Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rock Cutter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rock Cutter so you can tailor your answers to impress potential employers.

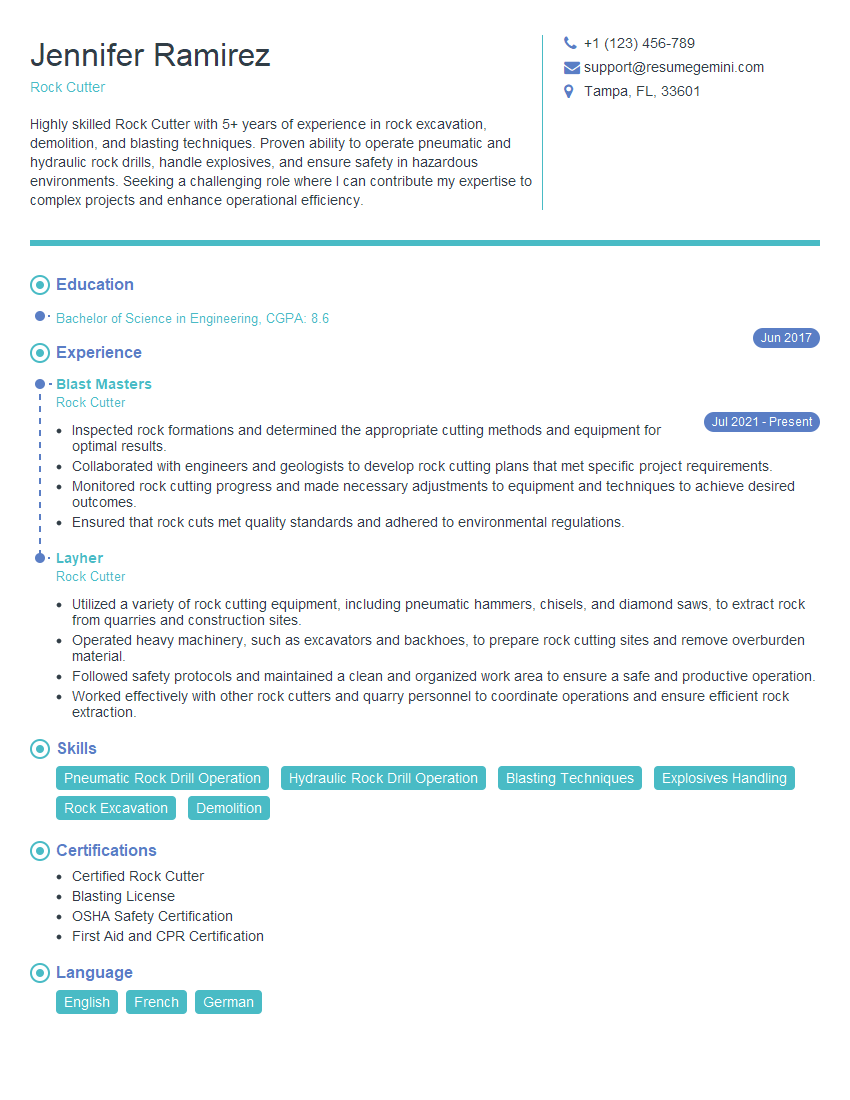

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rock Cutter

1. What techniques do you employ to select the optimal rock cutting equipment for a given project?

To select the optimal rock cutting equipment for a project, I consider the following factors:

- Rock type and hardness: Different rock types require different cutting methods and equipment. I assess the hardness and properties of the rock to determine the most suitable cutting technique.

- Project requirements: The desired cut size, shape, and accuracy influence the choice of equipment. I analyze the project specifications to ensure the selected equipment meets these requirements.

- Site conditions: Factors such as accessibility, space constraints, and environmental regulations impact equipment selection. I evaluate site conditions to determine the most feasible and efficient equipment.

- Budget and timeline: The project’s budget and timeline influence the choice of equipment. I consider cost-effectiveness and rental or purchase options to optimize resources.

- Safety and environmental concerns: I prioritize safety and environmental compliance. I select equipment that adheres to safety standards and mitigates environmental impact.

2. Describe the different types of rock cutting methods and their applications.

Mechanical Cutting

- Percussion Drilling: Uses a hammer and chisel to break rock into smaller pieces.

- Rotary Drilling: Uses a rotating bit to cut through rock.

- Wire Sawing: Uses a diamond-impregnated wire to cut through rock.

Thermal Cutting

- Plasma Cutting: Uses a plasma torch to melt and cut through rock.

- Laser Cutting: Uses a laser to vaporize and cut through rock.

Chemical Cutting

- Chemical Injections: Uses acids or alkalis to dissolve rock.

3. What safety precautions and best practices should be followed when operating rock cutting equipment?

- Wear appropriate Personal Protective Equipment (PPE): including safety glasses, hard hat, gloves, and ear protection.

- Inspect equipment regularly: Check for any damage or malfunctions before use.

- Establish a clear work area: Ensure the work area is free from obstacles and hazards.

- Follow manufacturer’s instructions: Read and understand the equipment manual thoroughly.

- Handle equipment properly: Use proper lifting techniques and avoid overloading equipment.

