Feeling lost in a sea of interview questions? Landed that dream interview for Rubber Cutting Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rubber Cutting Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

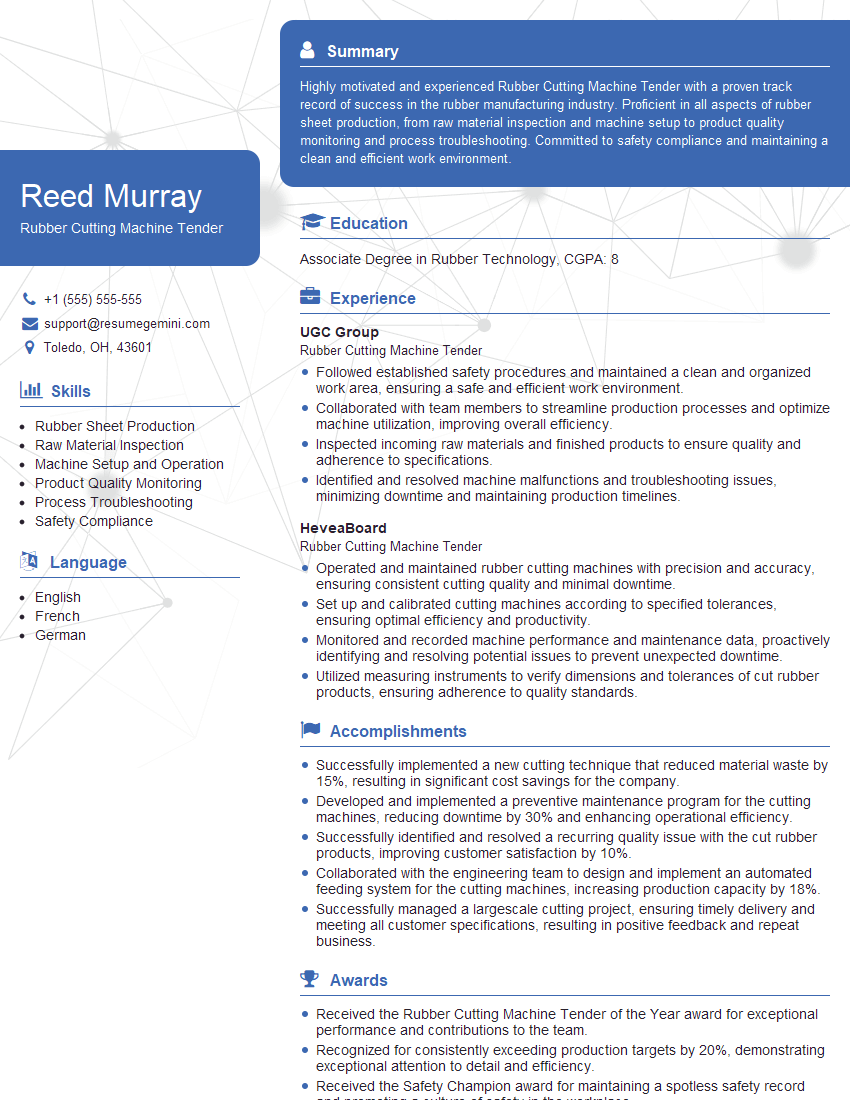

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Cutting Machine Tender

1. What are the key components and functions of a rubber cutting machine?

The key components of a rubber cutting machine are:

- The cutting blade

- The cutting table

- The cutting head

- The conveyor belt

The cutting blade is responsible for cutting the rubber. The cutting table supports the rubber while it is being cut. The cutting head moves the cutting blade across the rubber. The conveyor belt transports the cut rubber away from the cutting area.

2. How do you maintain a rubber cutting machine?

To maintain a rubber cutting machine, you need to:

- Clean the machine regularly

- Lubricate the machine regularly

- Inspect the machine for wear and tear

- Replace worn or damaged parts

Cleaning the machine removes any rubber dust or debris that may have accumulated on the machine. Lubricating the machine ensures that the machine operates smoothly. Inspecting the machine for wear and tear allows you to identify and replace any worn or damaged parts before they cause a problem.

3. What are the safety procedures for operating a rubber cutting machine?

To operate a rubber cutting machine safely, you need to:

- Wear appropriate safety gear

- Follow the manufacturer’s instructions

- Be aware of the machine’s hazards

- Keep the work area clean and free of debris

Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs, can help to protect you from injury. Following the manufacturer’s instructions can help you to operate the machine safely and efficiently. Being aware of the machine’s hazards can help you to avoid accidents. Keeping the work area clean and free of debris can help to prevent slips and falls.

4. What are the different types of rubber cutting machines?

There are many different types of rubber cutting machines, including:

- Manual rubber cutting machines

- Semi-automatic rubber cutting machines

- Automatic rubber cutting machines

- CNC rubber cutting machines

Manual rubber cutting machines are operated by hand. Semi-automatic rubber cutting machines are operated by hand, but they have some automated features. Automatic rubber cutting machines are fully automated. CNC rubber cutting machines are computer-controlled.

5. What are the advantages and disadvantages of using a rubber cutting machine?

Advantages

- Increased productivity

- Improved accuracy and precision

- Reduced labor costs

- Improved safety

Disadvantages

- High initial cost

- Requires skilled operators

- Can be complex to operate

- Requires regular maintenance

Rubber cutting machines can offer a number of advantages, including increased productivity, improved accuracy and precision, reduced labor costs, and improved safety. However, they can also be expensive to purchase and require skilled operators to operate.

