Are you gearing up for an interview for a Curing Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Curing Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

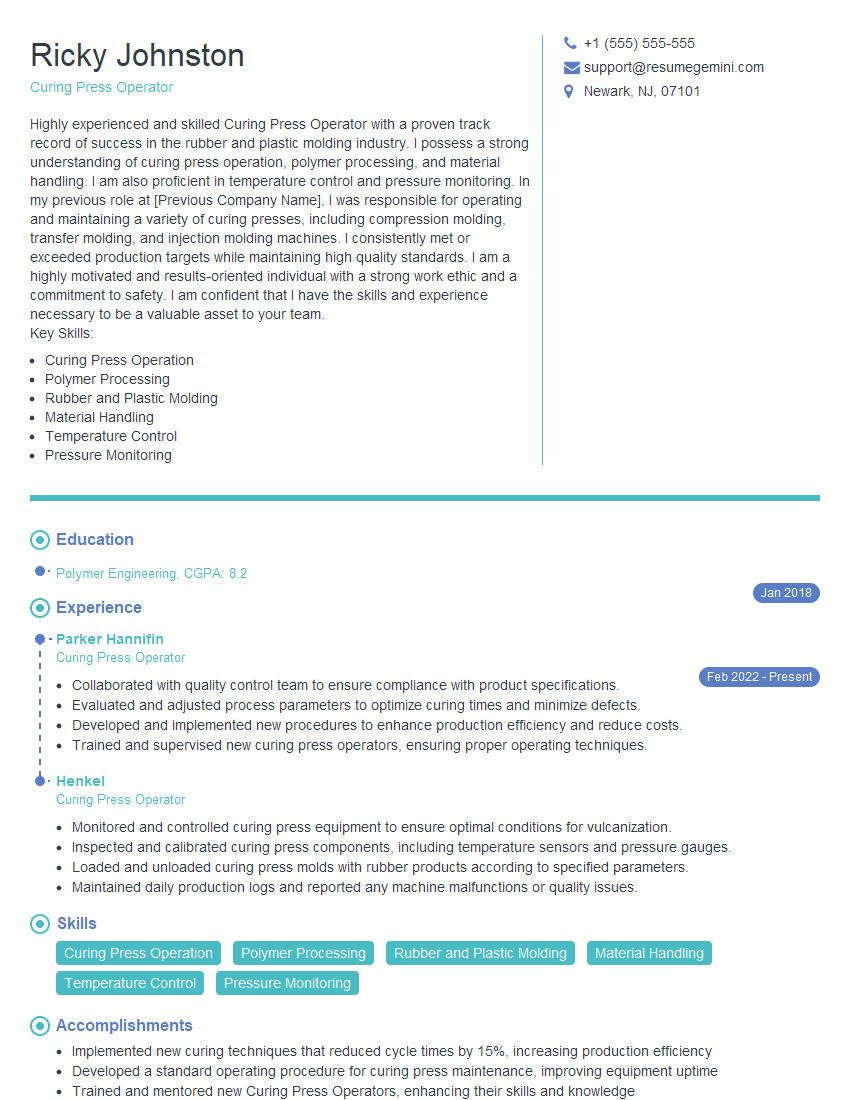

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Curing Press Operator

1. Describe the role of a Curing Press Operator?

- The Curing Press Operator is responsible for the operation of curing presses in a high-volume manufacturing environment.

- The operator must be able to identify and correct errors in the curing process, maintain a clean and organized work area, and adhere to all safety regulations.

2. What are the different types of curing presses and how do they work?

subheading of the answer

- There are two main types of curing presses: vacuum presses and bladder presses.

- Vacuum presses use a vacuum to pull air out from between the mold and the part, creating a strong bond between the two.

- Bladder presses use a bladder to apply pressure to the part, which forces the resin into the mold and creates a strong bond.

subheading of the answer

- The curing process involves heating the mold and part to a specific temperature for a specified amount of time.

- The heat causes the resin to cure, or harden, and form a strong bond between the mold and the part.

3. What are the safety precautions that must be taken when operating a curing press?

- The operator must wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- The operator must be aware of the location of all emergency shut-off switches and fire extinguishers.

- The operator must never attempt to repair or adjust the press while it is in operation.

4. What are the quality control procedures that must be followed when operating a curing press?

- The operator must inspect the mold and part before each use to ensure that they are clean and free of defects.

- The operator must set the press to the correct temperature and pressure for the type of resin being used.

- The operator must monitor the press throughout the curing process to ensure that the temperature and pressure are maintained at the correct levels.

5. What are the troubleshooting procedures that must be followed when operating a curing press?

- If the press does not heat up to the correct temperature, the operator should check the heating element and the thermostat.

- If the press does not apply the correct pressure, the operator should check the pressure gauge and the hydraulic system.

- If the part is not curing properly, the operator should check the type of resin being used and the curing time.

6. What are the maintenance procedures that must be followed when operating a curing press?

- The operator should clean the press regularly to remove any resin or debris.

- The operator should inspect the press regularly for any signs of wear or damage.

- The operator should lubricate the press regularly according to the manufacturer’s instructions.

7. What are the different types of resins that can be used in a curing press?

- There are many different types of resins that can be used in a curing press, including epoxy resins, polyester resins, and vinyl ester resins.

- The type of resin that is used will depend on the application and the desired properties of the finished product.

8. What are the different types of molds that can be used in a curing press?

- There are many different types of molds that can be used in a curing press, including aluminum molds, silicone molds, and fiberglass molds.

- The type of mold that is used will depend on the application and the desired properties of the finished product.

9. What are the different factors that can affect the curing process?

- The curing process can be affected by a number of factors, including the temperature, the pressure, and the time.

- It is important to control these factors carefully to ensure that the finished product has the desired properties.

10. What are the different applications of curing presses?

- Curing presses are used in a wide variety of applications, including the manufacture of automotive parts, aerospace components, and medical devices.

- Curing presses are also used in the production of fiberglass boats, surfboards, and other composite products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Curing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Curing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Curing Press Operators are responsible for operating curing presses to form and cure rubber products. They work closely with other production team members to ensure that the products meet the required specifications.

1. Operate and maintain curing presses

Curing Press Operators are responsible for operating and maintaining curing presses. This includes setting up the press, loading and unloading the product, and monitoring the curing process. They must also be able to troubleshoot any problems that may arise with the press.

- Set up and operate curing presses according to established procedures.

- Monitor curing process and make adjustments as needed.

- Troubleshoot and repair minor press malfunctions.

2. Inspect and test cured products

Curing Press Operators are also responsible for inspecting and testing cured products. This includes checking the products for defects, such as cracks, bubbles, or other imperfections. They must also be able to test the products to ensure that they meet the required specifications.

- Inspect cured products for defects.

- Test products to ensure they meet specifications.

- Maintain quality control records.

3. Maintain a clean and safe work area

Curing Press Operators must also maintain a clean and safe work area. This includes keeping the press and surrounding area clean and free of debris. They must also follow all safety procedures to prevent accidents.

- Clean and maintain press and surrounding area.

- Follow all safety procedures.

- Report any hazardous conditions.

4. Work as part of a team

Curing Press Operators typically work as part of a team. They must be able to communicate effectively with other team members and follow instructions. They must also be able to work independently and take initiative.

- Work as part of a team.

- Communicate effectively with others.

- Follow instructions and take initiative.

Interview Tips

Preparing for an interview can be daunting, but following these tips can increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you to tailor your answers to the specific requirements of the position.

- Visit the company’s website.

- Read about the company in news articles and industry publications.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and concisely. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for the position you are applying for.

- Arrive for your interview on time, or even a few minutes early.

4. Be yourself and be enthusiastic

It is important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident and proud of your skills and experience. Also, show the interviewer that you are excited about the position and the company. When you are enthusiastic, it is more likely that the interviewer will be enthusiastic about hiring you.

- Be yourself and don’t try to be someone you’re not.

- Be confident and proud of your skills and experience.

- Show the interviewer that you are excited about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Curing Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.