Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Insulation Cutter and Former position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

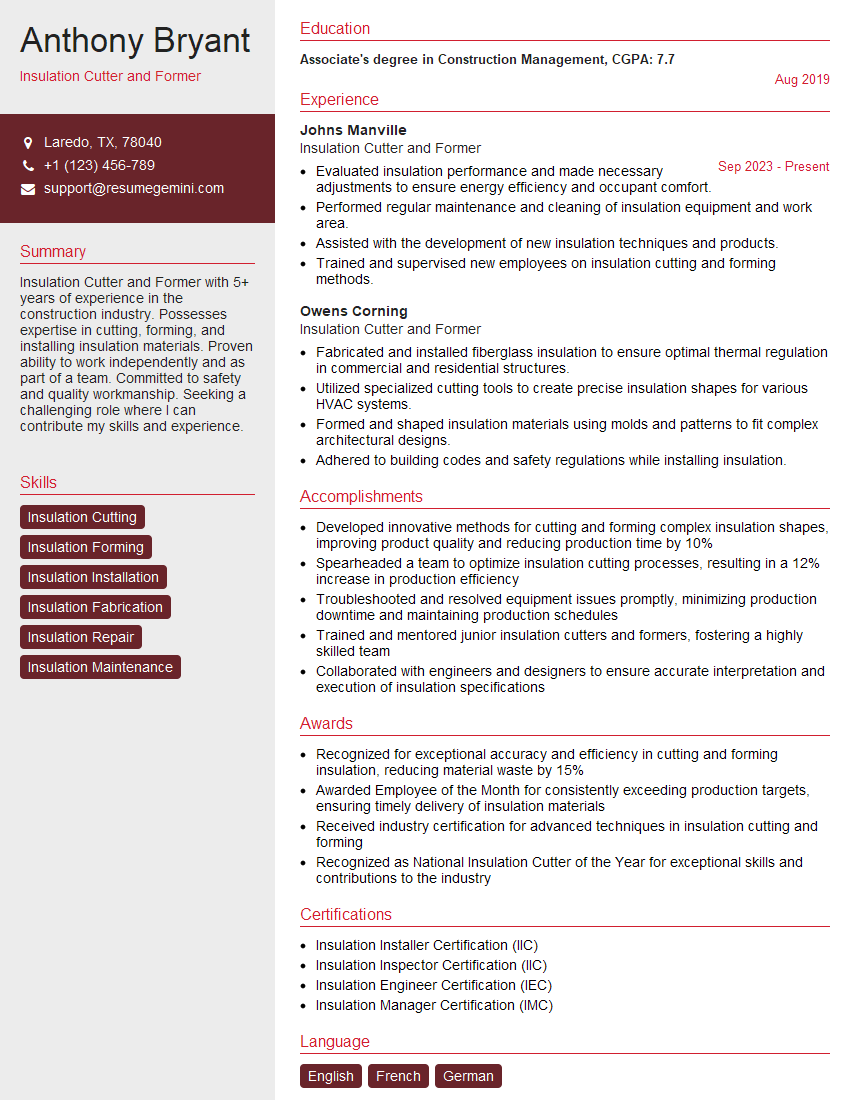

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Cutter and Former

1. Explain the process of insulation cutting and forming?

- The insulation cutting and forming process involves using specialized equipment to cut and shape insulation materials according to specified dimensions and shapes.

- The process typically begins with the selection of the appropriate insulation material, which can vary depending on the application.

- Once the material is selected, it is placed on a cutting table and cut using a precision cutting tool.

- The cutting tool can be a manual or automated device, and the cutting parameters (such as speed, pressure, and angle) are carefully controlled to ensure accurate and consistent results.

- After cutting, the insulation material is then formed into the desired shape using a forming machine.

- The forming machine can be a press, a mold, or a combination of both, and it applies pressure and heat to shape the insulation material into the desired configuration.

- The forming process requires precise control of temperature, pressure, and timing to ensure the formation of high-quality insulation components.

2. What types of insulation materials are commonly cut and formed?

Types of Insulation Materials

- Fiberglass

- Mineral wool

- Polystyrene

- Polyurethane

- Polyethylene

Commonly Cut and Formed Shapes

- Batts and rolls

- Boards and panels

- Pipes and tubes

- Custom shapes and sizes

3. What are the key factors to consider when selecting an insulation cutting and forming machine?

- The type and thickness of the insulation material

- The desired shape and size of the insulation components

- The production volume and throughput requirements

- The level of automation and precision required

- The budget and space constraints

4. Describe the safety precautions that should be followed when operating insulation cutting and forming equipment.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask.

- Ensure that the equipment is properly grounded and maintained.

- Follow the manufacturer’s instructions for operating the equipment safely.

- Be aware of the potential hazards associated with the equipment, such as sharp blades and moving parts.

- Never operate the equipment while under the influence of alcohol or drugs.

- Keep the work area clean and free of debris.

5. What are the common troubleshooting tips for insulation cutting and forming equipment?

- Check the cutting blades for sharpness and replace them if necessary.

