Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bowling Ball Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

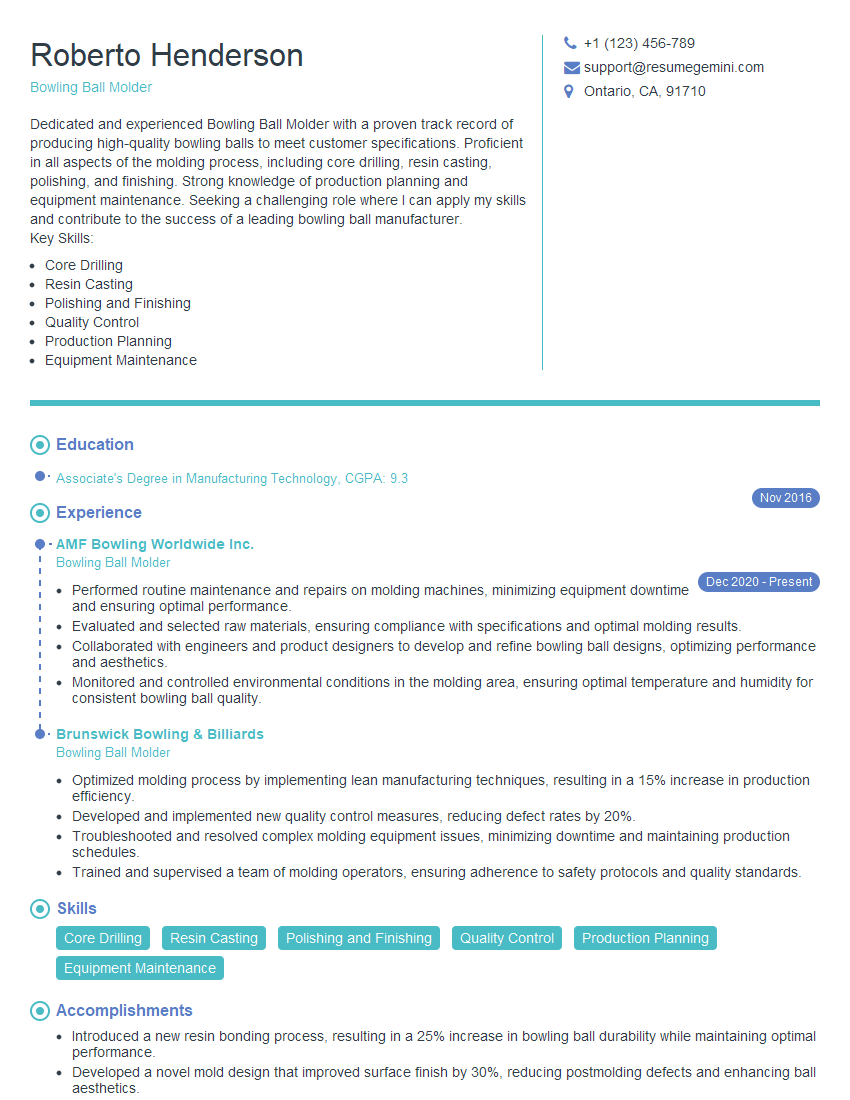

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bowling Ball Molder

1. What is the role of a bowling ball molder?

A bowling ball molder is responsible for creating bowling balls by shaping and curing the material. They must have a strong understanding of the molding process and be able to operate the machinery safely and efficiently.

2. What are the different types of bowling balls?

There are three main types of bowling balls: plastic, urethane, and reactive resin. Plastic balls are the most common and are made of a durable plastic material. Urethane balls are made of a softer material that provides more hook and control. Reactive resin balls are made of a very soft material that provides the most hook and control.

3. What is the process of molding a bowling ball?

The process of molding a bowling ball begins with preparing the mold. The mold is then filled with a liquid resin material, which is then heated and cured. Once the resin has cured, the ball is removed from the mold and sanded and polished.

4. What are the different types of molds used to make bowling balls?

There are two main types of molds used to make bowling balls: two-piece molds and three-piece molds. Two-piece molds consist of a top and bottom half that are clamped together to form the mold cavity. Three-piece molds consist of a top half, a bottom half, and a core insert that is placed in the center of the mold cavity.

