Feeling lost in a sea of interview questions? Landed that dream interview for Flat Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flat Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

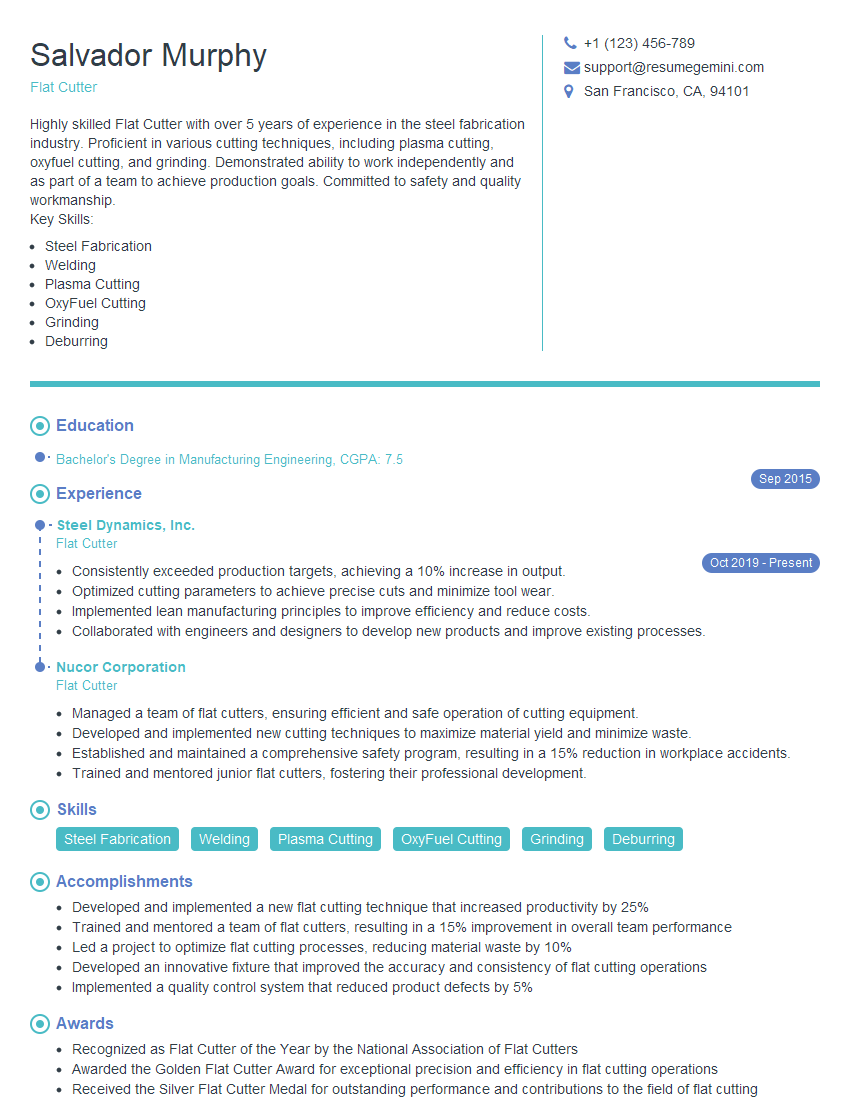

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flat Cutter

1. What are the different types of flat cutters and their applications?

Flat cutters are versatile tools used in various industries and applications. The different types of flat cutters include:

- Standard flat cutters: These are general-purpose cutters used for cutting flat materials such as paper, cardboard, and plastic.

- Specialized flat cutters: These are designed for specific applications, such as cutting fabrics, leather, or metal.

- Power flat cutters: These are motorized cutters that provide increased power and efficiency for heavy-duty cutting tasks.

2. Explain the basic principles of operation of a flat cutter.

A flat cutter operates on the principle of a blade moving against a stationary surface to cut through materials. The blade is typically made of high-strength steel and sharpened to a precise angle. The blade moves rapidly up and down or back and forth, creating a clean and precise cut.

Safety considerations:

- Always wear appropriate safety gear, including eye protection and gloves.

- Keep hands and fingers away from the cutting edge of the blade.

- Use a sharp blade to prevent tearing or fraying of the material.

3. Describe the factors that affect the cutting accuracy of a flat cutter.

The cutting accuracy of a flat cutter is influenced by several factors:

- Blade sharpness: A sharp blade will produce cleaner and more accurate cuts.

- Cutting speed: The speed at which the blade moves affects the cut quality. Too high speed can cause tearing or fraying.

- Material thickness: The thickness of the material being cut can impact the accuracy, as thicker materials may require more force.

- Cutting pressure: The amount of pressure applied to the blade can affect the cut depth and accuracy.

4. How do you maintain and calibrate a flat cutter for optimal performance?

Regular maintenance and calibration are crucial to ensure optimal performance of a flat cutter:

Maintenance:

- Clean the cutter regularly to remove dust and debris.

- Lubricate moving parts to prevent wear and tear.

- Inspect the blade for sharpness and replace it if necessary.

Calibration:

- Check the cutting accuracy periodically and adjust the settings accordingly.

- Calibrate the blade angle to ensure precise cuts.

5. Describe the different materials that can be cut using a flat cutter and the considerations for each material.

Flat cutters can cut a wide range of materials, including:

- Paper and cardboard: These are commonly cut with standard flat cutters.

- Plastics: Specialized flat cutters with hardened blades are used for cutting plastics like acrylic or PVC.

- Fabrics: Flat cutters with sharp, fine blades are used to cut fabrics without fraying the edges.

- Leather: Specialized flat cutters with heavy-duty blades are used to cut leather accurately.

- Thin metals: Power flat cutters with robust blades can cut thin metals like aluminum or copper.

Considerations for different materials:

- Blade sharpness and cutting speed should be adjusted based on the material’s thickness and hardness.

- Use a backing material to support the material during cutting, preventing tearing or deformation.

6. Explain how to troubleshoot common issues with flat cutters, such as dull blades or misalignment.

Common issues with flat cutters and their troubleshooting steps include:

- Dull blades: Replace the blade with a sharp one.

- Misalignment: Adjust the blade angle or cutting surface to correct the alignment.

- Poor cutting accuracy: Check the blade sharpness, cutting speed, and material thickness.

- Excessive noise or vibration: Lubricate moving parts or check for loose components.

7. Describe the safety precautions that should be taken when operating a flat cutter.

To ensure safety when operating a flat cutter:

- Always wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Keep the work area clean and well-lit.

- Secure the material firmly to prevent movement during cutting.

- Never reach over or behind the moving blade.

- Unplug the cutter before making adjustments or replacing blades.

8. What are the advantages of using a flat cutter compared to other cutting tools?

Flat cutters offer several advantages over other cutting tools:

- Precision: They provide highly accurate cuts with minimal distortion or fraying.

- Versatility: They can cut a wide range of materials with different thicknesses and shapes.

- Efficiency: Power flat cutters enable fast and efficient cutting of large volumes of materials.

- Safety: Flat cutters have enclosed blades, reducing the risk of accidents compared to handheld tools.

9. What is the role of software in the operation of a flat cutter?

Software plays a significant role in the operation of modern flat cutters:

- Computer-aided design (CAD) software: Used to design and prepare cutting patterns for the flat cutter.

- Cutting control software: Manages the cutting process, including blade movement, speed, and pressure.

- Optimization software: Optimizes the cutting path to minimize material waste and improve efficiency.

10. How do you stay up-to-date on the latest advancements in flat cutter technology?

To stay informed about advancements in flat cutter technology:

- Attend industry trade shows and conferences.

- Read industry publications and technical journals.

- Connect with manufacturers and suppliers to learn about new products and capabilities.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flat Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flat Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flat Cutters are responsible for operating and maintaining equipment used to flatten steel sheets, ensuring the sheets meet required dimensions and quality standards.

1. Equipment Operation

Operate flat cutting machines to level and smooth steel sheets, adjusting settings as needed to achieve desired results.

- Monitor equipment performance and make necessary adjustments to maintain optimal operating conditions.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

2. Quality Control

Inspect and measure cut sheets to ensure they meet specified dimensions, flatness, and surface finish requirements.

- Use precision measuring tools, such as micrometers and calipers, to verify accuracy.

- Identify and correct any deviations from specifications.

3. Production Management

Manage production schedules to ensure timely delivery of cut sheets.

- Coordinate with production planners to determine workload and prioritize tasks.

- Monitor inventory levels and order materials as needed to support production.

4. Safety and Maintenance

Adhere to safety protocols and regulations to ensure a safe work environment.

- Perform regular maintenance and cleaning of equipment to maintain optimal performance.

- Identify and report any potential hazards or safety concerns.

Interview Tips

Preparing for an interview can be daunting, but following these tips can help you ace the interview and land the job you want.

1. Research the Company and Role

Take some time to research the company’s history, products or services, and industry.

- This will help you understand the company’s culture and values, and tailor your answers to the interviewer’s questions.

- Review the job description carefully and identify the key skills and experiences required for the role.

2. Practice Your Answers

Practice answering common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

- Prepare examples from your experience that highlight your skills and qualifications.

- Be concise and clear in your answers, and avoid using jargon or technical terms that the interviewer may not understand.

3. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive for your interview on time.

- This shows the interviewer that you are respectful of their time and that you take the interview seriously.

- Be polite and courteous to everyone you meet, including the receptionist and other employees.

4. Ask Questions

At the end of the interview, ask the interviewer questions about the role, the company, and the next steps in the hiring process.

- This shows that you are engaged and interested in the position.

- Prepare a few specific questions that you are genuinely interested in asking.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Flat Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.