Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cutter Down position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

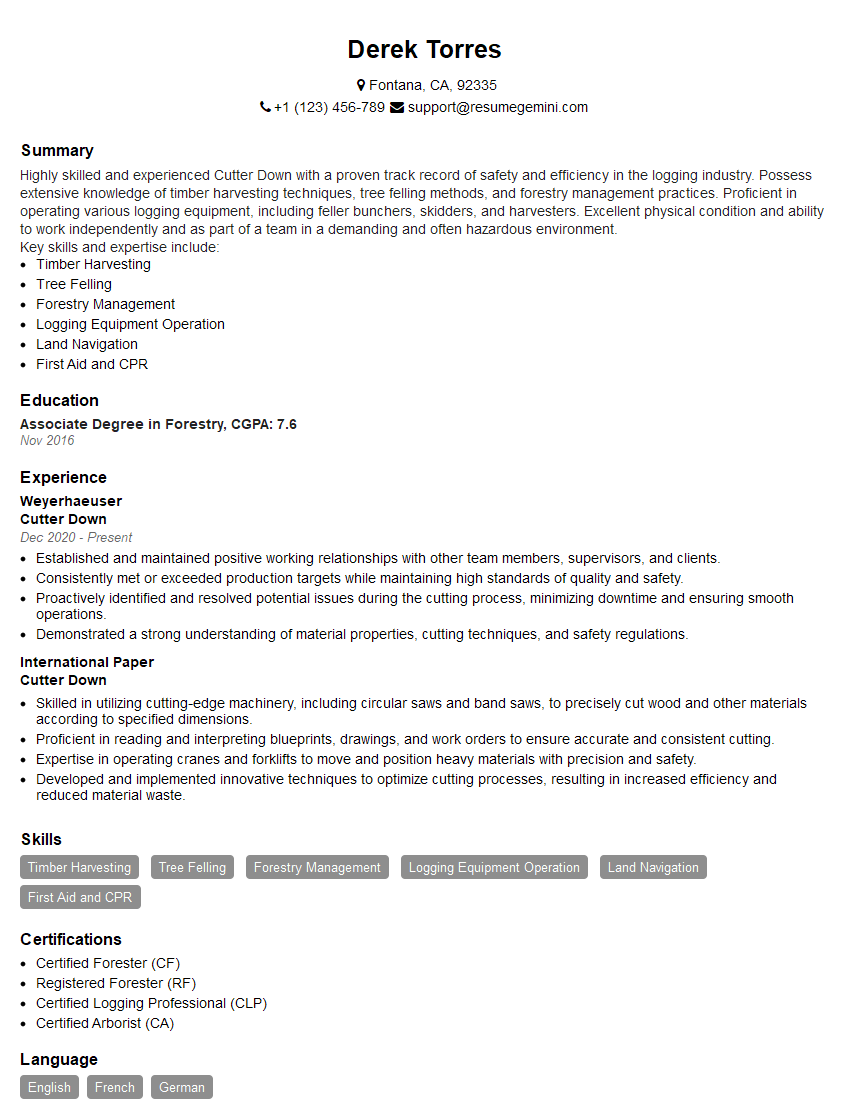

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutter Down

1. How do you determine the correct cutting angle for a specific material?

To determine the correct cutting angle for a specific material, I take into account the following factors:

- Material hardness: Harder materials require a smaller cutting angle to reduce chipping.

- Material thickness: Thicker materials may require a larger cutting angle to prevent deformation.

- Cutter type: Different cutter types have optimal cutting angles for specific materials.

- Cutting speed: Higher cutting speeds often require a smaller cutting angle to avoid overheating.

2. Describe the process of setting up and calibrating a cutting machine?

Setup

- Secure the material in the cutting bed.

- Select the appropriate cutter and install it.

- Adjust the cutting depth and feed rate.

Calibration

- Perform a zero point calibration to align the cutting head to the machine origin.

- Use a test cut to fine-tune the cutting parameters and ensure accuracy.

- Check for alignment and adjust as necessary.

3. How do you handle and store cutting blades safely?

I adhere to the following safety protocols when handling and storing cutting blades:

- Wear appropriate PPE, such as gloves and safety glasses.

- Keep blades sharp and free of debris to prevent accidents.

- Store blades in a designated, secure location away from moisture and potential damage.

- Dispose of dull or damaged blades properly.

4. Explain the difference between a positive and negative cutting rake angle.

A positive cutting rake angle has the cutting edge of the blade inclined away from the workpiece, resulting in a shearing action that reduces cutting force and improves surface finish.

A negative cutting rake angle has the cutting edge of the blade inclined toward the workpiece, creating a more forceful cutting action that is suitable for harder materials or materials requiring higher accuracy.