- Be aware of environmental conditions: Consider factors such as dust, noise, and weather conditions.

- Have an emergency plan in place: Identify potential hazards and establish procedures for emergencies.

4. How do you maintain and troubleshoot common problems with rock cutting equipment?

- Regular maintenance: Follow manufacturer’s recommendations for maintenance, including lubrication, cleaning, and filter changes.

- Troubleshooting: If equipment malfunctions, identify common problems and their solutions. For example, if a drill bit is jammed, check for obstructions or replace the bit.

- Preventative measures: Implement measures to prevent problems from occurring, such as using high-quality materials and inspecting equipment regularly.

5. What environmental considerations should be taken into account when using rock cutting equipment?

- Noise pollution: Use noise-dampening equipment or schedule operations during less disruptive hours.

- Dust and debris: Implement dust suppression measures, such as using water or dust collectors.

- Vibration: Minimize vibration by using dampening materials or isolating equipment from sensitive areas.

- Waste disposal: Properly dispose of rock cuttings and other waste materials according to environmental regulations.

6. What are some recent advancements and trends in rock cutting technology?

- Automated cutting systems: Use robotics and automation to improve precision and efficiency.

- New cutting tools: Development of advanced cutting tools, such as diamond-impregnated bits and laser cutting systems.

- Digital modeling and simulation: Use of 3D modeling and simulation software to optimize cutting processes.

- Environmental sustainability: Focus on developing more environmentally friendly cutting methods and equipment.

7. How do you stay up to date with the latest advancements and best practices in rock cutting?

- Attend industry events and conferences: Network with professionals and learn about new technologies.

- Subscribe to industry publications and journals: Stay informed about the latest research and developments.

- Utilize online resources: Explore websites, forums, and social media platforms to gather information.

8. What is your approach to managing a team of rock cutters?

- Leadership: Provide clear direction, motivation, and support to the team.

- Communication: Maintain open and regular communication to ensure everyone is aligned and informed.

- Delegation: Assign tasks and responsibilities based on individual strengths and capabilities.

- Safety: Emphasize safety protocols and ensure all team members follow best practices.

9. How do you handle challenging projects or unexpected obstacles during rock cutting operations?

- Assessment: Analyze the situation and identify the root cause of the challenge.

- Problem-solving: Explore alternative solutions and develop a plan to overcome the obstacle.

- Communication: Keep stakeholders informed and coordinate efforts to address the challenge.

- Adaptability: Adjust plans and processes as needed to accommodate unforeseen circumstances.

10. Describe a project where you successfully implemented an innovative or efficient rock cutting technique.

In a recent project, we encountered a challenging rock formation that required precise and efficient cutting. I researched and identified a newly developed laser cutting system that promised higher accuracy and reduced waste. By implementing this innovative technique, we were able to achieve cleaner cuts, minimize environmental impact, and complete the project ahead of schedule.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rock Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rock Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rock Cutters play a pivotal role in the construction and mining industries by performing critical tasks related to rock excavation and extraction. Their key responsibilities encompass:

1. Rock Excavation

Using specialized equipment like jackhammers, drills, and explosives, Rock Cutters break down large pieces of rock into smaller, manageable fragments.

- Operate and maintain jackhammers, drills, and blasting equipment

- Drill boreholes, insert explosives, and detonate them to break rock

2. Rock Fragmentation

Rock Cutters further reduce the size of rock fragments using hydraulic splitters, hammers, and crushers, preparing them for use or disposal.

- Use hydraulic splitters to break large rocks into smaller pieces

- Operate hammers and crushers to reduce rocks to desired sizes

3. Site Preparation

They prepare excavation sites by clearing vegetation, removing obstacles, and creating access routes for heavy machinery.

- Clear vegetation, rocks, and other obstacles from excavation sites

- Establish access routes for heavy equipment and materials

4. Equipment Maintenance

Rock Cutters are responsible for maintaining and repairing the equipment they use, ensuring its optimal performance and safety.

- Inspect, clean, and lubricate equipment regularly

- Identify and resolve equipment malfunctions and breakdowns

Interview Tips

To ace an interview for a Rock Cutter position, candidates should prepare thoroughly and present themselves professionally. Here are some essential interview tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company and the rock cutting industry. Research the company’s projects, their safety record, and the specific role you are applying for.

- Visit the company’s website and social media pages

- Read industry publications and news articles

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in rock cutting and related areas. Quantify your accomplishments and provide specific examples whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences

- Highlight your expertise in operating and maintaining rock cutting equipment

3. Showcase Safety Awareness

Rock cutting is a hazardous profession. Emphasize your commitment to safety and your understanding of industry regulations and best practices.

- Discuss your safety training and certifications

- Describe your experience in following safety protocols and preventing accidents

4. Prepare for Technical Questions

Be prepared to answer technical questions about rock cutting techniques, equipment, and safety measures. Practice using industry terminology and explaining complex concepts in a clear and concise manner.

- Review common rock cutting methods and equipment

- Study safety regulations and best practices for rock cutting

Next Step:

Now that you’re armed with the knowledge of Rock Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rock Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini