Feeling lost in a sea of interview questions? Landed that dream interview for Ripshear Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ripshear Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

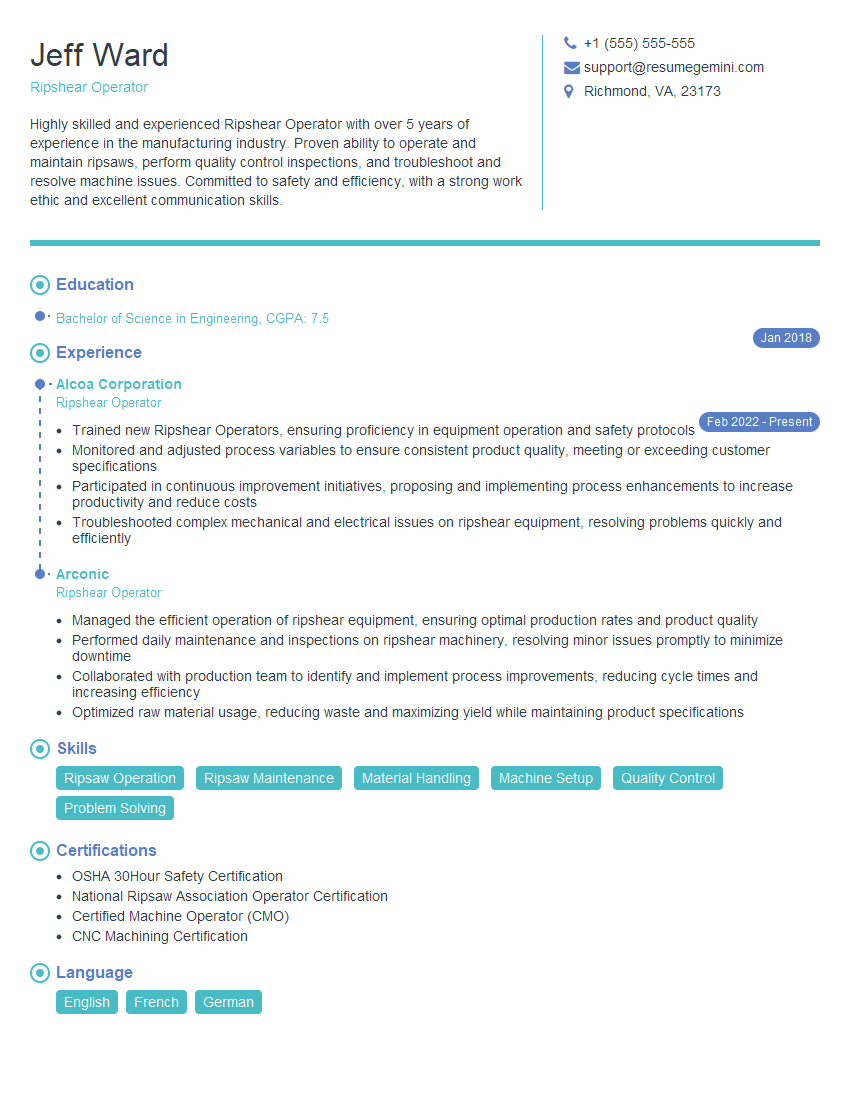

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ripshear Operator

1. Explain the key responsibilities of a Ripshear Operator?

The primary responsibilities of a Ripshear Operator include:

- Operating ripshear equipment to remove overburden and expose coal seams

- Maintaining and repairing ripshear equipment

- Monitoring equipment performance and making necessary adjustments

- Ensuring safe and efficient operation of the ripshear

- Working closely with other mining personnel to ensure smooth operation of the mine

2. Describe the different types of ripshear equipment and their uses?

There are several types of ripshear equipment used in mining operations:

Single-Pass Ripshears

- Designed for removing overburden in a single pass, exposing coal seams efficiently

- Equipped with rotating cutting heads that break down overburden into smaller pieces

Multi-Pass Ripshears

- Used for removing thicker layers of overburden, making multiple passes to expose the coal seam

- Equipped with multiple cutting heads arranged in a staggered configuration

Ripshear Augers

- Combination of a ripshear and an auger, rotating cutting heads break down overburden while augers convey the material away

- Suitable for removing overburden containing large rocks or other hard materials

3. What are the safety precautions that must be followed when operating a ripshear?

Safety is paramount when operating ripshear equipment, and several precautions must be followed to ensure the safety of the operator and others:

- Wearing appropriate personal protective equipment (PPE) including a hard hat, safety glasses, gloves, and high-visibility clothing

- Ensuring the ripshear is in good working condition and regularly maintained

- Inspecting the work area before operating the ripshear to identify potential hazards

- Maintaining a safe distance from the cutting area and other equipment

- Following established safety protocols and adhering to company safety regulations

4. How do you maintain and troubleshoot ripshear equipment?

Regular maintenance and timely troubleshooting are crucial for ensuring optimal performance and safety of ripshear equipment:

Maintenance

- Regularly inspecting cutting heads for wear and tear, and replacing as needed

- Maintaining hydraulic systems and ensuring proper lubrication

- Monitoring fluid levels and changing fluids according to manufacturer’s recommendations

Troubleshooting

- Identifying and resolving common issues such as hydraulic leaks, cutting head blockages, or electrical faults

- Using diagnostic tools and manuals to identify the root cause of problems

- Performing repairs or contacting qualified technicians for major issues

5. What are the different types of ground conditions that can affect ripshear operation?

Ground conditions play a significant role in ripshear operation, and understanding the different types of conditions is crucial:

- Soft Ground: Loose soil or sand, easy to cut, requires minimal force

- Hard Ground: Compact soil or rock, requires more force to cut, can cause wear on cutting heads

- Wet Ground: Saturated ground can reduce traction and increase resistance, affecting ripshear performance

- Frozen Ground: Permafrost or frozen soil, very hard to cut, requires specialized cutting heads

- Mixed Ground: Combinations of different ground conditions, requiring adjustments in cutting parameters

6. How do you adjust ripshear settings to optimize performance based on ground conditions?

Optimizing ripshear performance requires adjusting settings based on ground conditions:

- Cutting Depth: Adjusting the depth of the cutting head based on overburden thickness and ground conditions

- Cutting Speed: Adjusting the speed of the cutting head to match ground hardness and avoid excessive wear

- Cutting Angle: Setting the angle of the cutting head to maximize efficiency and minimize ground resistance

- Cutting Pressure: Adjusting the pressure applied by the cutting head to match ground hardness and prevent overloading

- Water Injection: Using water injection to reduce dust and improve cutting efficiency in hard ground

7. How do you monitor ripshear performance and identify potential issues?

Monitoring ripshear performance is crucial for maintaining efficiency and preventing problems:

- Regularly monitoring cutting depth, speed, and pressure to ensure optimal performance

- Inspecting cutting heads for wear and tear, and replacing as needed

- Listening for unusual noises or vibrations that may indicate potential issues

- Observing ground conditions and adjusting settings accordingly to maintain efficiency

- Tracking maintenance history and performing preventive maintenance to avoid breakdowns

8. How do you work effectively as part of a mining team?

Collaboration and teamwork are essential in mining operations:

- Communicating effectively with other team members to coordinate activities

- Understanding and following instructions from supervisors and colleagues

- Providing support to other team members when needed

- Participating in team meetings and discussions to share knowledge and ideas

- Maintaining a positive and cooperative work environment

9. What are the environmental considerations when operating a ripshear?

Environmental awareness is important in mining operations:

- Minimizing noise and dust generation through proper maintenance and water injection

- Protecting water sources and preventing contamination from spills or leaks

- Rehabilitating disturbed areas after mining operations are complete

- Adhering to environmental regulations and best practices

- Participating in environmental monitoring programs

10. How do you stay updated on the latest ripshear technologies and best practices?

Continuous learning is crucial in the mining industry:

- Attending industry conferences and workshops

- Reading technical journals and articles

- Participating in online forums and discussions

- Consulting with equipment manufacturers and experts

- Seeking opportunities for professional development and training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ripshear Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ripshear Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ripshear Operators play a vital role in maintaining the smooth and efficient operation of pulp and paper mills.

1. Machine Operation

Operate and maintain ripshear machines, ensuring optimal performance and production output.

- Calibrate and adjust machine settings to meet production specifications.

- Monitor machine performance and identify potential problems, taking corrective actions promptly.

2. Pulp Quality Control

Monitor and control the quality of pulp produced by the ripshear machine.

- Conduct quality tests on the pulp, such as fiber length, consistency, and brightness.

- Make adjustments to machine settings and feedstock blend to achieve the desired pulp quality.

3. Maintenance and Troubleshooting

Perform regular maintenance and troubleshooting on ripshear machines.

- Lubricate and inspect machine components, replacing worn parts as necessary.

- Identify and resolve machine malfunctions, minimizing downtime and ensuring smooth production.

4. Safety and Compliance

Maintain a safe and compliant work environment, adhering to company policies and regulations.

- Follow established safety protocols for machine operation and maintenance.

- Monitor compliance with environmental regulations, ensuring proper waste disposal and adherence to emission standards.

Interview Preparation Tips

To ace the Ripshear Operator interview, it’s essential to prepare thoroughly by researching the role and practicing your answers.

1. Research the Company and Industry

Gather information about the company’s history, mission, and products.

- Research industry trends and recent developments in ripshear technology.

- Familiarize yourself with the specific requirements of the role you’re applying for.

2. Highlight Your Experience and Skills

Tailor your resume and cover letter to the job description, emphasizing your relevant experience and skills.

- Quantify your accomplishments using specific metrics, such as production increases or reduction in downtime.

- Showcase your proficiency in ripshear machine operation, maintenance, and quality control.

3. Prepare for Technical Questions

Anticipate technical questions related to ripshear operations, such as:

- Describe the key components and functions of a ripshear machine.

- How do you optimize machine settings to achieve the desired pulp quality?

- What maintenance procedures are essential for ripshear machines?

4. Practice Your Interview Skills

Practice answering common interview questions to build your confidence and fluency.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Prepare questions for the interviewer to demonstrate your interest and engagement in the position.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview.

- Choose clothing that is appropriate for the workplace and industry.

- Be punctual to show respect for the interviewer’s time and commitment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ripshear Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!