Feeling lost in a sea of interview questions? Landed that dream interview for Cinder Block Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cinder Block Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

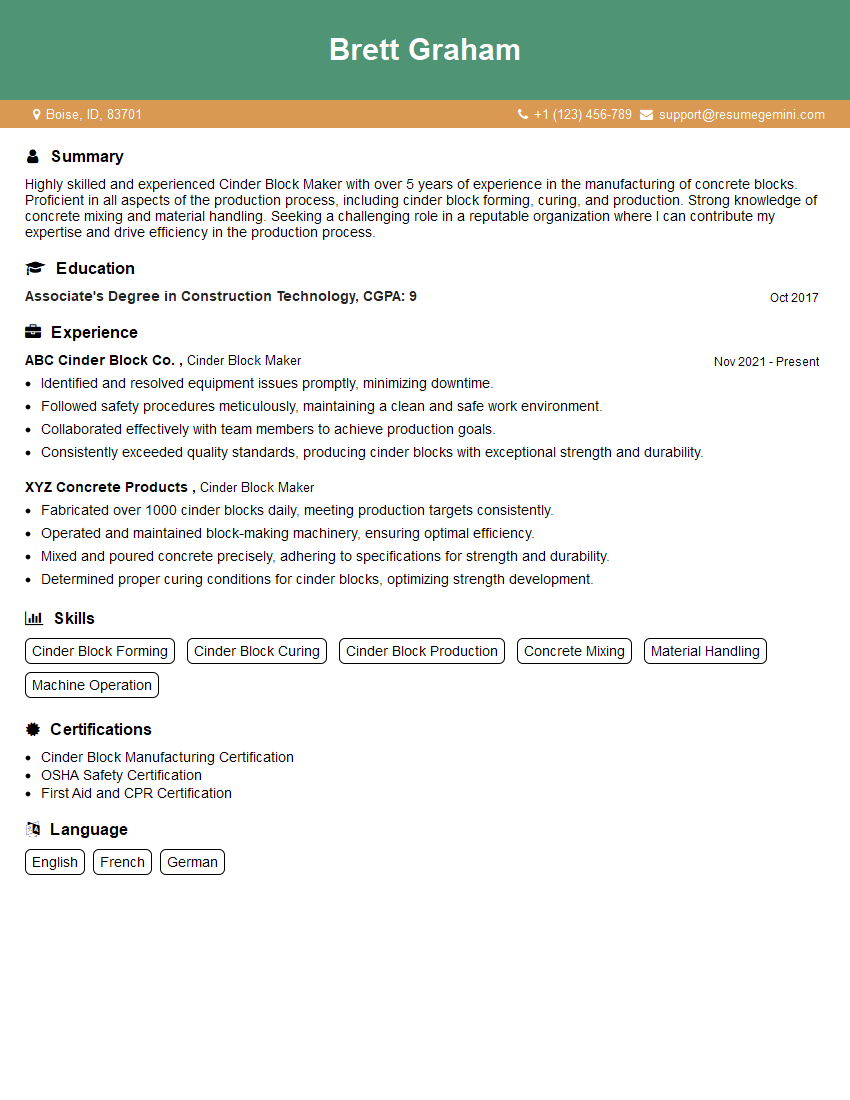

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cinder Block Maker

1. How do you ensure the quality of cinder blocks you produce?

Quality control is of utmost importance in this industry. We are very careful during the block making process, from procuring the quality of raw materials to curing and storing the blocks.

- First, our raw materials such as cement, aggregate, and water are checked and tested before using them for production.

- Secondly, all the ingredients must be mixed in a correct ratio and mixed properly. The flowability of the materials is measured as per the mold design and required strength.

- After pouring the mixture into the molds, care is taken to compact it properly to get rid of any voids. Curing is a very important process, and the time period may vary depending on the ambient temperature.

- Finally, the blocks are tested and inspected before sending them to the storage area.

2. What are the common problems faced during the production of cinder blocks? How do you address them?

Issues with the raw materials:

- The cement should be checked for lumps, which can affect the strength of the blocks.

- The aggregate should be free from dust and impurities, which can reduce the block’s quality.

- The water used should be clean and free of contaminants, as it can affect the setting time of the cement.

Issues with the production process:

- The concrete mix should be properly mixed and compacted to avoid voids in the blocks.

- The blocks should be cured properly to achieve the desired strength.

- The blocks should be handled carefully to avoid damage.

3. How do you calculate the production capacity of a cinder block making machine?

The production capacity of a cinder block making machine is dependent on several factors such as:

- The type of machine being used

- The size of the blocks being produced

- The speed of the machine

- The efficiency of the operator

To calculate the production capacity, we need to consider all these factors and use the following formula:

Production capacity = (Number of blocks produced per cycle) x (Number of cycles per hour) x (Number of hours of operation)

4. How do you maintain and troubleshoot a cinder block making machine?

Regular maintenance is important to keep the cinder block making machine in good working condition and to prevent breakdowns. Some of the maintenance tasks that need to be performed include:

- Cleaning the machine regularly to remove dust and debris

- Lubricating the moving parts of the machine

- Inspecting the machine for any signs of wear and tear

- Replacing worn-out parts as needed

- Calibrating the machine regularly to ensure that it is producing blocks of the correct size and quality

In case of a breakdown, it is important to troubleshoot the problem quickly and efficiently to minimize downtime. Some of the common problems that can occur with cinder block making machines include:

- The machine not starting

- The machine not producing blocks

- The blocks being produced are not the correct size or quality

By following the manufacturer’s instructions and using proper troubleshooting techniques, most problems with cinder block making machines can be resolved quickly and easily.