- Adjust the cutting parameters (such as speed, pressure, and angle) to optimize performance.

- Clean the equipment regularly to remove dust and debris.

- Lubricate moving parts according to the manufacturer’s instructions.

- Check the electrical connections and ensure that the equipment is properly grounded.

- Refer to the manufacturer’s user manual for specific troubleshooting tips.

6. How do you ensure the quality of insulation components produced using cutting and forming equipment?

- Establish and follow documented quality control procedures.

- Use calibrated measuring instruments to verify the dimensions and shapes of the insulation components.

- Inspect the insulation components for defects such as tears, gaps, or contamination.

- Maintain records of the quality control checks performed.

- Continuously improve the quality control process based on feedback and data analysis.

7. What are the latest advancements in insulation cutting and forming technology?

- Automated cutting and forming machines with high precision and throughput.

- Computer-controlled systems for optimizing cutting parameters and minimizing waste.

- Advanced materials with improved insulation properties and formability.

- Environmentally friendly cutting and forming processes that reduce emissions.

- Integration of robotics and artificial intelligence for automated quality control.

8. How do you stay up-to-date with the latest trends and developments in the insulation cutting and forming industry?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Network with professionals in the field.

- Participate in online forums and discussion groups.

- Conduct research and development to explore new technologies and applications.

9. What are the challenges involved in the insulation cutting and forming process?

- Ensuring precision and accuracy in cutting and forming.

- Minimizing waste and optimizing material utilization.

- Dealing with different types and thicknesses of insulation materials.

- Maintaining high production rates while ensuring quality.

- Complying with safety regulations and environmental standards.

10. How do you handle situations where the insulation cutting and forming equipment malfunctions?

- Identify the source of the malfunction and assess the severity of the issue.

- Follow established troubleshooting procedures.

- Contact the equipment manufacturer or a qualified technician for assistance if necessary.

- Document the malfunction and any corrective actions taken.

- Implement preventive maintenance measures to minimize the risk of future malfunctions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Cutter and Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Cutter and Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Cutters and Formers play a crucial role in the manufacturing process, ensuring the production of high-quality insulation materials. Their key responsibilities encompass:

1. Insulation Cutting

Using specialized cutting machines, they precisely cut insulation materials, such as fiberglass, rock wool, and polystyrene, into desired shapes and sizes. Accurate cutting is crucial for achieving dimensional specifications and minimizing material waste.

- Operate cutting machines and adjust settings to achieve precise cuts.

- Interpret blueprints and follow specifications to cut insulation to exact dimensions.

2. Insulation Forming

After cutting, these professionals shape insulation materials into specific forms to meet design requirements. They utilize techniques like molding, bending, and laminating to create complex shapes and ensure proper fit and function.

- Mold insulation into various shapes using specialized molds or forming equipment.

- Bend and laminate insulation materials to create custom shapes and configurations.

3. Equipment Maintenance

Insulation Cutters and Formers also maintain cutting and forming equipment by performing routine inspections, cleaning, and adjustments. This ensures optimal performance, minimizes downtime, and extends the lifespan of costly equipment.

- Inspect and clean cutting and forming machines to ensure proper functioning.

- Adjust and calibrate equipment to maintain accuracy and efficiency.

4. Quality Control

They conduct quality control checks on finished insulation products to verify that they meet established specifications. This involves visual inspections, dimensional measurements, and testing the insulation’s thermal performance.

- Inspect insulation cuts and forms for defects, ensuring they meet quality standards.

- Measure and verify dimensions to ensure accuracy and compliance with specifications.

Interview Tips

To ace your interview as an Insulation Cutter and Former, follow these key tips:

1. Research the Company and Position

Thoroughly research the company you’re applying to and the specific position you’re seeking. This will help you understand their business, values, and the requirements of the role. Tailoring your answers to the company’s needs and the job’s responsibilities will make a positive impression.

- Visit the company’s website to learn about their history, services, and industry standing.

- Review the job description carefully and highlight the skills and experience that are most relevant to the position.

2. Quantify your Accomplishments

When describing your previous experience, focus on quantifying your accomplishments whenever possible. This will provide tangible evidence of your contributions and impact on the organization. For example, instead of saying “I was responsible for insulation cutting,” you could say “I cut over 10,000 pieces of insulation per shift, achieving a 99% accuracy rate.”

- Use specific numbers and metrics to demonstrate the impact of your work.

- Provide examples of successful projects or initiatives you were involved in.

3. Highlight your Attention to Detail

Insulation Cutters and Formers must possess a keen eye for detail to ensure accurate cuts and forms. During the interview, emphasize your attention to detail and ability to work with precision. Share examples of how you meticulously follow instructions, check your work, and maintain high standards of accuracy.

- Describe situations where you consistently met or exceeded quality standards.

- Mention any certifications or training programs you have completed that demonstrate your commitment to precision.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the actual interview. Some common questions for Insulation Cutters and Formers include:

- Tell me about your experience in insulation cutting and forming.

- How do you ensure the accuracy of your cuts and forms?

- What do you do when you encounter a problem with the cutting or forming equipment?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insulation Cutter and Former interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!