Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Floorperson interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Floorperson so you can tailor your answers to impress potential employers.

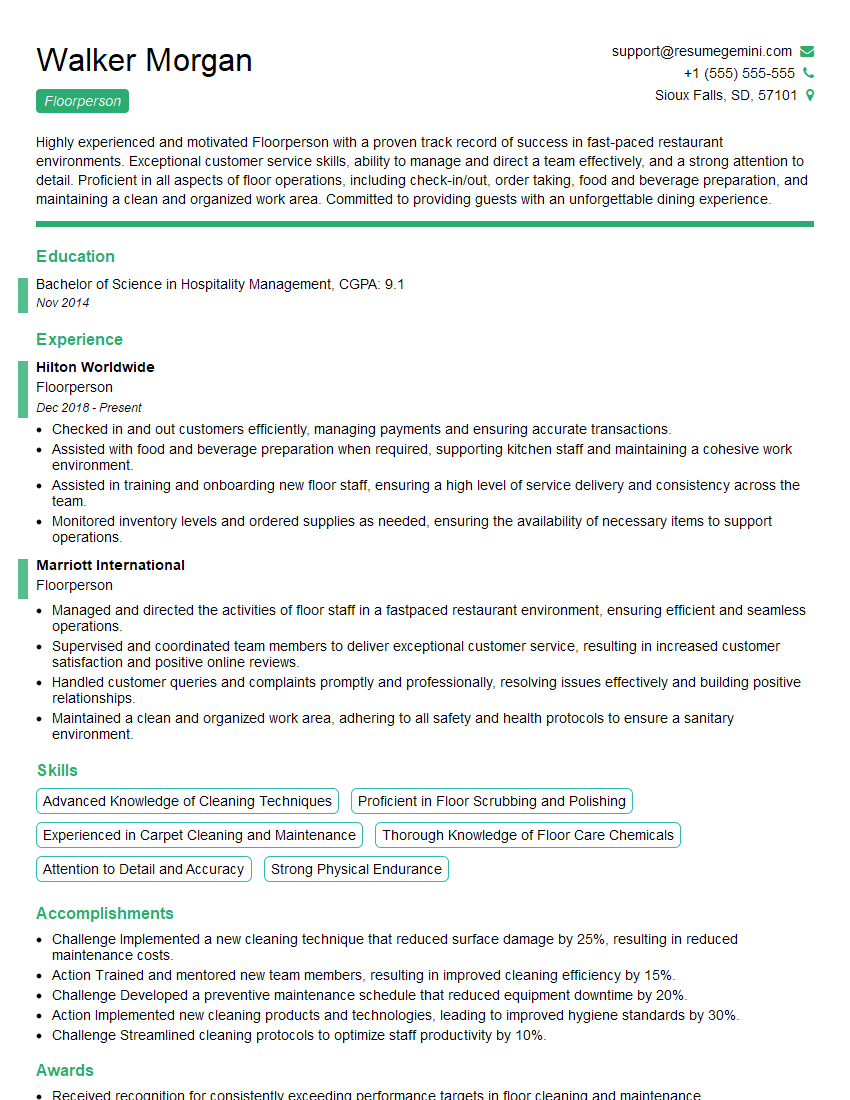

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floorperson

1. What are the primary responsibilities of a Floorperson in a production environment?

- Maintaining a clean and safe work area

- Loading and unloading materials from machines

- Operating simple machines and equipment

- Inspecting products for quality

- Assisting with inventory control

2. Describe your experience in operating automated machinery and equipment.

Experience with specific machines

- Name of machine 1

- Name of machine 2

Responsibilities involving automated machinery

- Loading and unloading materials

- Monitoring machine performance

- Troubleshooting basic issues

3. How do you ensure the quality of products on the production line?

- Visual inspection for defects

- Using measuring tools to check dimensions

- Testing products for functionality

- Following established quality control procedures

4. What is your understanding of lean manufacturing principles?

- Eliminating waste and inefficiencies

- Continuous improvement (Kaizen)

