Are you gearing up for a career in Hand Tire Trimmer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hand Tire Trimmer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

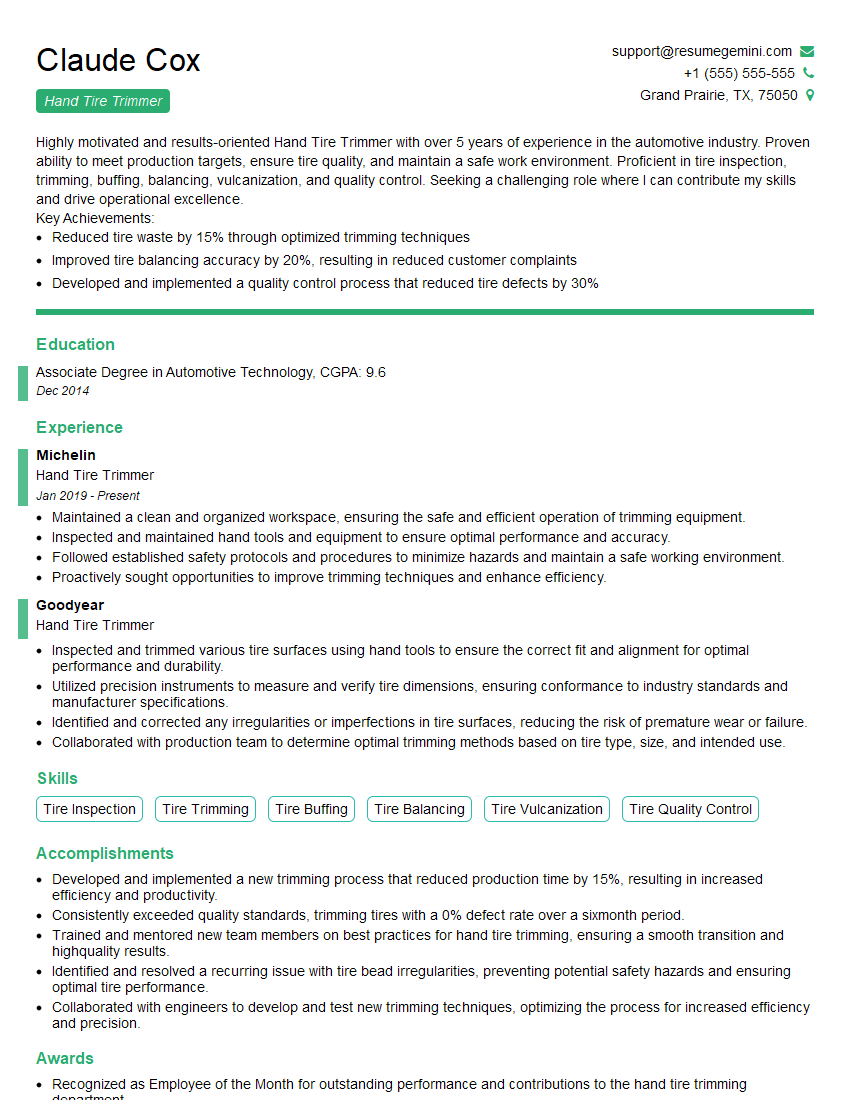

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Tire Trimmer

1. How do you use a trimming machine to trim the excess material from a tire?

To trim excess material from a tire using a trimming machine, I follow these steps:

- Position the tire correctly on the trimming machine, ensuring it is centered and securely held.

- Adjust the blade depth and speed according to the tire size and material.

- Activate the machine and slowly guide the blade around the circumference of the tire.

- Maintain a steady and consistent pressure to ensure an even trim.

- Inspect the trimmed tire for any imperfections or missed areas, and make necessary adjustments.

2. What are the different types of trimming blades used in tire trimming?

There are several types of trimming blades used in tire trimming:

Types of Trimming Blades:

- Carbide Tipped Blades: Durable and long-lasting, suitable for trimming a variety of tire materials, including rubber and steel.

