Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sample Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

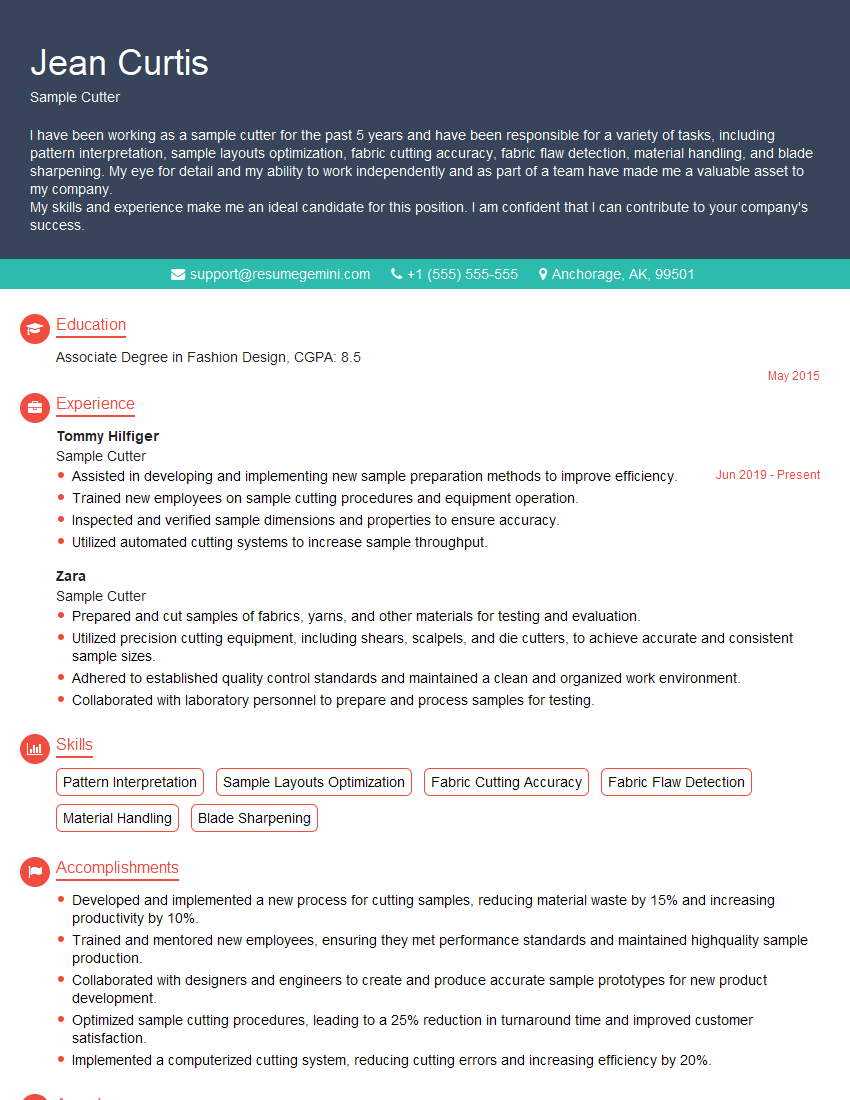

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sample Cutter

1. Describe the different types of cutting tools used in sample cutting and their applications.

In sample cutting, we utilize various cutting tools for specific purposes. Here are some common types of cutting tools and their applications:

- Band knife: A continuous, flexible blade used for cutting intricate curves and patterns in fabrics.

- Straight knife: A sharp, straight blade for cutting straight lines and edges.

- Rotary cutter: A circular blade mounted on a handle, used for cutting fabrics in large quantities or for circular shapes.

- Laser cutter: A high-powered laser used for precise and intricate cutting of fabrics.

- Water jet cutter: A machine that utilizes a high-pressure water jet to cut through various materials, including fabrics.

2. Explain the importance of grain line matching in sample cutting.

Accuracy and Fabric Structure

- Grain line matching ensures that fabrics are cut with the grain, maintaining the fabric’s structural integrity.

- Cutting against the grain can weaken the fabric and cause distortion and shrinkage during garment construction.

Dimensional Stability

- Grain line matching helps maintain the fabric’s dimensional stability, preventing stretching or shrinkage in certain directions.

- This is crucial for achieving the desired fit and drape of garments.

3. Describe the steps involved in preparing fabrics for cutting.

- Inspecting the fabric: Checking for any defects or flaws that may affect cutting accuracy.

- Pre-shrinking the fabric: Washing and drying the fabric to remove any shrinkage before cutting, ensuring accurate sizing.

- Folding and laying out the fabric: Aligning and smoothing the fabric layers to ensure accurate cutting.

- Marking the cutting lines: Using chalk, pens, or tracing paper to transfer the pattern markings onto the fabric.

4. What are the different methods of pattern marking used in sample cutting?

- Notching: Small cuts made into the seam allowance to indicate specific points for matching during sewing.

- Clipping: Small cuts made into corners or curves to reduce bulk and allow for ease of sewing.

- Dart marking: Lines or markings indicating where darts should be sewn.

- Pleat marking: Lines or markings indicating where pleats should be folded and sewn.

5. Describe the techniques for cutting bias strips.

- Determining the bias direction: Identifying the 45-degree angle to the selvage.

- Folding the fabric: Folding the fabric diagonally, matching the selvages to create a triangle.

- Trimming the selvages: Removing the selvages to create a clean edge.

