Are you gearing up for a career in Rubber Splicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rubber Splicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

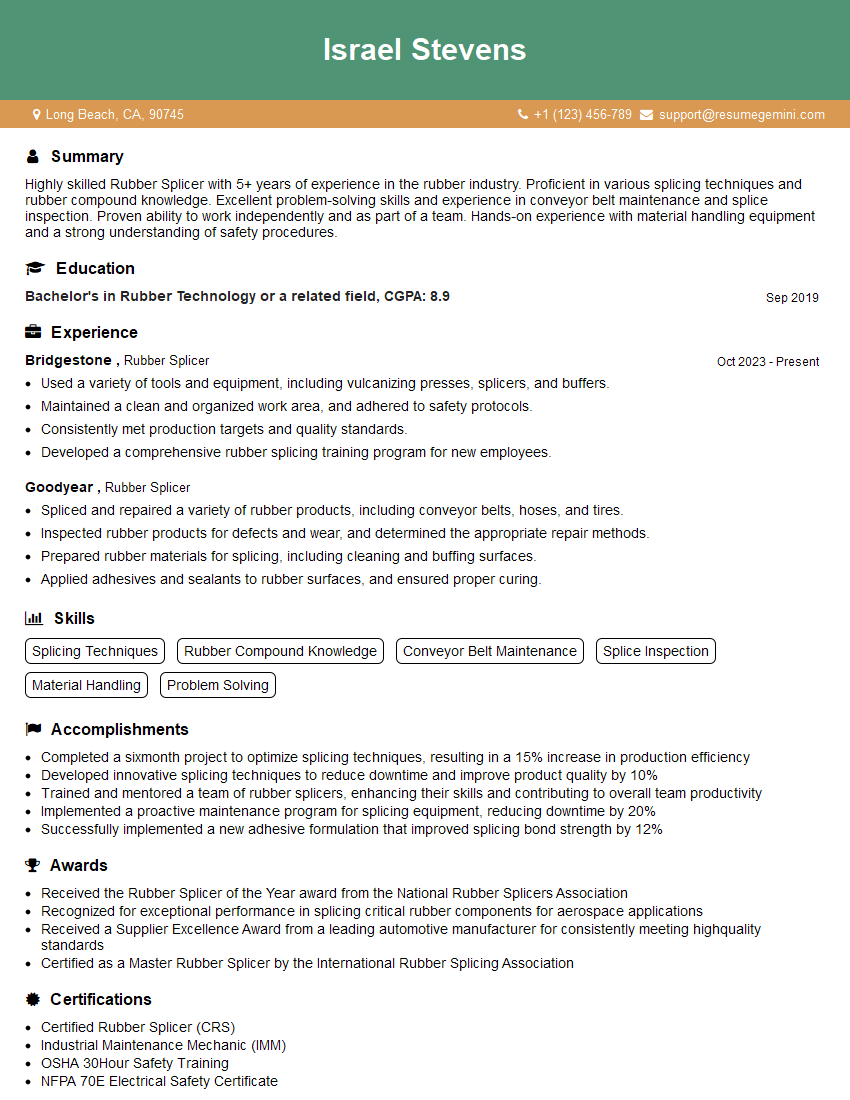

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Splicer

1. What are the different types of rubber splicing techniques?

- Hot splicing

- Cold splicing

- Vulcanization splicing

2. What are the steps involved in hot splicing?

Pre-preparation

- Clean and prepare the rubber surfaces to be spliced

- Apply a splicing solution to the surfaces

Splicing

- Heat the surfaces to the appropriate temperature

- Press the surfaces together and hold them in place until they cool and bond

Post-processing

- Inspect the splice for defects

- Apply a protective coating to the splice

3. What are the advantages and disadvantages of hot splicing?

- Advantages:

- Strong and durable bond

- Can be used to splice different types of rubber

- Disadvantages:

- Requires specialized equipment

- Can be time-consuming

4. What are the steps involved in cold splicing?

- Clean and prepare the rubber surfaces to be spliced

- Apply a cold splicing adhesive to the surfaces

- Press the surfaces together and hold them in place until the adhesive cures

5. What are the advantages and disadvantages of cold splicing?

- Advantages:

- Does not require specialized equipment

- Faster than hot splicing

- Disadvantages:

- Not as strong as hot splicing

- Cannot be used to splice all types of rubber

6. What are the steps involved in vulcanization splicing?

- Clean and prepare the rubber surfaces to be spliced

- Apply a vulcanizing agent to the surfaces

- Heat the surfaces to the appropriate temperature and pressure

- Hold the surfaces in place until they vulcanize and bond

7. What are the advantages and disadvantages of vulcanization splicing?

- Advantages:

- Strong and durable bond

- Can be used to splice different types of rubber

- Disadvantages:

- Requires specialized equipment

- Can be time-consuming

8. What are the different types of rubber splicing machines?

- Hot splicing machines

- Cold splicing machines

- Vulcanization splicing machines

9. What are the factors to consider when selecting a rubber splicing machine?

- The type of rubber being spliced

- The thickness of the rubber

- The desired strength of the splice

- The budget

10. What are the safety precautions that should be taken when splicing rubber?

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator

- Work in a well-ventilated area

- Follow the manufacturer’s instructions for the splicing machine

- Never leave the splicing machine unattended

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Splicers are skilled technicians responsible for joining and repairing rubber components in various industries. The primary objective of this role is to ensure seamless operations by maintaining the integrity of rubber seals, gaskets, and other components.

1. Splicing and Repairing Rubber Components

Rubber Splicers are highly adept at splicing and repairing rubber conveyor belts, hoses, gaskets, and other products using specialized techniques and equipment. They follow precise instructions to achieve optimal results.

2. Equipment Operation and Maintenance

Proficient in operating and maintaining a range of equipment used in splicing and repair processes, including vulcanizing presses, joining machines, and buffing equipment. They ensure equipment is calibrated and functioning correctly.

3. Quality Control and Testing

Rubber Splicers conduct thorough inspections and testing on repaired components to verify their integrity and adherence to specifications. They perform visual examinations, pressure tests, and other quality control measures.

4. Safety Compliance and Housekeeping

Uphold all safety regulations and maintain a clean and organized work environment. They wear appropriate personal protective equipment, observe protocols for hazardous materials handling, and ensure compliance with industry standards.

Interview Tips

1. Research the Company and Industry

Thoroughly research the company’s history, products/services, and industry trends. This knowledge will enable you to engage in meaningful discussions and demonstrate your genuine interest in the role.

2. Highlight Relevant Skills and Experience

Focus on showcasing your skills in rubber splicing, equipment operation, and quality control. Quantify your accomplishments whenever possible using specific examples to demonstrate your impact.

3. Prepare for Technical Questions

Expect questions related to splicing techniques, equipment maintenance, and industry standards. Review technical concepts and prepare clear and concise answers that demonstrate your expertise.

4. Emphasize Safety and Quality

Rubber Splicers play a critical role in ensuring safety and quality within manufacturing processes. Highlight your commitment to following safety protocols and maintaining high-quality standards.

5. Practice Common Interview Questions

Become familiar with common interview questions and prepare thoughtful responses that showcase your qualifications and enthusiasm for the role. Conduct mock interviews to refine your communication skills and build confidence.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rubber Splicer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rubber Splicer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.