Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tube Cutter Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tube Cutter Operator so you can tailor your answers to impress potential employers.

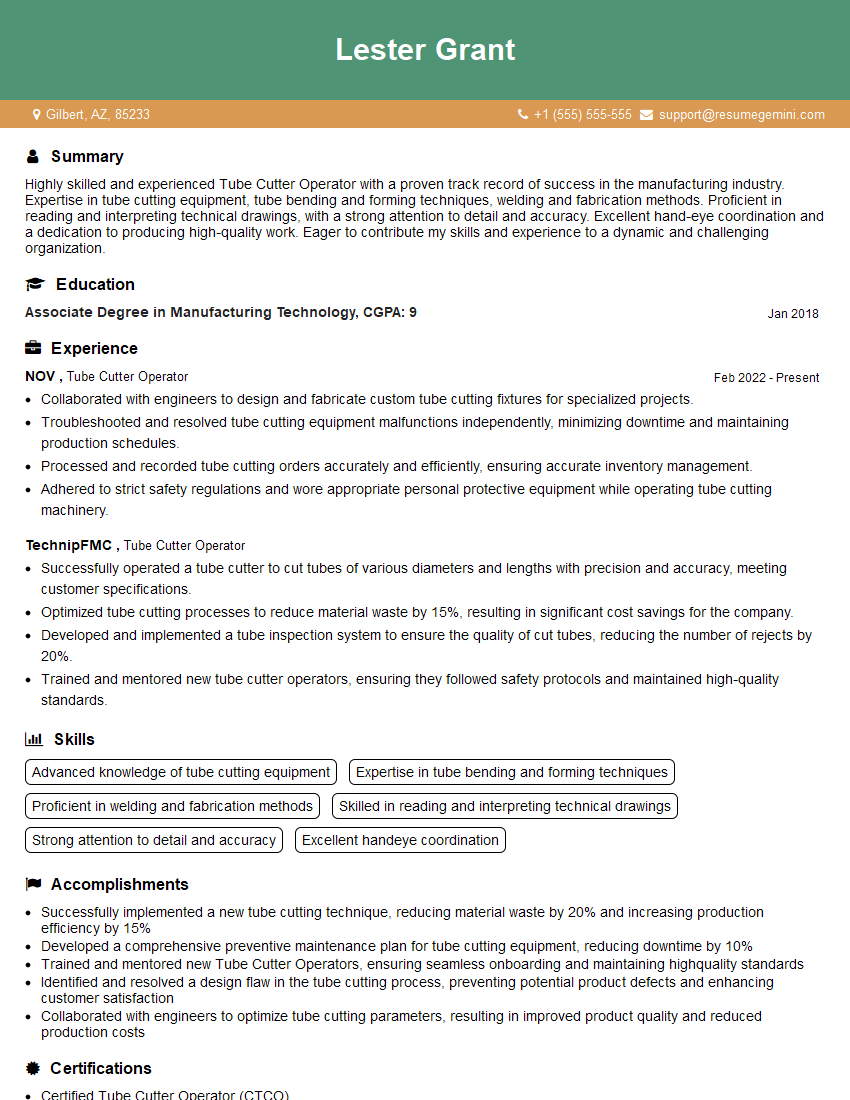

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Cutter Operator

1. What are the primary responsibilities of a Tube Cutter Operator?

As a Tube Cutter Operator, my key responsibilities typically include:

- Operating and maintaining tube cutting machines to cut tubes to precise specifications.

- Inspecting and measuring tubes to ensure they meet quality standards.

- Setting up and adjusting cutting parameters, such as speed, feed rate, and blade type.

2. Describe the different types of tube cutting machines you have experience with.

CNC Tube Cutters

- Programmable machines that use computer-controlled axes to precisely cut tubes.

- Capable of cutting complex shapes and angles with high accuracy.

Manual Tube Cutters

- Operated manually to cut tubes using a rotating blade.

- Require skilled operators to achieve accurate cuts.

Band Saws

- Use a continuous band with teeth to cut through tubes.

- Capable of making curved cuts and cutting a variety of materials.

3. How do you ensure the accuracy and precision of tube cuts?

I employ several techniques to ensure accuracy and precision:

- Calibrating and maintaining cutting machines regularly.

- Using precision measuring tools, such as calipers and micrometers.

- Following established cutting procedures and adhering to prescribed tolerances.