- High-Speed Steel Blades: Less durable than carbide blades but provide a finer finish, ideal for precision trimming.

- “V” Grooved Blades: Designed to create a specific groove pattern on the tire surface, improving traction and performance.

- Specialty Blades: Custom-designed blades for specific trimming applications, such as trimming tires for racing or off-road use.

3. How do you maintain and sharpen trimming blades to ensure optimal performance?

To maintain and sharpen trimming blades for optimal performance:

- Regular Inspection: Regularly inspect blades for wear, damage, or dullness.

- Blade Cleaning: Clean blades thoroughly after each use to remove debris and prevent corrosion.

- Sharpening: Use a specialized blade sharpener to sharpen blades to the desired sharpness.

- Proper Storage: Store blades properly to prevent damage and maintain sharpness.

- Regular Maintenance: Follow the manufacturer’s maintenance recommendations to ensure proper alignment and blade performance.

4. What safety precautions should be observed when operating a tire trimming machine?

To ensure safety when operating a tire trimming machine:

- Wear appropriate safety gear: Safety glasses, gloves, and hearing protection.

- Secure the tire properly: Ensure the tire is securely mounted on the machine to prevent accidents.

- Maintain a clean workspace: Keep the work area free of debris to reduce tripping hazards.

- Avoid loose clothing or jewelry: Secure loose clothing or jewelry to prevent entanglement.

- Follow operating instructions carefully: Familiarize yourself with the machine’s operation and follow all instructions.

5. Describe the different quality control checks performed on trimmed tires to ensure precision and accuracy.

To ensure precision and accuracy, trimmed tires undergo various quality control checks:

- Visual Inspection: Tires are visually inspected for any irregularities, such as uneven trimming or missed areas.

- Dimensional Measurement: Tires are measured to ensure they meet the specified dimensions and tolerances.

- Surface Finish Inspection: The surface of the trimmed tire is inspected for any imperfections or defects.

- Performance Testing: In some cases, tires may be subjected to performance tests, such as rolling resistance or traction tests.

- Documentation: Quality control checks are documented to ensure traceability and accountability.

6. How do you troubleshoot common issues that may arise during the tire trimming process?

To troubleshoot common tire trimming issues:

- Uneven Trimming: Adjust the blade depth or alignment, or check for loose or damaged components.

- Missed Areas: Ensure the tire is properly positioned and that the blade is making contact with the entire surface.

- Poor Surface Finish: Replace dull or damaged blades, or adjust the blade speed and pressure.

- Machine Malfunction: Check for any electrical or mechanical issues, consult the machine’s manual, or contact the manufacturer.

- Tire Damage: If the tire is damaged during trimming, assess the extent of the damage and consult with a supervisor or quality control personnel.

7. How do you minimize waste and optimize material usage during tire trimming?

To minimize waste and optimize material usage:

- Accurate Trimming: Ensure precise trimming to avoid excessive material removal.

- Reuse Excess Material: Collect and reuse excess material for other applications, such as in-house recycling or external sale.

- Optimize Blade Selection: Use the appropriate blade type and size to minimize unnecessary material removal.

- Proper Blade Maintenance: Regularly inspect and maintain blades to prevent dullness and ensure efficient cutting.

- Training and Monitoring: Train operators on proper trimming techniques and monitor production to identify areas for improvement.

8. Describe the role of automation in modern tire trimming processes.

Automation plays a significant role in modern tire trimming processes:

- Increased Efficiency: Automated machines can perform trimming tasks faster and with greater precision than manual labor.

- Reduced Labor Costs: Automation reduces the need for a large workforce, resulting in lower labor costs.

- Improved Quality: Automated machines can consistently produce high-quality trimmed tires due to precise control of blade depth and speed.

- Increased Production Capacity: Automation enables continuous operation, allowing for higher production capacity and shorter lead times.