5. What are the safety precautions that need to be taken when operating a cinder block making machine?

- Always wear appropriate safety gear, including safety glasses, gloves, and a hard hat.

- Never operate the machine if you are not properly trained.

- Keep the work area clean and free of debris.

- Be aware of the location of all controls and emergency stops.

- Never reach into the machine while it is operating.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for safe operation.

6. What are the different types of cinder blocks available?

- Solid cinder blocks: These are the most common type of cinder blocks and are made from a mixture of cement, sand, and cinders.

- Hollow cinder blocks: These blocks have hollow cores, which make them lighter and more insulating than solid cinder blocks.

- Lightweight cinder blocks: These blocks are made from a mixture of cement, sand, and lightweight aggregates, such as pumice or perlite.

- Heavyweight cinder blocks: These blocks are made from a mixture of cement, sand, and heavy aggregates, such as iron ore or steel slag.

7. What are the advantages and disadvantages of using cinder blocks for construction?

Advantages:

- Cinder blocks are strong and durable.

- They are fire-resistant.

- They are relatively inexpensive.

- They are easy to work with.

Disadvantages:

- Cinder blocks are heavy.

- They can be difficult to cut and shape.

- They can absorb moisture, which can lead to mold and mildew.

8. What are the different applications of cinder blocks?

- Cinder blocks can be used for a variety of applications, including:

- Foundation walls

- Load-bearing walls

- Non-load-bearing walls

- Fences

- Patios

- Driveways

9. What are the latest trends in the cinder block industry?

- One of the latest trends in the cinder block industry is the use of recycled materials in the production of cinder blocks.

- This is a more sustainable and environmentally friendly way to produce cinder blocks, and it can also help to reduce the cost of production.

- Another trend is the use of new technologies to improve the quality and efficiency of cinder block production.

- For example, some manufacturers are now using automated machines to produce cinder blocks, which can help to reduce the cost of production and improve the quality of the finished product.

10. What are the challenges facing the cinder block industry?

- One of the challenges facing the cinder block industry is the competition from other building materials, such as concrete blocks and bricks.

- Cinder blocks are also facing competition from new, more sustainable building materials, such as recycled plastic and bamboo.

- Another challenge facing the cinder block industry is the rising cost of raw materials, such as cement and sand.

- This is making it more difficult for cinder block manufacturers to produce cinder blocks at a competitive price.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cinder Block Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cinder Block Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cinder Block Makers are responsible for the production of cinder blocks, which are used in construction. Their key job responsibilities include:

1. Operating Cinder Block Making Machine

Cinder Block Makers are responsible for operating and maintaining the cinder block making machine. This involves setting up the machine, loading the raw materials, and monitoring the production process.

- Loading the raw materials into the machine

- Setting up the machine according to the desired block size and shape

- Monitoring the production process to ensure that the blocks are being produced according to specifications

2. Inspecting Cinder Blocks

Cinder Block Makers are also responsible for inspecting the cinder blocks to ensure that they meet quality standards. This involves checking the blocks for cracks, chips, or other defects.

- Visually inspecting the blocks for cracks, chips, or other defects

- Measuring the blocks to ensure that they meet the desired size and shape

- Testing the blocks to ensure that they meet the desired strength and durability

3. Stacking and Storing Cinder Blocks

Cinder Block Makers are responsible for stacking and storing the cinder blocks. This involves stacking the blocks in a safe and orderly manner, and protecting them from the elements.

- Stacking the blocks in a safe and orderly manner

- Protecting the blocks from the elements by covering them with tarps or plastic wrap

- Keeping track of the inventory of cinder blocks

4. Cleaning and Maintaining Equipment

Cinder Block Makers are also responsible for cleaning and maintaining the equipment. This involves cleaning the machine, replacing worn parts, and performing other maintenance tasks.

- Cleaning the machine on a regular basis

- Replacing worn parts as needed

- Performing other maintenance tasks to keep the equipment in good working order

Interview Tips

To ace the interview for a Cinder Block Maker position, candidates should be prepared to discuss their experience in operating and maintaining cinder block making machines, inspecting cinder blocks, and stacking and storing cinder blocks. They should also be prepared to discuss their knowledge of safety procedures and their ability to work in a team environment.

1. Preparation is Key

The first step to acing the interview is to prepare. This means researching the company, the position, and the industry. Candidates should also practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Research the company’s website and social media pages

- Read articles and news stories about the industry

- Practice answering common interview questions

2. Dress Professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing casual clothes, such as jeans or t-shirts

3. Be Punctual

Punctuality is important for any interview, but it is especially important for a Cinder Block Maker position. This shows the interviewer that you are reliable and respectful of their time.

- Plan your route to the interview in advance

- Give yourself plenty of time to get to the interview

- If you are running late, call the interviewer to let them know

4. Be Yourself

It is important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be honest and genuine, and let your personality shine through.

- Answer questions honestly and openly

- Be yourself and let your personality shine through

- Don’t try to be someone you’re not

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cinder Block Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.