- Just-in-time production

- Empowering employees

5. How do you handle working in a fast-paced and demanding production environment?

- Maintaining focus and concentration

- Prioritizing tasks effectively

- Adapting to changing demands

- Working well under pressure

6. What is your experience with working in a team environment on the production floor?

- Communicating effectively with team members

- Collaborating on tasks

- Providing support and assistance

- Working towards common goals

7. Describe a situation where you identified and resolved a problem on the production line.

- Identifying the problem and its root cause

- Developing and implementing a solution

- Verifying the effectiveness of the solution

8. What are some of the safety protocols and procedures that you are familiar with in a production environment?

- Proper use of personal protective equipment

- Following established safety procedures

- Identifying and reporting potential hazards

- Responding to emergency situations

9. How do you stay updated with the latest advancements in manufacturing technology?

- Attending industry conferences and workshops

- Reading industry publications and online resources

- Consulting with experts in the field

10. Why are you interested in working as a Floorperson in our company?

- Interest in the company’s products or industry

- Alignment with the company’s values and culture

- Career growth opportunities

- Opportunity to contribute to the team’s success

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floorperson.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floorperson‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Floorperson, you will play a pivotal role in maintaining the smooth operation of our production floor. Your responsibilities will include:

1. Monitoring and Inspecting Production Processes

Keep a watchful eye on production processes to ensure they are running efficiently and in accordance with established standards. Conduct regular inspections to identify and address any potential issues, such as equipment malfunctions or quality control deviations.

- Consistently monitor production lines for any deviations from standard operating procedures.

- Inspect finished products for quality defects, ensuring they meet the company’s specifications.

2. Operating and Maintaining Production Equipment

Operate a variety of production equipment, including machinery, tools, and conveyors. Perform routine maintenance tasks, such as cleaning, lubricating, and adjusting equipment, to ensure optimal performance and prevent breakdowns.

- Safely operate production equipment according to established protocols.

- Conduct preventive maintenance, such as cleaning and lubricating machinery, to extend its lifespan.

3. Material Handling and Storage

Ensure the efficient movement of materials throughout the production floor. Load, unload, and transport materials using forklifts or other equipment. Maintain inventory levels, ensuring a steady supply of materials for production.

- Load and unload raw materials, finished goods, and other items using forklifts or manual handling techniques.

- Maintain accurate inventory records and communicate any discrepancies to management.

4. Quality Control and Process Improvement

Actively participate in quality control measures to ensure the production of high-quality products. Identify and resolve quality issues, implementing corrective actions as needed. Collaborate with the quality control team to identify areas for process improvement and enhance efficiency.

- Conduct in-process inspections and document any non-conformances.

- Contribute to continuous improvement initiatives by suggesting process modifications and efficiency enhancements.

5. Health and Safety Compliance

Prioritize health and safety in the workplace. Adhere to all established safety protocols, including wearing appropriate personal protective equipment (PPE) and following proper handling procedures. Report any potential hazards or unsafe conditions to management.

- Maintain a clean and organized work area to prevent accidents and injuries.

- Report any safety concerns or incidents to supervisors immediately.

Interview Tips

To ace your interview for a Floorperson position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the industry. Visit their website, read industry publications, and prepare questions that show you have taken the time to learn about their operations and market position.

- Tailor your answers to the company’s specific needs and values.

- Ask insightful questions about the company’s production processes, quality standards, and safety protocols.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating production equipment, handling materials, and maintaining a clean and organized work environment. Quantify your achievements and provide specific examples of how you have contributed to the efficiency and quality of production processes in previous roles.

- Use numbers to demonstrate your productivity and attention to detail.

- Describe your experience in troubleshooting equipment malfunctions and resolving quality issues.

3. Showcase Your Safety Awareness and Compliance

Convey your strong commitment to safety and your understanding of industry regulations. Explain how you have consistently maintained a safe work environment and followed established safety protocols. Share examples of your involvement in safety training or initiatives, such as hazard identification or accident prevention programs.

- Emphasize your understanding of PPE requirements and your ability to work safely in a production environment.

- Describe your experience in conducting risk assessments and implementing corrective actions to mitigate potential hazards.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your qualifications. Practice answering questions related to your experience in production operations, quality control, and safety compliance. Consider preparing examples of your problem-solving abilities and your commitment to teamwork and continuous improvement.

- Practice answering questions about your strengths and weaknesses.

- Prepare questions to ask the interviewer, which demonstrates your interest in the role and the company.

5. Dress Professionally and Maintain a Positive Attitude

Present yourself professionally and maintain a positive attitude throughout the interview. Dress appropriately, arrive on time, and make eye contact with the interviewer. Be enthusiastic about the opportunity and convey your eagerness to contribute to the team’s success.

- First impressions matter, so make sure you make a good one.

- Enthusiasm and a positive attitude can make a big difference.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Floorperson interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.