- Inspecting cut tubes thoroughly before passing them for further processing.

4. What are the safety precautions you observe while operating tube cutting machines?

Safety is paramount, and I adhere to the following precautions:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure that the machine is securely grounded and properly maintained.

- Inspect the cutting area for any potential hazards before starting the machine.

- Keep hands and clothing away from moving parts while the machine is in operation.

- Follow established safety protocols and report any accidents or near misses promptly.

5. How do you handle different types of materials when cutting tubes?

I adjust my approach based on the material:

- Metals: Use appropriate cutting blades and speeds to minimize burrs and ensure a clean cut.

- Plastics: Consider the melting point of the plastic and use a blade that will not melt or deform the material.

- Composites: Use sharp blades to prevent delamination or fraying of the composite material.

6. What is your experience with tube bending?

I am proficient in tube bending using:

- Manual Tube Benders: Capable of bending tubes manually to precise angles.

- CNC Tube Benders: Utilize computer-controlled axes to achieve complex bends with high accuracy.

7. How do you maintain and troubleshoot tube cutting machines?

I perform regular maintenance tasks:

- Lubricating moving parts.

- Replacing worn blades or other components.

For troubleshooting:

- Identify the issue by observing symptoms.

- Consult the machine’s manual or seek assistance from a qualified technician if necessary.

- Repair or replace faulty components.

8. Describe a challenging project you encountered as a Tube Cutter Operator.

One challenging project involved cutting and bending intricate tubes for a medical device.

- Required precise cutting and bending to ensure the device’s functionality.

- Collaborated with design engineers to develop a cutting and bending plan.

- Successfully produced the tubes within the specified tolerances.

9. How do you stay updated on the latest advancements in tube cutting technology?

I stay informed through:

- Attending industry conferences and workshops.

- Reading trade publications and online resources.

- Consulting with equipment manufacturers and suppliers.

10. What factors influence the quality of a tube cut?

Several factors affect cut quality:

- Blade sharpness: Sharp blades produce clean, burr-free cuts.

- Cutting speed: The correct speed minimizes heat buildup and ensures precision.

- Feed rate: An appropriate feed rate prevents excessive force on the blade and material.

- Material type: Different materials require specific cutting parameters.

- Machine accuracy: Well-maintained and calibrated machines deliver consistent cuts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Cutter Operators are responsible for operating tube cutting machines to cut tubes to specified lengths and shapes. They ensure that the tubes are cut accurately and efficiently, and that the machines are properly maintained.

1. Operate tube cutting machines

Tube Cutter Operators must be able to operate a variety of tube cutting machines, including manual, semi-automatic, and automatic machines. They must be able to set up the machines correctly, and to adjust the settings to achieve the desired cut.

- Set up and operate tube cutting machines

- Adjust machine settings to achieve desired cut

2. Inspect and measure tubes

Tube Cutter Operators must be able to inspect and measure tubes to ensure that they meet specifications. They must be able to identify defects, and to make adjustments to the cutting process to correct them.

- Inspect tubes for defects

- Measure tubes to ensure they meet specifications

3. Maintain tube cutting machines

Tube Cutter Operators must be able to maintain tube cutting machines to ensure that they are operating safely and efficiently. They must be able to identify potential problems, and to make repairs as needed.

- Lubricate and clean tube cutting machines

- Identify and repair potential problems

4. Follow safety procedures

Tube Cutter Operators must be able to follow safety procedures to protect themselves and others from injury. They must be aware of the hazards associated with their work, and must take steps to avoid them.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

Interview Tips

To ace the interview for a Tube Cutter Operator position, it is important to be prepared. Here are some tips to help you prepare:

1. Research the company and position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you to tailor your answers to the specific requirements of the position.

- Visit the company’s website

- Read the job description carefully

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

- Prepare a brief answer to each question

- Practice your answers out loud

3. Be prepared to talk about your experience

The interviewer will likely want to know about your experience as a Tube Cutter Operator. Be prepared to discuss your skills and experience in detail, and to provide examples of your work. It is also helpful to bring a portfolio of your work to the interview.

- Highlight your skills and experience

- Provide examples of your work

4. Be professional and enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during the interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer. It is also important to show your enthusiasm for the position and the company.

- Dress appropriately

- Arrive on time

- Be polite and respectful

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tube Cutter Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.