Feeling lost in a sea of interview questions? Landed that dream interview for Clicker Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Clicker Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

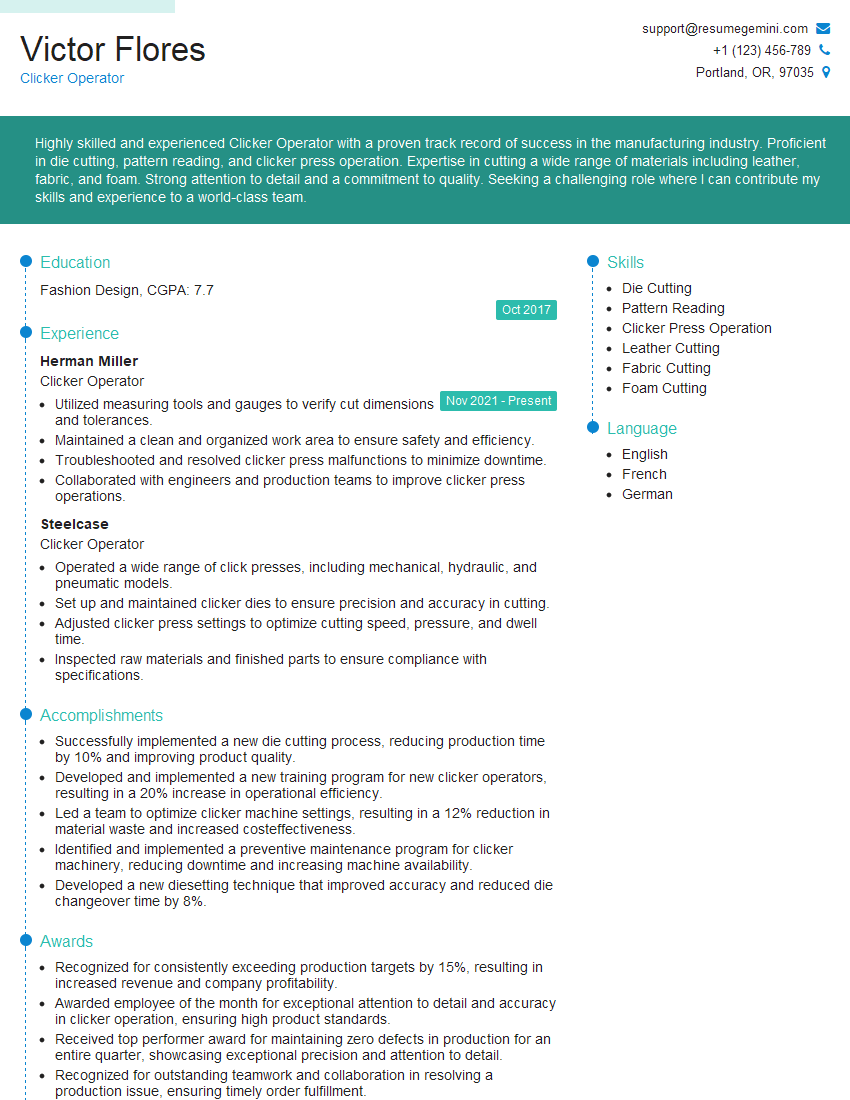

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Clicker Operator

1. Describe the key responsibilities of a Clicker Operator.

- Operating and maintaining clicker machines to cut materials such as fabric, leather, or plastic.

- Setting up and adjusting machines for specific cutting jobs, including selecting dies and blades.

- Monitoring machines during operation and making necessary adjustments to ensure precision cutting.

2. Explain the different types of clicker machines you have worked with and how they differ.

Hydraulic Clicker Machines

- Use hydraulic pressure to apply force to the cutting die.

- Suitable for cutting thick and tough materials.

Electric Clicker Machines

- Use an electric motor to drive the cutting die.

- More suitable for cutting thinner and softer materials.

Laser Clicker Machines

- Use a laser to cut materials.

