Are you gearing up for an interview for a Glass Cutting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Cutting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

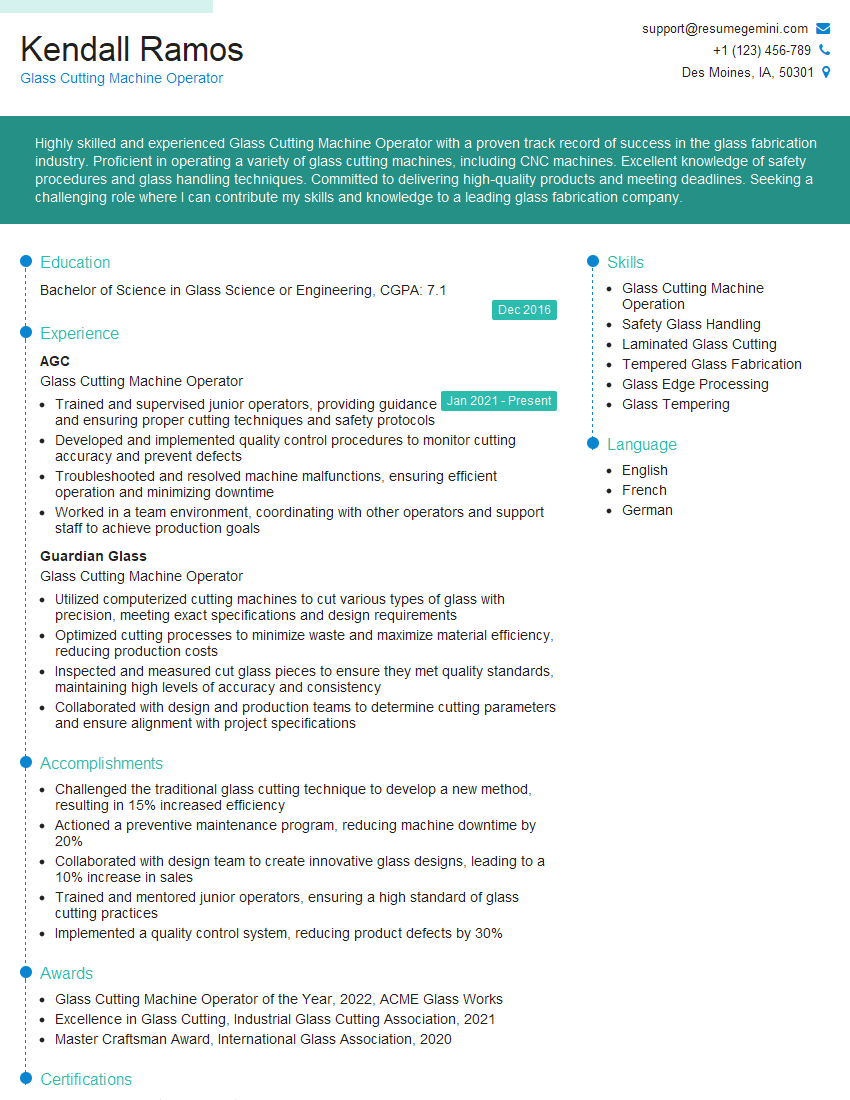

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Cutting Machine Operator

1. What are the different types of glass cutting machines and their uses?

There are several types of glass cutting machines, each designed for specific applications. Here are a few common types and their uses:

- Mechanical Glass Cutting Machine: Uses a rotating diamond-tipped blade to score and cut glass. Suitable for straight cuts, angles, and curves.

- Water Jet Glass Cutting Machine: Employs a high-pressure water jet to cut glass precisely. Ideal for intricate designs, curved cuts, and cutting thick or laminated glass.

- Laser Glass Cutting Machine: Utilizes a concentrated laser beam to melt and cut glass. Offers high precision, smooth edges, and minimal chipping.

- CNC Glass Cutting Machine: A computer-controlled machine that follows pre-programmed designs to cut complex shapes and patterns in glass.

- Handheld Glass Cutting Machine: A portable device used for making quick and simple cuts on smaller pieces of glass.

2. How do you ensure accurate and precise cuts with a glass cutting machine?

Calibrating the Machine

- Calibrate the machine regularly to align the cutting head and other components.

- Use precision measuring tools to verify the accuracy of measurements and cuts.

Using the Correct Blade

- Select the appropriate blade type and size for the thickness and type of glass being cut.

- Regularly inspect blades for wear and tear, and replace them when necessary.

Proper Cutting Technique

- Apply the correct amount of pressure and use smooth, even strokes while cutting.

- Score the glass deeply enough to create a clean break without excessive force.

Handling the Glass

- Handle the glass carefully to avoid chipping or breaking.

- Use gloves to protect your hands and prevent smudging the glass surface.

3. What safety precautions should be taken when operating a glass cutting machine?

- Wear eye protection, such as safety glasses or goggles, to protect against flying glass shards.

- Wear gloves to prevent cuts and lacerations.

- Inspect the machine and ensure it is in good working condition before each use.

- Never leave the machine unattended while it is operating.

- Keep the work area clean and free of debris to prevent slips and falls.

- Follow all manufacturer’s instructions and safety guidelines.

4. How do you troubleshoot common problems encountered when using a glass cutting machine?

- Uneven cuts: Check if the blade is dull or damaged, if the machine is correctly calibrated, and if the cutting speed is appropriate.

- Chipping or breaking: Inspect if the glass is scratched or has internal stresses, apply less pressure while cutting, and ensure you have the correct blade for the glass type.

- Machine malfunction: Check if the power supply is connected properly, inspect the electrical components, and refer to the manufacturer’s manual for specific troubleshooting steps.

5. What factors influence the cutting quality and efficiency of a glass cutting machine?

- Blade type and condition: Use the correct blade for the glass type and ensure it is sharp and free from defects.

- Machine calibration: Regular calibration ensures accurate cutting and prevents deviations.

- Glass quality: Glass with fewer scratches, internal stresses, and impurities results in better cutting quality.

- Cutting speed and pressure: Adjust the cutting speed and pressure based on the glass thickness and type to minimize chipping and breakage.

- Maintenance: Proper maintenance, including lubrication and cleaning, ensures optimal machine performance and longevity.

6. How do you maintain a glass cutting machine to ensure its optimal performance?

- Regular cleaning: Remove glass shards, dust, and other debris from the machine and work area.

- Blade inspection: Check blades for wear and tear, and replace them as needed.

- Oil and lubrication: Follow the manufacturer’s recommended lubrication schedule to keep machine components running smoothly.

- Calibration: Periodically calibrate the machine to maintain accuracy and prevent misalignment.

- Electrical maintenance: Ensure electrical connections are secure and inspect wires for damage.

7. What is the difference between annealed and tempered glass, and how does it affect the cutting process?

- Annealed glass: Standard glass that has undergone a cooling process to relieve internal stresses, making it less brittle and more resistant to thermal breakage.

- Tempered glass: Strengthened glass that has undergone a heating and cooling process, increasing its strength and making it more resistant to impact and thermal stress.

- Cutting differences: Tempered glass is more difficult to cut than annealed glass due to its increased hardness. Special blades and techniques are required to cut tempered glass safely and effectively.

8. How do you handle and store cut glass safely to prevent damage?

- Wear gloves: Protect hands from sharp edges and prevent smudging the glass surface.

- Use protective materials: Wrap cut glass in bubble wrap, foam, or other protective materials to prevent scratches and breakage.

- Store vertically: Store cut glass vertically, on edge, to minimize the risk of bending or warping.

- Avoid contact: Keep cut glass pieces separated to prevent chipping or scratching.

- Proper handling: Always handle cut glass with care, avoid excessive force or sudden movements.

9. What is your experience with different types of glass cutting software?

I have experience with several glass cutting software programs, including:

- GlassCAM: A specialized software for cutting complex shapes and patterns in glass.

- AutoCAD: A computer-aided design (CAD) software used for creating and editing 2D and 3D models, which can be utilized for glass cutting.

- Vectric Aspire: A software designed for CNC machines and is capable of generating cutting paths for intricate glass designs.

10. How do you optimize cutting patterns to minimize material waste?

To optimize cutting patterns and minimize material waste, I follow these strategies:

- Nesting algorithms: Use software tools that employ nesting algorithms to automatically arrange cutting patterns to minimize wasted space.

- Manual optimization: Manually adjust and rotate cutting patterns to fit as many pieces as possible within the available glass sheet.

- Consider glass size: Take into account the dimensions of the glass sheet and available cutting area when designing patterns to reduce excess material.

- Use smaller pieces: Incorporate smaller pieces into the cutting pattern to utilize leftover glass from previous cuts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Cutting Machine Operators are responsible for operating and maintaining glass cutting machines to cut glass into various shapes and sizes.

1. Operating Glass Cutting Machines

Loading glass sheets onto the cutting machine.

- Programing the machine to cut the glass according to specified dimensions and shapes.

- Operating the machine to cut the glass accurately and efficiently.

- Monitoring the cutting process to ensure quality and accuracy.

2. Inspecting and Measuring Glass

Inspecting cut glass for defects or imperfections.

- Measuring the cut glass to ensure it meets specifications.

- Identifying and reporting any quality issues or deviations from specifications.

3. Maintaining Glass Cutting Machines

Cleaning and lubricating the glass cutting machine regularly.

- Performing minor repairs and adjustments to keep the machine in good working order.

- Reporting any major maintenance or repair issues to supervisors.

4. Material Handling

Lifting and moving glass sheets safely and efficiently.

- Storing and organizing glass sheets in a designated area.

- Using proper material handling equipment to ensure safety and minimize breakage.

Interview Tips

Preparing for a Glass Cutting Machine Operator interview requires candidates to understand the key job responsibilities, industry-specific knowledge, and common interview questions. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products or services, and industry trends.

- Research the specific type of glass cutting machine used by the company.

- Understand the industry standards and regulations related to glass cutting.

2. Practice Answering Common Interview Questions

Review and prepare answers to common interview questions, such as:

- “Tell me about your experience operating glass cutting machines.”

- “What are the most important safety precautions to follow when operating a glass cutting machine?”

- “How do you handle and measure glass sheets to ensure accuracy?”

- “What maintenance tasks do you perform to keep the glass cutting machine in good working order?”

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job, such as:

- Expertise in operating glass cutting machines.

- Knowledge of glass cutting techniques and principles.

- Experience in inspecting and measuring glass products.

- Ability to maintain and repair glass cutting machines.

- Strong attention to detail and accuracy.

4. Demonstrate Your Safety Awareness

Stress the importance of safety when working with glass cutting machines.

- Discuss your knowledge of safety protocols and regulations.

- Explain how you prioritize safety in your work and ensure a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Cutting Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.