Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cap Cutter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cap Cutter so you can tailor your answers to impress potential employers.

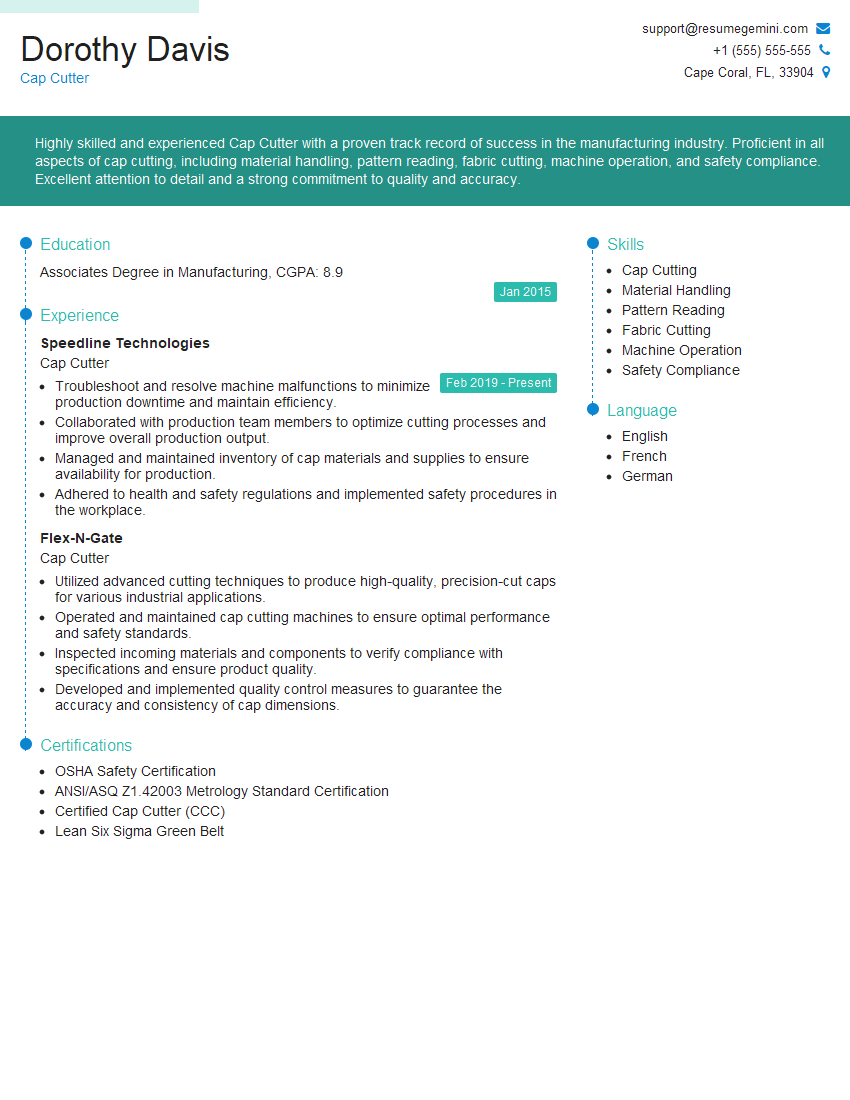

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cap Cutter

1. What is the most important factor to consider when selecting a cap cutter?

- The type of material being cut

- The thickness of the material being cut

- The desired cut quality

- The production volume

- The budget

2. What are the different types of cap cutters?

Types of cap cutters

- Manual cap cutters

- Pneumatic cap cutters

- Hydraulic cap cutters

- Electric cap cutters

Working of the cap cutters

- Manual cap cutters are the most basic type of cap cutter and are operated by hand.

- Pneumatic cap cutters are powered by compressed air and are typically used for high-volume production.

- Hydraulic cap cutters are powered by hydraulic fluid and are typically used for cutting thick materials.

- Electric cap cutters are powered by electricity and are typically used for cutting thin materials.

3. What are the advantages and disadvantages of each type of cap cutter?

- Manual cap cutters are relatively inexpensive and easy to use, but they are not as powerful as other types of cap cutters.

- Pneumatic cap cutters are more powerful than manual cap cutters, but they are also more expensive and require a compressed air supply.