- Cutting the bias strips: Using a sharp rotary cutter or scissors to cut strips parallel to the folded edge.

6. Explain the safety precautions that must be taken while operating cutting machines.

- Wear appropriate personal protective equipment (PPE): Eye protection, gloves, and a dust mask.

- Keep the work area clean and organized: Remove fabric scraps and debris to prevent tripping hazards.

- Inspect machines regularly: Check for any loose wires, damaged blades, or other potential hazards.

- Follow proper operating procedures: Familiarize yourself with the machine’s controls and instructions.

- Never reach across or touch a running blade: Always use a cutting tool to manipulate fabrics.

7. What are the common mistakes to avoid in sample cutting?

- Cutting against the grain: This can weaken the fabric and cause distortion.

- Inaccurate pattern layout: Misaligned or incorrectly placed patterns can result in cutting errors.

- Incorrect marking: Improper or unclear markings can lead to cutting mistakes.

- Cutting too close to the pattern edge: This can compromise the seam allowance.

- Not taking into account seam allowances: Neglecting to add seam allowances can result in garments that are too small.

8. How do you ensure the accuracy and consistency of your cutting?

- Utilizing sharp and well-maintained cutting tools: Dull blades can cause inaccurate cuts.

- Following established cutting procedures: Consistency is achieved by adhering to standardized techniques.

- Regularly calibrating cutting machines: Ensuring machines are operating at optimal precision.

- Inspecting cut pieces: Checking for accuracy before proceeding to the next step.

- Utilizing measuring tools and templates: For precise measurements and consistent results.

9. Describe the importance of sample cutting in the garment production process.

- Prototyping: Creating physical samples to evaluate design and fit before mass production.

- Quality control: Ensuring accuracy and consistency in garment construction.

- Cost reduction: Identifying and addressing potential issues early on, preventing costly mistakes during production.

- Communication: Facilitating clear communication between designers, pattern makers, and production teams.

10. How do you stay updated with the latest techniques and technologies in sample cutting?

- Attending industry workshops and seminars: Learning from experts and networking.

- Reading trade publications and online resources: Staying informed about new methods and advancements.

- Seeking guidance from experienced mentors: Tapping into the knowledge and expertise of industry professionals.

- Exploring online platforms and forums: Engaging with other sample cutters and exchanging ideas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sample Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sample Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sample Cutter plays a crucial role in the textile industry. Their primary responsibilities involve preparing fabric samples for various purposes, such as quality control, customer approval, and design development. Key job responsibilities include:

1. Sample Preparation

- Accurately cut and prepare fabric samples according to specified dimensions using specialized cutting machines and tools.

- Ensure precise sample cutting to meet required specifications and tolerances.

2. Fabric Analysis

- Examine fabric samples to assess their quality, texture, and appearance.

- Identify and report any defects or inconsistencies in fabric samples.

3. Sample Labeling and Documentation

- Properly label and document fabric samples with relevant information, such as fabric type, color, and lot number.

- Maintain accurate records and track sample status throughout the sampling process.

4. Quality Control

- Collaborate with quality control teams to ensure sample cuttings meet specified standards.

- Conduct visual inspections and perform necessary tests to assess fabric quality.

5. Customer Service

- Interact with customers and understand their sampling requirements.

- Provide timely delivery of fabric samples to meet customer deadlines.

Interview Preparation Tips

To ace an interview for a Sample Cutter position, candidates should focus on demonstrating their technical skills, attention to detail, and industry knowledge. Here are some interview preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and industry trends. This will help you understand the company’s business goals and how the Sample Cutter role contributes to their success.

2. Practice Sample Cutting Techniques

Demonstrate your proficiency in sample cutting techniques. Practice using different cutting machines and tools to ensure you can perform precision cuts accurately. You may also consider preparing samples showcasing your skills.

3. Highlight Attention to Detail

Emphasize your meticulous nature and ability to pay close attention to detail. Sample cutting requires precision and accuracy, so highlight your ability to produce high-quality samples that meet specifications.

4. Discuss Industry Knowledge

Discuss your knowledge of the textile industry, including different fabric types, weaving techniques, and quality control standards. Demonstrating industry knowledge will show the interviewer your understanding of the field.

5. Prepare Questions

Come prepared to ask thoughtful questions during the interview. This shows your interest in the role and the company, and allows you to clarify any details about the job responsibilities.

Example Interview Questions and Answers

Below are some sample interview questions and suggested answers to help you prepare:

Question: Explain your experience in sample cutting and the different types of fabrics you have worked with.

Answer: In my previous role, I was responsible for preparing fabric samples for quality control and customer approval. I have extensive experience in cutting various fabrics, including cotton, linen, silk, and synthetic blends, using cutting machines and hand tools to ensure precise dimensions and quality.

Question: Describe how you ensure the accuracy of your sample cuttings.

Answer: I always start by carefully measuring and marking the fabric according to the specified dimensions. I use sharp cutting tools and specialized equipment to ensure clean and precise cuts. I also double-check my measurements and the overall sample quality before labeling and documenting it.

Question: How do you handle situations where you encounter fabric defects or inconsistencies?

Answer: I am trained to identify and report any fabric defects or inconsistencies promptly. I document the issue, including the type of defect and its location on the sample. I also collaborate with quality control teams to determine the cause and recommend corrective actions.

By following these preparation tips and practicing your answers, you can increase your chances of success in a Sample Cutter interview.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sample Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!