downtime: Regular maintenance and occasional repairs are necessary to ensure optimal performance.

- Safety concerns: As with any machinery, it is important to prioritize safety and follow proper operating procedures.

7. How do you troubleshoot common problems with a computerized machine fabric cutter?

- Blade issues: Replace dull or damaged blades, adjust blade tension, or lubricate moving parts.

- Software errors: Restart the software, check for updates, or contact technical support.

- Mechanical problems: Inspect belts, gears, and other moving parts for damage or misalignment.

- Fabric feeding issues: Ensure the fabric is properly loaded and adjusted for the correct tension.

- Safety features: Check if safety sensors are functioning correctly and troubleshoot any issues related to blade guards or emergency stops.

8. What is the role of a computerized machine fabric cutter in the textile industry?

- Automated fabric cutting: Computerized cutters handle the cutting of fabric, eliminating the need for manual labor and increasing efficiency.

- Pattern optimization: The software optimizes cutting patterns to minimize waste and maximize fabric utilization.

- Sample making: Fast and accurate cutting enables efficient sample making for product development and quality control.

- Mass production: Computerized cutters support large-scale fabric cutting for garment manufacturing and other textile applications.

- Customization: Advancements in digital printing and cutting technologies allow for personalized and customized fabric cutting.

9. How do you stay up-to-date with the latest advancements in computerized machine fabric cutting technology?

- Industry events: Attend trade shows and conferences to learn about new developments.

- Technical publications: Subscribe to industry magazines and online resources for the latest news and articles.

- Online forums: Participate in online discussions and knowledge-sharing platforms.

- Manufacturer updates: Stay informed about software and hardware updates from the equipment manufacturer.

- Training opportunities: Take advantage of training programs offered by manufacturers or industry organizations.

10. What are your career goals in the field of computerized machine fabric cutting?

My career goals in the field of computerized machine fabric cutting are to:

- Master the technical aspects: Thoroughly understand the machine’s operation, software, and maintenance procedures.

- Improve efficiency and accuracy: Continuously seek ways to optimize cutting processes, reduce waste, and ensure high-quality results.

- Contribute to innovation: Explore new techniques and applications for computerized fabric cutting, supporting advancements in the industry.

- Advance in the field: Stay abreast of technological developments and take on leadership roles within the field.

- Utilize my skills: Apply my knowledge and expertise to support businesses in achieving their fabric cutting objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computerized Machine Fabric Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computerized Machine Fabric Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computerized Machine Fabric Cutters are responsible for operating computerized machines to cut fabric for clothing, furniture, and other products. They work closely with fabric designers and production managers to ensure that the fabric is cut according to specifications.

1. Machine Operation

Computerized Machine Fabric Cutters are responsible for setting up and operating computerized cutting machines. They must be able to understand and follow instructions, and they must be able to troubleshoot problems that may arise.

- Set up and calibrate computerized cutting machines

- Load fabric onto the cutting table

- Operate the cutting machine to cut the fabric according to the programmed pattern

2. Fabric Inspection

Computerized Machine Fabric Cutters are responsible for inspecting the cut fabric to ensure that it meets quality standards. They must be able to identify defects, and they must be able to measure the fabric to ensure that it is the correct size.

- Inspect the cut fabric for defects

- Measure the fabric to ensure that it is the correct size

- Report any defects or errors to the supervisor

3. Material Handling

Computerized Machine Fabric Cutters are responsible for handling large rolls and bolts of fabric. They must be able to lift and move heavy objects, often for hours on end.

- Load and unload fabric rolls from the cutting table

- Move cut fabric to storage or shipping areas

- Dispose of fabric scraps

4. Safety

Computerized Machine Fabric Cutters work with sharp blades and other dangerous equipment. They must be familiar with safety procedures, and they must be able to work safely and efficiently.

- Follow all safety procedures

- Wear appropriate safety gear

- Keep the work area clean and organized

Interview Tips

Here are a few tips to help you ace your interview for a Computerized Machine Fabric Cutter position:

1. Research the company and the position

Before you go on your interview, it’s important to do your research on the company and the position you’re applying for. This will help you to understand the company’s culture and values, and it will also help you to prepare for the questions that you’re likely to be asked.

- Visit the company’s website

- Read articles about the company in trade publications

- Talk to people who work for the company

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions so that you can deliver them confidently and clearly.

- Write out your answers to common interview questions

- Practice your answers aloud

- Get feedback from a friend or family member

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt. You should also make sure that your clothes are clean and pressed.

- Choose a suit or dress pants and a button-down shirt in a neutral color

- Make sure your clothes are clean and pressed

- Avoid wearing too much jewelry or perfume

4. Be on time

Punctuality is important for any job interview, but it’s especially important for a job that requires you to be on time for work every day. Make sure to arrive at your interview on time, or even a few minutes early.

- Plan your route to the interview in advance

- Leave early to allow for traffic and parking

- If you’re running late, call the interviewer to let them know

5. Be confident

Confidence is key in any job interview. Make sure to maintain eye contact with the interviewer, and speak clearly and confidently. Don’t be afraid to ask questions, and be prepared to talk about your experience and skills.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Be prepared to talk about your experience and skills

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Computerized Machine Fabric Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.