6. What is the best way to troubleshoot a rubber cutting machine?

To troubleshoot a rubber cutting machine, you need to:

- Identify the problem

- Check the machine’s settings

- Inspect the machine for damage

- Clean the machine

- Replace any worn or damaged parts

Once you have identified the problem, you can check the machine’s settings to see if they are correct. You should also inspect the machine for any damage. If you find any damage, you should contact a qualified technician to repair the machine. You should also clean the machine regularly to prevent the accumulation of rubber dust and debris.

7. What are some tips for using a rubber cutting machine safely?

To use a rubber cutting machine safely, you should:

- Wear appropriate safety gear

- Follow the manufacturer’s instructions

- Be aware of the machine’s hazards

- Keep the work area clean and free of debris

- Never operate the machine while under the influence of alcohol or drugs

Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs, can help to protect you from injury. Following the manufacturer’s instructions can help you to operate the machine safely and efficiently. Being aware of the machine’s hazards can help you to avoid accidents. Keeping the work area clean and free of debris can help to prevent slips and falls. Never operating the machine while under the influence of alcohol or drugs can help to ensure that you are alert and focused while operating the machine.

8. What are some of the common problems that can occur with rubber cutting machines?

Some of the common problems that can occur with rubber cutting machines include:

- The machine is not cutting the rubber properly

- The machine is making too much noise

- The machine is vibrating excessively

- The machine is leaking oil or hydraulic fluid

If you experience any of these problems, you should contact a qualified technician to repair the machine.

9. What is the difference between a rubber cutting machine and a rubber slitting machine?

A rubber cutting machine is used to cut rubber into different shapes and sizes. A rubber slitting machine is used to cut rubber into long, thin strips.

10. What are the different types of rubber that can be cut with a rubber cutting machine?

A rubber cutting machine can be used to cut a variety of different types of rubber, including:

- Natural rubber

- Synthetic rubber

- Reclaimed rubber

The type of rubber that you can cut with a rubber cutting machine will depend on the specific machine that you are using.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Cutting Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Cutting Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Cutting Machine Tenders are responsible for operating and maintaining rubber cutting machines. Their duties largely revolve around rubber processing in factories. They ensure smooth functioning of the machines and cut rubber into specific dimensions, which ultimately goes into the manufacturing of various rubber products. This role requires technical expertise and strong attention to detail, as even minor mistakes can significantly impact the quality of the final products. Key job responsibilities of a Rubber Cutting Machine Tender include:1. Machine Operation and Maintenance

Rubber Cutting Machine Tenders are primarily responsible for operating and maintaining rubber cutting machines. They are expected to be well-versed with the technical aspects of the machine, including its controls, settings, and safety features. They need to follow established operating procedures and make necessary adjustments to ensure efficient cutting operations. Regular maintenance and cleaning of the machine are also their responsibility to keep it in optimal condition.

2. Rubber Preparation and Cutting

Before cutting rubber, Rubber Cutting Machine Tenders prepare it by removing any impurities or foreign objects. They then feed the rubber into the cutting machine and set the appropriate cutting parameters, such as blade speed, feed rate, and cutting depth. They monitor the cutting process to ensure the rubber is cut accurately and consistently according to the specified dimensions.

3. Quality Control and Inspection

Rubber Cutting Machine Tenders are responsible for maintaining the quality of the cut rubber. They visually inspect the cut pieces to identify any defects or inconsistencies. They also measure the dimensions of the cut pieces to ensure they meet the required specifications. Any defective pieces are removed, and the machine settings are adjusted accordingly to prevent further errors.

4. Production Monitoring and Reporting

Rubber Cutting Machine Tenders monitor the production process closely, ensuring the machine is running smoothly and meeting the desired output. They keep track of the number of pieces cut, the cutting speed, and any downtime experienced. They may also be required to maintain production records and report any issues or inefficiencies to their supervisors.

Interview Tips

To ace an interview for a Rubber Cutting Machine Tender position, candidates should prepare themselves thoroughly. Here are some tips to help them succeed:1. Research the Company and Position

Before the interview, candidates should research the company they are applying to and the specific position they are seeking. This demonstrates their interest in the opportunity and shows that they have put in the effort to learn about the organization. They should familiarize themselves with the company’s products, services, and industry standing. Understanding the company’s culture and values is also beneficial.

2. Highlight Relevant Skills and Experience

Candidates should highlight their relevant skills and experience that align with the job responsibilities of a Rubber Cutting Machine Tender. They should emphasize their technical abilities, such as machine operation, maintenance, and quality control. Any previous experience in the rubber industry or with cutting machines is a valuable asset. They should also demonstrate their attention to detail and ability to work independently.

3. Prepare for Common Interview Questions

Candidates should anticipate common interview questions and prepare their responses in advance. Some frequently asked questions include:

- Tell me about your experience operating rubber cutting machines.

- How do you ensure the accuracy and quality of cut rubber pieces?

- Describe your approach to troubleshooting and resolving machine issues.

- How do you maintain a safe working environment around the cutting machine?

- What are your strengths and weaknesses as a Rubber Cutting Machine Tender?

4. Practice Your Answers

Practicing interview answers helps candidates deliver their responses confidently and clearly. They can practice in front of a mirror, with a friend or family member, or record themselves and review their performance. Practicing allows them to refine their answers, eliminate filler words, and maintain a professional demeanor.

5. Dress Professionally and Arrive Punctually

First impressions matter, so candidates should dress professionally for the interview. They should arrive at the interview location on time, demonstrating respect for the interviewer’s time. Punctuality and a polished appearance convey a positive and responsible attitude.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rubber Cutting Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.