5. What are the common types of cutting fluids and their applications?

Common types of cutting fluids include:

- Water-based: Economical and environmentally friendly, suitable for light cutting operations.

- Oil-based: Provides lubrication and cooling for heavy-duty cutting, but requires proper disposal.

- Synthetic: Combines the benefits of both water-based and oil-based fluids, offering good lubrication and cooling properties.

- Cryogenic: Liquid nitrogen or carbon dioxide is used as a cutting fluid, providing extreme cooling and reducing tool wear.

6. Describe the principles of chip formation and how it affects cutting efficiency.

Chip formation is the process of removing material in the form of chips during cutting. It affects cutting efficiency as follows:

- Chip shape: Desired chip shape varies depending on the material and cutting conditions. Proper chip formation reduces cutting forces and improves surface finish.

- Chip size: Smaller chips are easier to control and prevent clogging, promoting efficient cutting.

- Chip accumulation: Accumulation of chips can lead to increased cutting forces and tool wear, requiring frequent cleaning.

7. How do you troubleshoot common cutting machine issues, such as vibration or poor surface finish?

To troubleshoot common cutting machine issues:

- Vibration: Check for loose components, worn bearings, or imbalances in the cutting system.

- Poor surface finish: Inspect the cutting tool for dullness or damage, adjust cutting parameters, or consider using a different material.

- Other issues: Refer to the machine’s operator manual for specific troubleshooting steps and consult experienced technicians as needed.

8. What are the advantages and disadvantages of CNC cutting compared to manual cutting?

Advantages of CNC cutting:

- Precision: CNC machines offer high precision and repeatability, ensuring consistent product quality.

- Speed: CNC machines can operate at higher speeds than manual cutting, increasing productivity.

- Automation: CNC machines can automate the cutting process, reducing labor costs and operator error.

Disadvantages of CNC cutting:

- Cost: CNC machines require a significant capital investment.

- Complexity: CNC cutting requires specialized knowledge and programming skills.

- Flexibility: Manual cutting may be more suitable for one-off or small-batch production.

9. Explain the importance of proper maintenance and calibration for cutting machines.

Proper maintenance and calibration of cutting machines are essential for:

- Accuracy: Ensuring the machine consistently produces precise cuts.

- Efficiency: Minimizing downtime and maximizing production output.

- Safety: Identifying and addressing potential malfunctions to prevent accidents.

- Tool life: Regular maintenance extends the lifespan of cutting tools and reduces replacement costs.

10. How do you stay up-to-date on the latest advancements in cutting technology?

I stay up-to-date on cutting technology advancements through:

- Industry conferences and trade shows: Attending these events allows me to learn about new technologies and network with experts.

- Technical publications and webinars: Subscribing to industry magazines and participating in online webinars provides access to the latest research and developments.

- Manufacturer training and certification: Seeking out training and certification opportunities from cutting machine manufacturers ensures I am familiar with their latest products and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutter Down.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutter Down‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A cutter down plays a crucial role in the manufacturing process, performing a range of tasks related to cutting and preparing raw materials.

1. Cutting Raw Materials

The primary responsibility of a cutter down is to cut raw materials, such as fabric, leather, or other materials, into specific shapes and sizes.

- Operate and maintain cutting machines, such as band saws, circular saws, or CNC cutters.

- Read and interpret cutting orders and blueprints to determine the required dimensions and specifications.

2. Preparing Materials for Production

Cutter downs prepare the cut materials for further processing or production.

- Mark or label cut pieces for identification and quality control.

- Stack, bundle, or package cut materials according to specifications.

3. Maintaining Equipment

Cutter downs are also responsible for maintaining the equipment they use.

- Perform routine maintenance and cleaning of cutting machines.

- Report any equipment issues or malfunctions to supervisors promptly.

4. Adhering to Safety Procedures

Safety is paramount in any manufacturing environment.

- Follow all established safety protocols and guidelines.

- Wear appropriate personal protective equipment (PPE).

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success.

1. Research the Company and Position

Take the time to learn about the company’s values, mission, and products/services.

- Visit the company website and social media pages.

- Review the job description thoroughly.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job requirements.

- Quantify your accomplishments whenever possible.

- Practice answering common interview questions.

3. Practice Common Interview Questions

Prepare for common interview questions that could be asked, such as:

- “Tell me about your experience in cutting raw materials.”

- “How do you ensure accuracy and precision in your work?”

- “What is your safety record like?”

4. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving for the interview on time.

- Choose attire that is clean and pressed.

- Plan your route and allow extra time for unexpected delays.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position.

- Inquire about the company’s growth plans.

- Ask about opportunities for professional development.

6. Follow Up

After the interview, send a thank-you note to the interviewer, reiterating your interest in the position.

- Thank the interviewer for their time.

- Reiterate your key qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutter Down interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.