- Provide high precision and intricate cutting.

3. What are the safety precautions you observe when operating a clicker machine?

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the machine is properly grounded and maintained.

- Keep hands and other body parts away from moving parts.

- Be aware of the location of emergency stop buttons.

4. How do you troubleshoot common problems that may occur during clicker operation?

Machine not cutting properly

- Check blade sharpness and replace if necessary.

- Inspect dies for damage or wear.

- Ensure the material is properly positioned.

Machine overheating

- Check for lubrication issues.

- Allow the machine to cool down.

5. What is the importance of maintaining proper cutting die sharpness?

- Sharper dies produce cleaner and more precise cuts.

- Prevent material damage and reduce waste.

- Ensure consistent cutting quality.

6. How do you determine the correct cutting speed and pressure for different materials?

- Refer to manufacturer’s specifications for the material.

- Experiment with different settings based on material thickness and density.

- Monitor the cutting process and make adjustments as needed.

7. What are the maintenance tasks you perform on a clicker machine?

- Regular cleaning and lubrication.

- Blade sharpening and die inspection.

- Checking hydraulic or electrical systems (depending on the machine type).

- Reporting any issues or concerns to supervisors.

8. How do you ensure that cut materials meet quality standards?

- Inspecting cut pieces for accuracy, cleanliness, and dimensional compliance.

- Using measuring tools and templates for verification.

- Reporting any deviations or defects.

9. What experience do you have in working with automated cutting systems?

- Experience with CNC (Computer Numerical Control) clicker machines.

- Knowledge of programming and operating automated cutting systems.

- Ability to troubleshoot and maintain automated systems.

10. How do you stay updated with the latest advances in clicker technology?

- Attending industry trade shows and conferences.

- Reading technical journals and articles.

- Participating in online forums and discussions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Clicker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Clicker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Clicker Operator is responsible for operating a clicker machine to cut various materials such as leather, fabric, and rubber into specific shapes and sizes.

1. Material Preparation

Prepares materials for cutting by ensuring they are properly aligned and secured on the cutting table.

- Inspects materials for defects or damage.

- Adjusts machine settings based on the material’s thickness and desired cut.

2. Machine Operation

Operates the clicker machine to cut materials according to specified patterns or templates.

- Positions the cutting blade accurately and initiates the cutting process.

- Monitors the cutting process to ensure precision and quality.

3. Quality Control

Inspects cut pieces for accuracy, size, and shape.

- Verifies that cuts meet specified dimensions and tolerances.

- Rejects defective pieces or makes necessary adjustments to the cutting process.

4. Machine Maintenance

Performs basic maintenance on clicker machines.

- Lubricates and cleans machine parts regularly.

- Identifies and reports any mechanical issues or malfunctions.

Interview Tips

To ace the interview for a Clicker Operator position, follow these tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and culture. Understand the specific requirements of the Clicker Operator role and how it aligns with your skills and experience.

- Visit the company’s website and social media pages.

- Read industry publications and articles related to clicker operation.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in clicker machine operation, material preparation, quality control, and basic maintenance. Quantify your accomplishments whenever possible to demonstrate your impact on previous roles.

- Example: “In my previous position, I successfully reduced material waste by 15% through meticulous material preparation and efficient cutting techniques.”

3. Show Attention to Detail and Precision

Clicker operators must possess exceptional attention to detail and precision. Provide examples of your ability to work accurately and meet stringent quality standards.

- Example: “I have a keen eye for identifying even the smallest defects in materials, ensuring that only high-quality cut pieces are produced.”

4. Demonstrate Mechanical Aptitude

Employers value Clicker Operators with a basic understanding of mechanical principles and troubleshooting abilities. Highlight any experience or knowledge you have in this area.

- Example: “I am familiar with the mechanical components of clicker machines and have successfully diagnosed and resolved minor operational issues.”

Next Step:

Now that you’re armed with the knowledge of Clicker Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Clicker Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini