Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tube Skiver position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

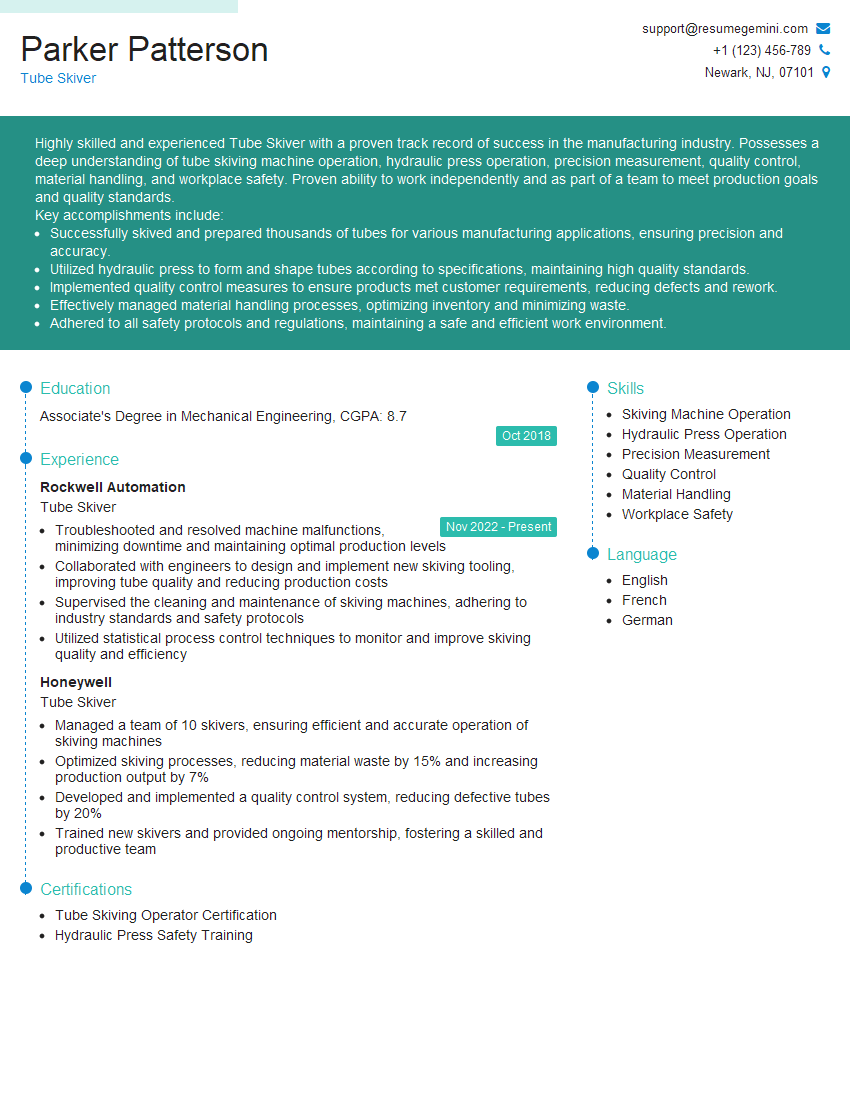

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Skiver

1. What are the different types of tube skiving machines?

There are two main types of tube skiving machines: manual and automatic. Manual machines are operated by hand, while automatic machines are powered by a motor. Automatic machines are more efficient and can produce higher quality skives than manual machines.

2. What are the key features to look for when choosing a tube skiving machine?

Accuracy

- The accuracy of a tube skiving machine is determined by the precision of its cutting tool and the stability of its frame.

- A high-quality machine will be able to produce skives with a high degree of accuracy, which is essential for applications such as tube welding.

Speed

- The speed of a tube skiving machine is determined by the power of its motor and the efficiency of its cutting tool.

- A high-speed machine will be able to produce skives quickly and efficiently, which can save time and money.

Versatility

- The versatility of a tube skiving machine is determined by its ability to handle different types and sizes of tubes.

- A versatile machine will be able to handle a wide range of applications, which can save you the time and expense of purchasing multiple machines.

3. What are the different types of cutting tools used in tube skiving machines?

There are two main types of cutting tools used in tube skiving machines: single-point and multi-point tools.

Single-point tools

- Single-point tools are made of a single piece of high-speed steel.

- They are used for light-duty applications and can produce a high degree of accuracy.

Multi-point tools

- Multi-point tools are made of multiple pieces of high-speed steel.

- They are used for heavy-duty applications and can produce a high volume of skives.

