Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Air Bag Curer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

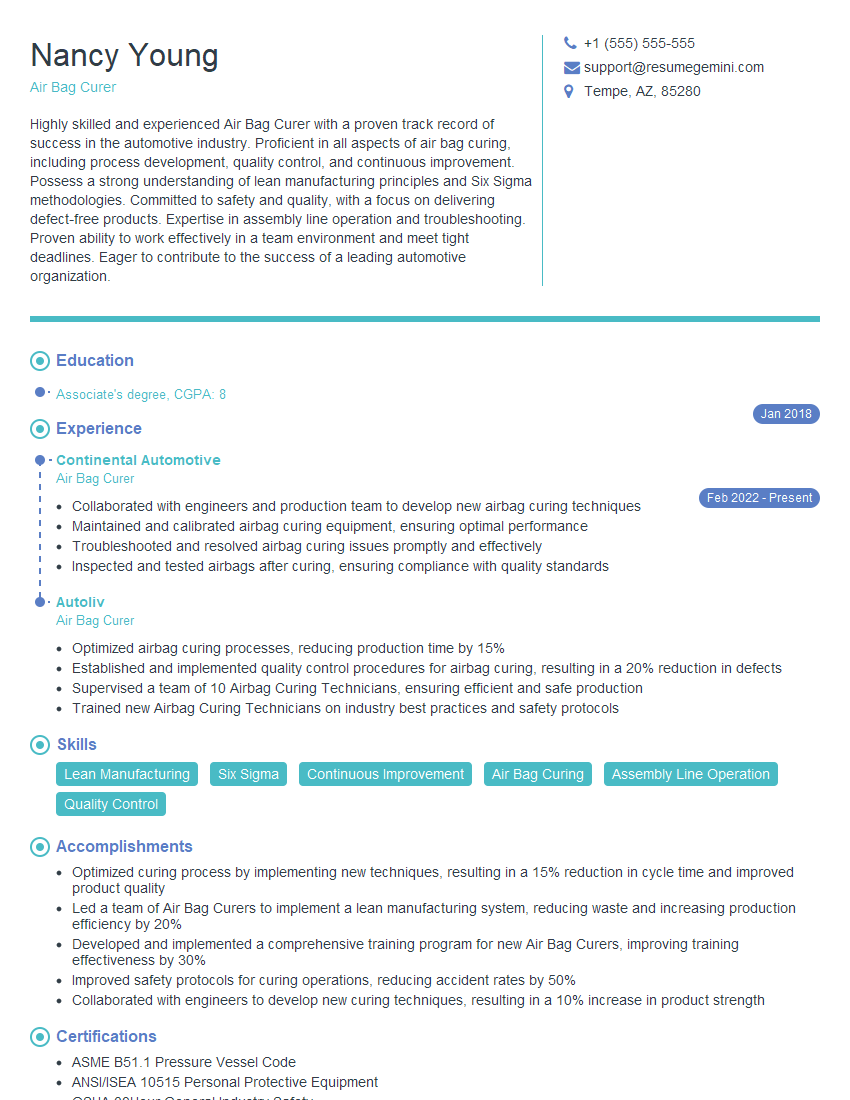

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Air Bag Curer

1. Explain the process of curing an airbag inflator propellant and how you ensure the quality of the cured propellant?

- The curing process involves heating the propellant to a specific temperature and holding it at that temperature for a specific time.

- During curing, the propellant undergoes a chemical reaction that converts it from a liquid to a solid.

- The quality of the cured propellant is critical to the performance of the airbag inflator.

- To ensure the quality of the cured propellant, we use a variety of techniques, including:

- Visual inspection

- Chemical analysis

- Physical testing

2. How do you troubleshoot a curing oven?

Troubleshooting an Airbag Curing Oven

- Check the power supply to the oven.

- Check the temperature controller.

- Check the heating elements.

- Check the airflow through the oven.

- Check the insulation around the oven.

Additional Troubleshooting Tips

- If the oven is not heating up, check the heating elements and the temperature controller.

- If the oven is not maintaining the correct temperature, check the insulation around the oven.

- If the oven is not curing the propellant properly, check the airflow through the oven.

3. What are the safety precautions that you need to take when working with airbag inflators?

- Airbag inflators are explosive devices, so it is important to take the following safety precautions when working with them:

- Always wear safety glasses and gloves.

- Do not smoke or eat in the area where you are working with airbag inflators.

- Keep airbag inflators away from heat and open flames.

- Do not drop or puncture airbag inflators.

- If an airbag inflator deploys, immediately leave the area and call 911.

4. What is the difference between a single-stage and a dual-stage airbag inflator?

- A single-stage airbag inflator uses a single propellant to generate the gas that inflates the airbag.

- A dual-stage airbag inflator uses two propellants to generate the gas that inflates the airbag.

- The first propellant is a fast-burning propellant that generates a large amount of gas quickly.

- The second propellant is a slow-burning propellant that generates a smaller amount of gas over a longer period of time.

- The dual-stage design helps to reduce the risk of injury to the occupants of the vehicle in the event of a crash.

5. What are the different types of airbag inflator propellants?

- There are three main types of airbag inflator propellants:

- Sodium azide

- Potassium nitrate

- Nitroguanidine

- Each type of propellant has its own unique properties and advantages.

- Sodium azide is the most common type of airbag inflator propellant.

- It is a highly reactive compound that generates a large amount of gas quickly.

- Potassium nitrate is a less reactive compound than sodium azide, but it is also less powerful.

- Nitroguanidine is a relatively new type of airbag inflator propellant.

- It is a very stable compound that generates a large amount of gas over a long period of time.

6. What are the factors that affect the performance of an airbag inflator?

- The performance of an airbag inflator is affected by a number of factors, including:

- The type of propellant used

- The amount of propellant used

- The size and shape of the airbag

- The temperature of the airbag

- The humidity of the airbag

- It is important to consider all of these factors when designing and manufacturing airbag inflators.

7. What are the regulations that govern the manufacture of airbag inflators?

- The manufacture of airbag inflators is governed by a number of regulations, including:

- The Federal Motor Vehicle Safety Standards (FMVSS)

- The National Highway Traffic Safety Administration (NHTSA)

- The International Organization for Standardization (ISO)

- These regulations ensure that airbag inflators are manufactured to a high standard of quality and safety.

8. What are the latest trends in airbag inflator technology?

- The latest trends in airbag inflator technology include:

- The development of new propellants that are more powerful and less toxic

- The use of new materials for airbag inflators that are lighter and more durable

- The development of new designs for airbag inflators that are more efficient and effective

- These trends are helping to improve the safety and performance of airbags.

9. What is the future of airbag inflator technology?

- The future of airbag inflator technology is bright.

- Researchers are developing new propellants, materials, and designs that will make airbags even safer and more effective.

- In the future, airbags may be able to do more than just protect occupants in the event of a crash.

- They may also be able to sense and react to other dangerous situations, such as rollovers and side impacts.

10. How do you stay up-to-date on the latest airbag inflator technology?

- I stay up-to-date on the latest airbag inflator technology by reading industry publications, attending conferences, and networking with other professionals in the field.

- I am also involved in a number of research and development projects that are focused on improving the safety and performance of airbags.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Air Bag Curer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Air Bag Curer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Air Bag Curer is a manufacturing professional responsible for the operation and maintenance of airbag curing equipment. They collaborate closely with a team of production supervisors and quality control inspectors to ensure the production of high-quality airbags.

1. Equipment Operation

Plays a crucial role in operating curing equipment, including autoclaves, ovens, and presses, to ensure proper curing of airbag components.

- Monitors the equipment parameters, such as temperature, pressure, and time, to achieve optimal curing results.

- Performs regular maintenance and calibration of the equipment to prevent malfunctions and ensure accuracy.

2. Quality Control

Inspects the cured airbag components to ensure they meet the required specifications and safety standards.

- Conducts quality checks, such as dimensional measurements, visual inspections, and performance testing, to identify any defects or deviations.

- Maintains detailed records of quality control data to track and analyze trends.

3. Process Improvement

Actively participates in process improvement initiatives to optimize curing processes and reduce production costs.

- Collaborates with engineers and supervisors to identify potential areas for improvement.

- Conducts experiments and tests to develop and implement process modifications.

4. Safety Compliance

Adheres to all safety protocols and regulations related to the operation of airbag curing equipment and handling of hazardous materials.

- Wears appropriate personal protective equipment and follows established safety procedures.

- Maintains a clean and organized work area to minimize potential hazards.

Interview Tips

Preparing thoroughly for an Air Bag Curer interview is crucial to showcase your skills and expertise. Here are a few tips to help you stand out:

1. Research the Company and Role

Familiarize yourself with the company’s mission, products, and industry reputation. Understand the specific responsibilities and requirements of the Air Bag Curer role.

- Visit the company’s website, read industry publications, and connect with current or former employees on LinkedIn.

- Thoroughly review the job description to identify the key skills and experience required.

2. Highlight Your Expertise

Quantify your accomplishments and provide specific examples of your experience in operating curing equipment, conducting quality control inspections, and contributing to process improvements.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Emphasize the positive impact your work has had on production efficiency, quality, and cost reduction.

3. Demonstrate Safety Awareness

Air Bag Curer positions require a strong focus on safety. Highlight your understanding of safety protocols, hazardous material handling, and emergency procedures.

- Share examples of how you have implemented safety measures in previous roles.

- Explain your commitment to maintaining a safe work environment and adhering to industry regulations.

4. Ask Thoughtful Questions

Asking insightful questions demonstrates your interest in the role and the company. Prepare a list of questions that explore the following:

- Company culture and values

- Advancement opportunities and professional development

- Company’s commitment to safety and environmental sustainability

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Air Bag Curer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!