Are you gearing up for a career in Concrete Block Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Concrete Block Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

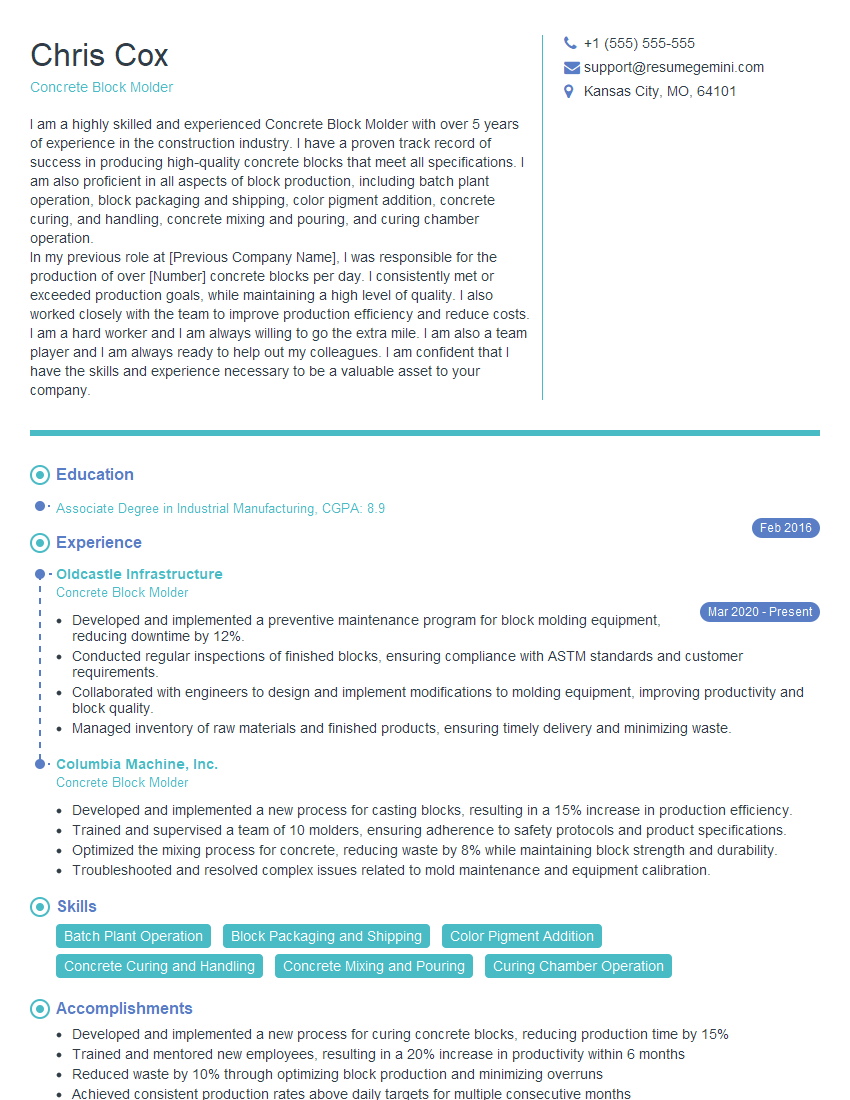

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Block Molder

1. What are the different types of concrete blocks that can be produced using a concrete block molder?

- Solid concrete blocks

- Hollow concrete blocks

- Pavement concrete blocks

- Architectural concrete blocks

2. What are the key factors that determine the quality of concrete blocks?

Raw materials

- Quality of cement

- Type and size of aggregate

- Water content

Production process

- Mixing and proportioning

- Molding and compaction

- Curing

3. How do you troubleshoot common problems encountered during concrete block production?

- Block cracking

- Block efflorescence

- Block shrinkage

- Block color variation

4. What are the safety precautions that must be followed when operating a concrete block molder?

- Wear appropriate personal protective equipment (PPE)

- Inspect the machine before each use

- Follow manufacturer’s operating instructions

- Be aware of potential hazards (e.g., moving parts, electrical equipment)

5. How can you improve the efficiency of concrete block production?

- Optimize the production process

- Use high-quality raw materials

- Maintain the machine regularly

- Train operators properly

6. Describe the process of mixing and proportioning concrete for block production.

- Measure and weigh ingredients according to specified mix design

- Charge ingredients into mixer

- Mix ingredients until they are thoroughly combined

- Adjust water content as needed to achieve desired consistency

7. Explain the difference between face-mix and through-mix concrete blocks.

- Face-mix blocks: Only the surface layer of the block is colored or textured

- Through-mix blocks: Color and/or texture is consistent throughout the entire block

8. What are the benefits of using automated concrete block molding machines?

- Increased production efficiency

- Improved product quality

- Reduced labor costs

- Enhanced safety

9. How do you calibrate a concrete block molder to ensure accurate block dimensions?

- Measure the dimensions of a sample block

- Compare measured dimensions to specified tolerances

- Adjust mold settings as needed

- Repeat steps until desired accuracy is achieved

10. Describe the different types of concrete block curing methods.

- Water curing: Blocks are submerged in water or sprayed with water

- Steam curing: Blocks are exposed to steam in a closed chamber

- Moist curing: Blocks are covered with plastic sheeting or other materials to retain moisture

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Block Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Block Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Block Molders are responsible for the production of concrete blocks used in construction. They operate machines that mold and shape the concrete mixture into blocks, ensuring that they meet quality standards and specifications.

1. Setting up and operating molding machines

Molders set up and operate molding machines that shape the concrete mixture into blocks. They ensure that the machines are calibrated and functioning properly to produce blocks that meet the required shape, size, and strength specifications.

- Loading the concrete mixture into the mold

- Adjusting the machine settings to control the block’s shape and size

2. Monitoring and maintaining molding equipment

Molders monitor the molding equipment to ensure that it is operating smoothly and efficiently. They perform routine maintenance tasks, such as cleaning, lubricating, and adjusting the machines, to prevent breakdowns and ensure optimal performance.

- Checking for worn or damaged parts

- Making minor repairs and adjustments

3. Inspecting and stacking concrete blocks

Molders inspect the concrete blocks to ensure that they meet the required specifications and quality standards. They check for defects, such as cracks, voids, or uneven surfaces, and remove any defective blocks.

- Visually inspecting the blocks for visible defects

- Measuring the blocks to ensure that they meet the required size specifications

- Stacking the blocks for storage or shipment

4. Maintaining a clean and safe work environment

Molders maintain a clean and safe work environment by following safety protocols and housekeeping procedures. They regularly clean the molding machines and work area to prevent accidents and ensure the safety of themselves and others.

- Cleaning up spills and debris

- Storing materials properly

- Following safety guidelines and wearing appropriate safety gear

Interview Tips

To ace an interview for a Concrete Block Molder position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some tips and hacks to help candidates prepare effectively:

1. Research the company and industry

Candidates should research the company they are applying to and the concrete block industry to gain insights into the company’s culture, products, and market position. This knowledge will help them tailor their answers to the interviewer’s questions and demonstrate their interest in the role.

- Visiting the company’s website and social media pages

- Reading industry publications and news articles

2. Review the job description and qualifications

Candidates should carefully review the job description and qualifications to identify the key responsibilities and skills required for the role. They should then highlight their relevant experience and skills during the interview, providing specific examples to demonstrate how they meet the requirements.

- Highlighting relevant skills, such as machine operation, quality control, and safety

- Providing examples of their ability to work in a team and meet production targets

3. Practice common interview questions

Candidates should practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practicing these questions will help them become more comfortable and confident during the actual interview.

- Preparing a brief and engaging introduction about their skills and experience

- Developing specific examples to showcase their strengths and weaknesses

4. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of the interview shows that candidates are engaged and interested in the role. Candidates should prepare questions about the company, the industry, and the specific responsibilities of the Concrete Block Molder position.

- Inquiring about the company’s growth plans and industry trends

- Asking about the specific challenges and opportunities associated with the role

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Block Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!