4. What are the different types of skives that can be produced by tube skiving machines?

There are three main types of skives that can be produced by tube skiving machines:

Straight skives

- Straight skives are the most common type of skive.

- They are used for applications such as tube welding and tube bending.

Tapered skives

- Tapered skives are used for applications such as tube flaring and tube reducing.

- They can be produced with a variety of angles and tapers.

Necked skives

- Necked skives are used for applications such as tube threading and tube grooving.

- They have a reduced diameter at the end of the skive, which makes them ideal for fitting into tight spaces.

5. What are the safety precautions that should be taken when operating a tube skiving machine?

- Always wear safety glasses and gloves when operating a tube skiving machine.

- Never touch the cutting tool or the workpiece while the machine is running.

- Keep the machine clean and free of debris.

- Follow all manufacturer’s instructions for safe operation.

6. What are the maintenance procedures that should be performed on a tube skiving machine?

- Regularly clean the machine and remove any debris.

- Lubricate the moving parts of the machine according to the manufacturer’s instructions.

- Inspect the cutting tool for wear and tear and replace it if necessary.

- Follow all manufacturer’s instructions for maintenance.

7. How do you troubleshoot a tube skiving machine?

If you are having problems with a tube skiving machine, there are a few things you can do to troubleshoot the issue:

- Check the power supply to the machine.

- Check the cutting tool for wear and tear.

- Check the workpiece for any defects.

- Check the machine’s settings.

- If you cannot troubleshoot the issue yourself, contact the manufacturer for assistance.

8. What are the applications for tube skiving machines?

Tube skiving machines are used in a variety of applications, including:

- Tube welding

- Tube bending

- Tube flaring

- Tube reducing

- Tube threading

- Tube grooving

9. What are the benefits of using a tube skiving machine?

There are many benefits to using a tube skiving machine, including:

- Increased accuracy and precision

- Improved efficiency and productivity

- Reduced labor costs

- Improved safety

10. What are the challenges of using a tube skiving machine?

There are a few challenges that can be associated with using a tube skiving machine, including:

- High cost of the machine

- Complexity of the machine

- Need for skilled operators

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Skiver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Skiver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Skiving is a critical process in the manufacturing industry that involves shaving or cutting thin layers from the inner diameter of a cylindrical tube. The key responsibilities of a Tube Skiver include:

1. Pre-Inspection and Setup

Inspecting the tube for any defects or imperfections.

- Preparing and setting up the skiving machine according to the specified dimensions and tolerances.

- Ensuring that the machine is properly calibrated and maintained.

2. Skiving Operation

Skiving the tube to the desired thickness, removing the thin layer of material.

- Monitoring the skiving process to ensure precision and accuracy.

- Adjusting the machine settings as needed to maintain proper thickness and surface finish.

3. Post-Inspection and Quality Control

Inspecting the skived tube to verify that it meets the required specifications and quality standards.

- Measuring and recording the thickness and other dimensions.

- Identifying and correcting any defects or imperfections.

4. Maintenance and Troubleshooting

Performing regular maintenance on the skiving machine to ensure smooth operation.

- Calibrating and adjusting the machine as needed.

- Troubleshooting and resolving any technical issues that may arise.

Interview Tips

To ace the interview for a Tube Skiver position, consider the following tips and preparation strategies:

1. Research the Company and Position

Learn about the company’s products, services, and industry reputation. Understand the specific requirements and responsibilities of the Tube Skiver role within the organization.

- Visit the company’s website and social media pages.

- Read industry news and articles to demonstrate your knowledge of the field.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications. Practice answering these questions clearly and concisely, highlighting your relevant abilities.

- “Tell me about your experience in tube skiving and the techniques you use.”

- “Describe a situation where you faced a challenge in tube skiving and how you overcame it.”

3. Showcase Your Technical Skills

Emphasize your technical skills and knowledge in tube skiving, including machine operation, measurement techniques, and quality control procedures. Provide specific examples to demonstrate your proficiency.

- “I have experience operating various tube skiving machines, including CNC and manual models.”

- “I am proficient in using calipers, micrometers, and other measuring tools to ensure precision in skiving operations.”

4. Highlight Your Quality Control Experience

Stress the importance of quality control in tube skiving. Explain your understanding of quality standards, inspection techniques, and corrective actions to ensure the highest quality products.

- “I am committed to maintaining high quality standards in my work, ensuring that all skived tubes meet the required specifications.”

- “I have a strong understanding of ISO 9001 quality management principles and apply them in my daily operations.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tube Skiver interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.