- Enhanced Safety: Automated machines eliminate the risks associated with manual trimming, such as repetitive motions and potential injuries.

9. How do you stay updated with the latest advancements and best practices in tire trimming technology?

To stay updated with advancements and best practices:

- Attend Industry Events: Participate in trade shows and conferences to learn about new technologies and connect with experts.

- Research and Development: Stay informed through industry publications, technical papers, and online resources.

- Collaboration with Suppliers: Engage with suppliers and manufacturers to gain insights into the latest technologies and industry trends.

- Continuous Learning: Participate in training programs and workshops to enhance skills and knowledge.

- Benchmarking: Study and compare practices with other facilities to identify areas for improvement and innovation.

10. How do you prioritize and manage multiple projects with varying timelines and priorities?

To prioritize and manage multiple projects:

- Project Planning: Define clear project goals, timelines, and resource allocation.

- Prioritization Techniques: Use prioritization methods such as the Eisenhower Matrix or MoSCoW analysis to determine the importance and urgency of projects.

- Communication and Collaboration: Communicate project plans and deadlines to stakeholders to ensure alignment and support.

- Resource Management: Allocate resources effectively to ensure timely completion of critical projects.

- Regular Monitoring and Adjustment: Track project progress and make necessary adjustments to ensure adherence to timelines and priorities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Tire Trimmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Tire Trimmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hand Tire Trimmer is responsible for a variety of tasks related to the production and maintenance of tires. Their primary duty is to inspect, cut, and trim raw tire materials, ensuring that they meet the required specifications and quality standards.

1. Tire Inspection and Trimming

Examine raw tire materials, including tread rubber, sidewalls, and bead wires, for defects, imperfections, and deviations from the specified dimensions.

- Use a range of tools and equipment, such as calipers, gauges, and cutters, to precisely trim and shape tire components.

- Ensure that the trimmed materials comply with established quality standards and meet the product specifications.

2. Material Handling and Storage

Handle and move raw tire materials and finished products safely and efficiently.

- Unload and load materials using forklifts, cranes, and other equipment.

- Maintain an organized and clean work area, adhering to safety regulations and best practices.

3. Equipment Operation and Maintenance

Operate and maintain a variety of equipment used in the tire trimming process.

- Set up, calibrate, and operate cutting machines, grinders, and other tools.

- Perform routine maintenance, such as cleaning, lubricating, and inspecting equipment to ensure optimal performance.

4. Quality Control and Documentation

Monitor and maintain the quality of finished products.

- Inspect and document the results of tire trimming and shaping operations.

- Record and report any deviations from the established standards and specifications.

Interview Tips

Preparing for an interview for a Hand Tire Trimmer position is essential to make a positive impression and showcase your skills and qualifications.

1. Research the Company and Role

Thoroughly research the company and the specific Hand Tire Trimmer role you are applying for. This will provide you with insights into the company’s culture, values, and the responsibilities associated with the position.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and articles to stay abreast of current trends and best practices in tire manufacturing.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize your skills and experience that are relevant to the Hand Tire Trimmer role. Focus on your ability to inspect, trim, and shape tire materials precisely, as well as your experience in handling and operating equipment.

- Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate the impact of your work.

- If you have experience in a related field, such as manufacturing or quality control, highlight the transferable skills you have gained.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers aloud. This will help you articulate your thoughts clearly and confidently during the interview.

- Some common interview questions for a Hand Tire Trimmer include:

- “Tell me about your experience in inspecting and trimming tire materials.”

- “Describe your knowledge of tire manufacturing processes.”

- “How do you ensure that finished products meet quality standards?”

4. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Maintain a positive and enthusiastic attitude throughout the interview. This will demonstrate your interest in the role and your commitment to making a positive contribution to the company.

- Be respectful of the interviewer’s time and answer questions honestly and succinctly.

- Ask thoughtful questions at the end of the interview to show your engagement and interest in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hand Tire Trimmer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hand Tire Trimmer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.