5. What are the different types of materials used to make bowling balls?

The three main types of materials used to make bowling balls are plastic, urethane, and reactive resin. Plastic balls are made of a durable plastic material. Urethane balls are made of a softer material that provides more hook and control. Reactive resin balls are made of a very soft material that provides the most hook and control.

6. What are the different factors that affect the performance of a bowling ball?

The performance of a bowling ball is affected by a number of factors, including the type of ball, the weight of the ball, the hardness of the ball, and the surface texture of the ball.

7. What are the different types of bowling ball surfaces?

There are three main types of bowling ball surfaces: matte, polished, and sanded. Matte surfaces provide the most control, polished surfaces provide the most hook, and sanded surfaces provide a balance of control and hook.

8. What is the difference between a symmetrical and an asymmetrical bowling ball?

Symmetrical bowling balls have a weight distribution that is evenly distributed around the center of the ball. Asymmetrical bowling balls have a weight distribution that is not evenly distributed around the center of the ball.

9. What are the different types of bowling ball cores?

There are two main types of bowling ball cores: pancake cores and symmetric cores. Pancake cores are flat, while symmetric cores are round.

10. What are the different types of bowling ball covers?

There are three main types of bowling ball covers: plastic covers, urethane covers, and reactive resin covers. Plastic covers are the most durable, urethane covers provide more hook and control, and reactive resin covers provide the most hook and control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bowling Ball Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bowling Ball Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bowling Ball Molders play a crucial role in the manufacturing of bowling balls by operating machinery that molds and shapes the balls to their final specifications. Their responsibilities encompass various aspects of the production process.

1. Molding Process

Operate molding machines to create the core and cover of bowling balls.

- Position and secure the mold components correctly.

- Monitor and adjust machine settings to ensure proper temperature and pressure.

- Pour molten plastic into the molds and initiate the molding cycle.

- Inspect molded balls for defects and quality.

2. Core Preparation

Prepare and assemble the bowling ball’s core, which provides weight and balance.

- Cut, shape, and assemble the core components to meet specifications.

- Insert the core into the mold before pouring the cover plastic.

- Ensure the core is properly centered and balanced within the mold.

3. Finishing and Inspection

Perform finishing operations on molded balls to achieve the desired surface and weight.

- Grind, sand, and polish the balls to remove imperfections and achieve a smooth surface.

- Drill finger holes according to customer specifications.

- Inspect finished balls for quality and compliance with standards.

- Package and prepare balls for shipment.

4. Machine Maintenance

Maintain and troubleshoot molding machines and related equipment to ensure optimal performance.

- Perform regular cleaning, lubrication, and adjustments on machinery.

- Identify and diagnose malfunctions promptly.

- Follow safety protocols and maintain a clean and organized work area.

Interview Tips

To ace an interview for a Bowling Ball Molder position, it is essential to be well-prepared. Here are some tips to help you make a strong impression during the interview process:

1. Research the Company and Industry

Familiarize yourself with the bowling ball manufacturing industry and the specific company you’re applying to. Visit their website, read news articles, and learn about their products and market position.

- Example: You could mention that you understand the importance of precision and quality in the bowling ball manufacturing industry, and that you have been following the recent innovations in bowling ball design.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly applicable to the role. Focus on your ability to operate molding machines, prepare bowling ball cores, and perform finishing operations.

- Example: You could describe your experience in setting up and operating molding machines, including your ability to troubleshoot common issues and maintain optimal performance.

3. Showcase Your Attention to Detail

Bowling Ball Molders need to have a keen eye for detail to ensure the accuracy and quality of their work. In the interview, highlight your ability to inspect molded balls for defects and ensure they meet specifications.

- Example: You could talk about your experience in using precision measuring tools and your ability to identify even the smallest deviations from the desired shape or weight.

4. Emphasize Your Teamwork and Safety Consciousness

Bowling Ball Molders often work in a team environment and must adhere to strict safety protocols. Show the interviewer that you are a team player who is committed to following safety guidelines.

- Example: You could mention your experience working in a team environment, and your understanding of the importance of following safety regulations to ensure the well-being of yourself and your colleagues.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the role and the company. This shows the interviewer that you are engaged and genuinely interested in the opportunity.

- Example: You could ask about the company’s plans for future product development or their commitment to sustainability in the manufacturing process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bowling Ball Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.