- Hydraulic cap cutters are the most powerful type of cap cutter, but they are also the most expensive and require a hydraulic power unit.

- Electric cap cutters are relatively inexpensive and easy to use, but they are not as powerful as pneumatic or hydraulic cap cutters.

4. What are the safety precautions that should be taken when using a cap cutter?

- Always wear safety glasses when using a cap cutter.

- Keep your hands away from the cutting blade.

- Do not use a cap cutter on materials that are too thick or hard.

- Inspect the cap cutter before each use to ensure that it is in good working condition.

- Never use a cap cutter that is damaged or has loose parts.

5. What are the maintenance procedures that should be performed on a cap cutter?

- Clean the cap cutter after each use.

- Lubricate the cap cutter regularly.

- Inspect the cap cutter for wear and tear.

- Replace the cutting blade when it becomes dull.

6. What are the troubleshooting tips for a cap cutter that is not working properly?

- Check the power supply.

- Check the cutting blade.

- Check the hydraulic fluid.

- Check the air pressure.

7. What are the applications for cap cutters?

- Cutting plastic pipe

- Cutting copper pipe

- Cutting steel pipe

- Cutting aluminum pipe

- Cutting conduit

8. What is the difference between a cap cutter and a pipe cutter?

- Cap cutters are used to cut the ends of pipes, while pipe cutters are used to cut pipes in the middle.

- Cap cutters have a round blade, while pipe cutters have a V-shaped blade.

- Cap cutters are typically used on smaller pipes, while pipe cutters can be used on larger pipes.

9. What is the best way to cut a cap on a pipe?

- Measure the length of the pipe that you need to cut.

- Mark the length on the pipe with a pencil.

- Place the cap cutter on the pipe at the mark.

- Tighten the cap cutter until the blade cuts through the pipe.

- Remove the cap cutter and deburr the edge of the pipe.

10. What are some tips for using a cap cutter?

- Use a sharp blade.

- Apply even pressure when cutting.

- Keep the cap cutter perpendicular to the pipe.

- Deburr the edge of the pipe after cutting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cap Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cap Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cap Cutters are responsible for cutting, trimming, and shaping various types of materials, including paper, plastic, and metal. They may also be responsible for operating and maintaining cutting machinery.

1. Production Planning

Cap Cutters must be able to read and understand production plans and specifications for each job.

- They must be able to determine the correct cutting tools and techniques for each material.

- They must also be able to calculate the correct cutting dimensions based on the production specifications.

2. Cutting Operations

Cap Cutters must be able to operate a variety of cutting machines, including band saws, circular saws, and laser cutters.

- They must be able to set up and adjust the machines to achieve the desired cutting results.

- They must also be able to safely and efficiently operate the machines to produce high-quality cuts.

3. Quality Control

Cap Cutters must be able to inspect and measure cut parts to ensure that they meet the required specifications.

- They must be able to identify and correct any defects in the cutting process.

- They must also be able to document and maintain records of the cutting process for quality control purposes.

4. Equipment Maintenance

Cap Cutters must be able to perform basic maintenance on cutting machinery to ensure that it is operating properly.

- They must be able to clean, lubricate, and adjust the machines as needed.

- They must also be able to identify and report any major issues with the machines to maintenance personnel.

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips for preparing for a Cap Cutter interview:

1. Research the Company and Position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and values, as well as the specific skills and experience they’re looking for in a Cap Cutter.

- Visit the company’s website to learn more about their products, services, and history.

- Read industry publications and news articles to learn about the latest trends and developments in the field.

- Network with people who work in the industry or who have worked for the company in the past.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, regardless of the position you’re applying for. It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills as a Cap Cutter. Be prepared to discuss your previous work experience, as well as any relevant skills or training you have.

- Highlight your experience operating cutting machinery.

- Describe your skills in reading and understanding production plans and specifications.

- Discuss your experience in inspecting and measuring cut parts to ensure quality.

- Mention any training or certifications you have in Cap Cutting.

4. Be Confident and Enthusiastic

It’s important to be confident and enthusiastic during your interview. This will show the interviewer that you’re interested in the position and that you believe in your abilities. However, it’s also important to be humble and to avoid overselling yourself.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be enthusiastic about the position and the company.

- Be humble and don’t oversell yourself.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cap Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.