Are you gearing up for a career in Stock Parts Fabricator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Stock Parts Fabricator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

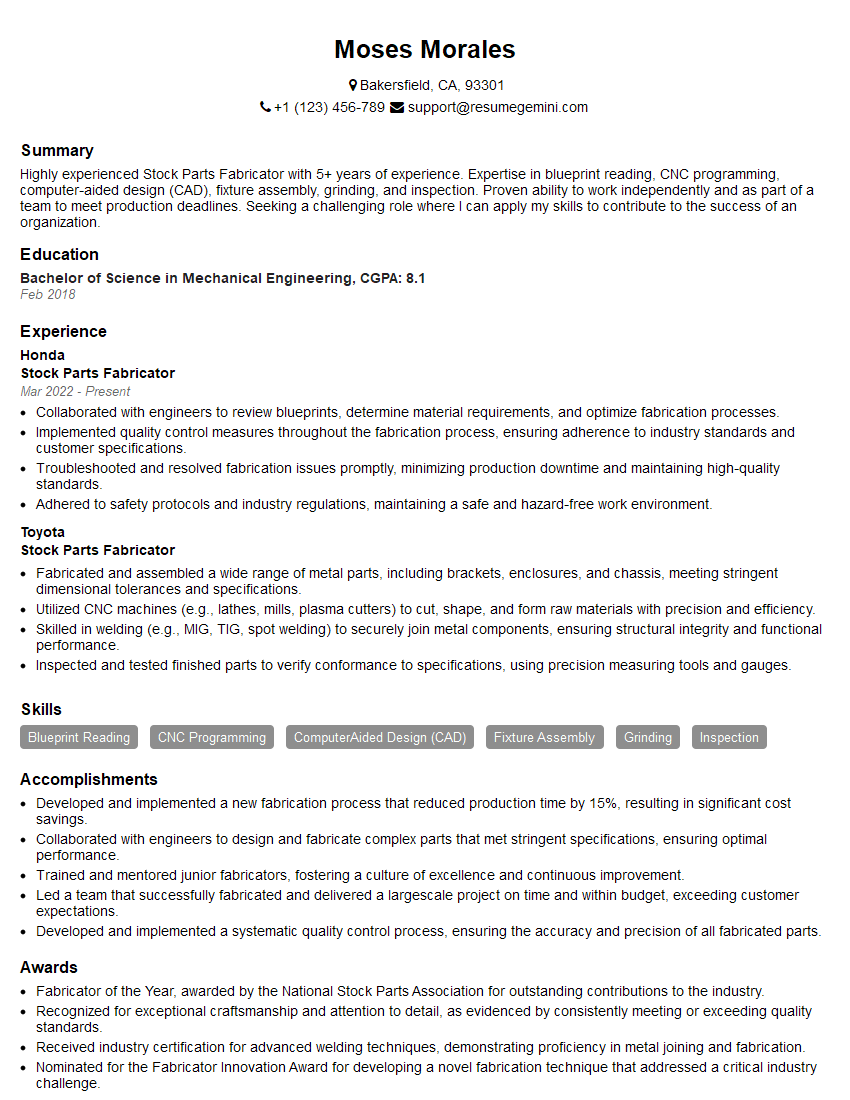

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stock Parts Fabricator

1. What are the different types of stock parts that you have fabricated?

As a Stock Parts Fabricator, I have experience in fabricating a wide range of stock parts, including:

- Gears and shafts

- Bushings and bearings

- Bolts, nuts, and washers

- Springs and clips

- Gaskets and seals

2. What are the different types of materials that you have used to fabricate stock parts?

Metals

- Steel

- Stainless steel

- Aluminum

- Copper

- Brass

Plastics

- Polyethylene

- Polypropylene

- Polyvinyl chloride

- Nylon

- Acetal

3. What are the different manufacturing processes that you have used to fabricate stock parts?

I have experience in a variety of manufacturing processes, including:

- CNC machining

- Manual machining

- Sheet metal fabrication

- Welding

- Assembly

4. What are the quality control procedures that you have followed when fabricating stock parts?

I have followed strict quality control procedures to ensure that all stock parts meet the required specifications. These procedures include:

- Visual inspection

- Dimensional measurement

- Material testing

- Functional testing

5. What are the safety precautions that you have taken when fabricating stock parts?

Safety is a top priority in my work. I have taken the following safety precautions:

- Wearing appropriate PPE

- Using machines safely

- Following established procedures

- Maintaining a clean and organized work area

6. What are your strengths as a Stock Parts Fabricator?

My strengths include:

- Strong technical skills

- Attention to detail

- Ability to work independently and as part of a team

- Commitment to quality

- Excellent communication skills

7. What are your weaknesses as a Stock Parts Fabricator?

I am always looking for ways to improve, but one area where I could use some development is in my experience with exotic materials.

8. What are your career goals as a Stock Parts Fabricator?

My career goal is to become a lead fabricator. I am confident that I have the skills and experience to succeed in this role.

9. What are your salary expectations as a Stock Parts Fabricator?

My salary expectations are in line with the market rate for Stock Parts Fabricators with my experience and skills. I am willing to negotiate a salary that is fair and competitive.

10. Why should we hire you as a Stock Parts Fabricator?

You should hire me because I am a highly skilled and experienced Stock Parts Fabricator. I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stock Parts Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stock Parts Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stock Parts Fabricators play an important role in the manufacturing sector, responsible for creating and maintaining essential parts for machinery and equipment. Their duties include:

1. Fabrication and Assembly

Fabricating and assembling stock parts from raw materials like sheet metal, plastic, or composites.

- Using manual and automated tools to cut, bend, shape, and join materials.

- Assembling components according to specifications and quality standards.

2. Quality Control

Inspecting and ensuring the quality of fabricated parts.

- Using precision measuring instruments and gauges to verify dimensions and tolerances.

- Identifying and correcting any defects or non-conformities.

3. Maintenance and Repair

Maintaining and repairing existing stock parts and equipment.

- Conducting regular inspections and preventive maintenance tasks.

- Troubleshooting and resolving malfunctions or breakdowns.

4. Inventory Management

Managing inventory of raw materials and finished stock parts.

- Monitoring stock levels and placing orders for replenishment.

- Storing and organizing materials and parts efficiently.

Interview Tips

Preparing for an interview as a Stock Parts Fabricator can help you stand out from other candidates. Consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and products. Research the specific job description to understand the key responsibilities and required skills.

- Visit the company website and social media platforms.

- Read industry articles and news about the company and its competitors.

2. Practice Your Technical Skills

Showcase your proficiency in fabrication techniques, quality control procedures, and maintenance tasks. Consider practicing with sample materials or mock-up scenarios.

- Demonstrate your ability to use hand tools, power tools, and measuring instruments.

- Explain your knowledge of welding, metalworking, or composite fabrication techniques.

3. Highlight Your Attention to Detail

Emphasize your strong attention to detail and commitment to accuracy. Provide examples of how you ensure the quality of your work and identify and resolve defects.

- Share specific instances where you detected and corrected errors or non-conformities.

- Describe your experience in using inspection equipment and following quality control protocols.

4. Be Ready for Teamwork

Collaboration is essential in a fabrication environment. Highlight your ability to work effectively in a team setting and contribute to the overall success of the operation.

- Discuss your experience working on collaborative projects or in team-oriented environments.

- Emphasize your communication and interpersonal skills.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Stock Parts Fabricator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.