Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dehydrating Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

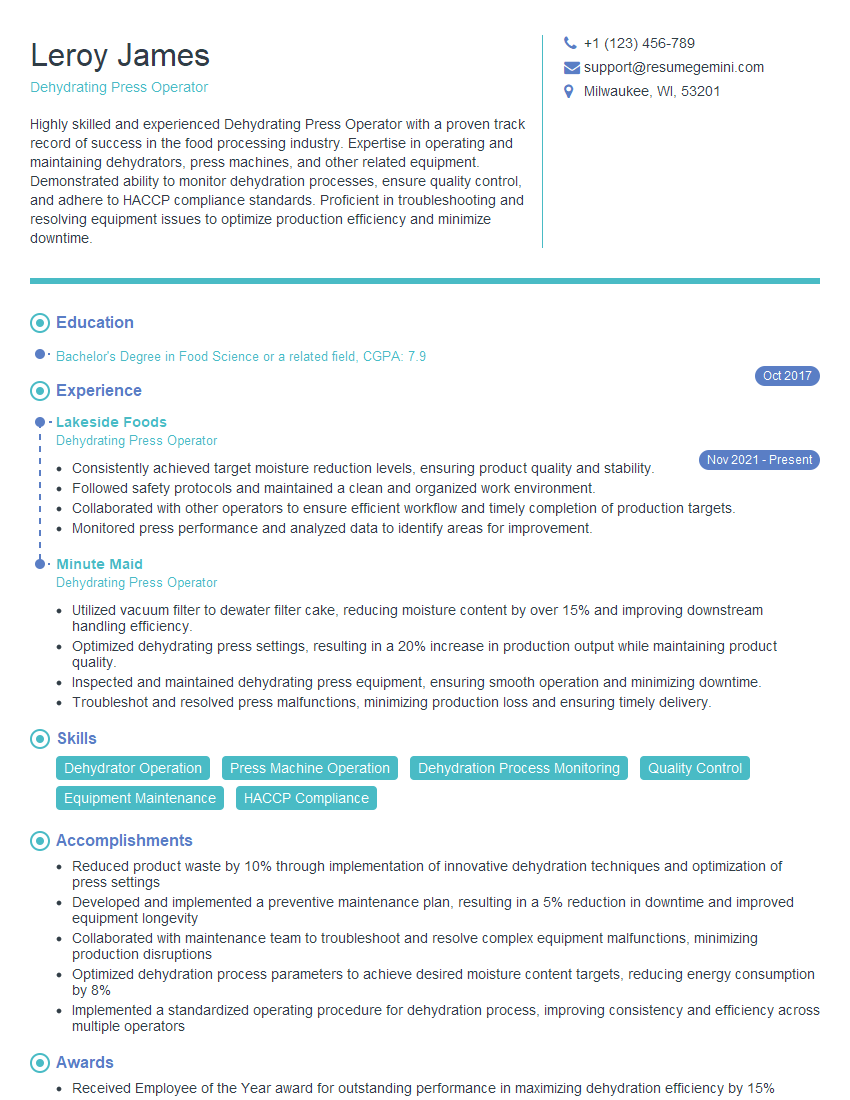

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dehydrating Press Operator

1. Explain the process of operating a dehydrating press?

The process of operating a dehydrating press involves the following steps:

- Preparing the press by cleaning and assembling the press and its components.

- Loading the press with the product to be dehydrated.

- Setting the press parameters, including temperature, pressure, and cycle time.

- Starting the press and monitoring its operation.

- Unloading the press and removing the dehydrated product.

- Cleaning and sanitizing the press and its components.

2. What are the different types of dehydrating presses and their applications?

Mechanical presses

- Use mechanical force to apply pressure to the product.

- Suitable for dehydrating fruits, vegetables, and other food products.

Hydrostatic presses

- Use hydraulic pressure to apply pressure to the product.

- Suitable for dehydrating more delicate products, such as herbs and flowers.

Vacuum presses

- Use a vacuum to remove moisture from the product.

- Suitable for dehydrating heat-sensitive products, such as enzymes and pharmaceuticals.

3. How do you ensure the safety of the equipment and yourself while operating a dehydrating press?

To ensure safety while operating a dehydrating press, it is important to follow these guidelines:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Inspect the press and its components before each use to identify any potential hazards.

- Follow proper operating procedures and avoid overloading the press.

- Keep the work area clean and well-lit.

- Be aware of the location of the emergency stop button and know how to use it.

4. How do you troubleshoot common problems that may occur during the operation of a dehydrating press?

Common problems that may occur during the operation of a dehydrating press include:

- Product not dehydrating properly: Check the temperature, pressure, and cycle time settings. Ensure that the product is properly loaded into the press.

- Press not operating: Check the power supply and electrical connections. Inspect the press for any mechanical issues.

- Leaks: Check the seals and gaskets for damage or wear. Tighten any loose fittings.

5. How do you maintain and calibrate a dehydrating press to ensure its optimal performance?

Regular maintenance and calibration are essential for ensuring the optimal performance of a dehydrating press. Maintenance tasks include:

- Cleaning and lubricating the press and its components.

- Inspecting the press for any wear or damage.

- Calibrating the press to ensure accurate temperature and pressure readings.

6. Can you describe the different drying mechanisms involved in the dehydration process?

The dehydration process involves three main drying mechanisms:

- Evaporation: Moisture from the product evaporates into the surrounding air.

- Sublimation: Moisture from the product directly transforms into vapor without passing through the liquid phase.

- Osmotic drying: Moisture from the product is drawn out by a concentrated solution, such as sugar or salt.

7. How do you determine the optimal drying conditions for a specific product?

The optimal drying conditions for a specific product depend on factors such as:

- Product type and moisture content.

- Desired final moisture content.

- Drying equipment and capacity.

- Environmental conditions.

8. What quality control measures are implemented to ensure the quality of the dehydrated products?

Quality control measures for dehydrated products include:

- Raw material inspection.

- Process monitoring.

- Product testing.

- Packaging and storage.

9. How do you handle and store dehydrated products to maintain their quality and prevent spoilage?

Dehydrated products should be handled and stored properly to maintain their quality and prevent spoilage:

- Store in airtight containers to prevent moisture absorption.

- Keep in a cool, dry place away from direct sunlight.

- Use oxygen absorbers or vacuum packaging to remove excess oxygen.

10. What are the emerging trends and advancements in dehydration technology?

Emerging trends in dehydration technology include:

- Use of microwave and radio frequency drying.

- Development of more energy-efficient drying processes.

- Integration of automation and control systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dehydrating Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dehydrating Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dehydrating Press Operator is primarily responsible for operating and maintaining dehydrating presses in a food processing or manufacturing plant. Their key duties involve ensuring the efficient operation of the press, monitoring the dehydration process, and maintaining a clean and safe work environment.

1. Operating Dehydrating Press

The operator is in charge of setting up, operating and monitoring the dehydrating press. They must ensure that the press is functioning properly and that the dehydration process is running smoothly. This includes setting the correct temperature and pressure, loading and unloading the press, and monitoring the progress of the dehydration.

- Set up and operate dehydrating presses to remove moisture from food products.

- Monitor the dehydration process to ensure that products are dried to the desired moisture content.

2. Maintaining Dehydrating Press

The operator is also responsible for maintaining the dehydrating press. They must perform regular cleaning, lubrication, and repairs to keep the press in good working condition. They should also inspect the press for any potential problems and take corrective action as needed.

- Clean and lubricate dehydrating presses to ensure they are in good working condition.

- Perform minor repairs and adjustments to the press.

3. Ensuring Product Quality

The operator is responsible for ensuring that the dehydrated products meet the desired quality standards. They must check the products for moisture content, color, and texture. They must also ensure that the products are free of contamination.

- Inspect dehydrated products to ensure they meet quality standards.

- Take corrective action if products do not meet quality standards.

4. Maintaining a Clean and Safe Work Environment

The operator is responsible for maintaining a clean and safe work area. They must follow all safety procedures and wear the appropriate personal protective equipment. They must also clean up any spills or debris.

- Follow all safety procedures and wear the appropriate personal protective equipment.

- Clean up any spills or debris to maintain a clean and safe work environment.

Interview Tips

Preparing for an interview for the position of Dehydrating Press Operator can be daunting. However, with some preparation and research, you can increase your chances of acing the interview and landing the job.

1. Research the Company and the Role

Before the interview, take some time to research the company and the specific role you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can research the company’s website, read industry publications, and network with people who work at the company.

- Visit the company’s website to learn about their mission, values, and products or services.

- Read industry publications to learn about the latest trends and best practices in the field.

- Network with people who work at the company to get insights into the company culture and the specific role you are applying for.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked in an interview for a Dehydrating Press Operator position. Some examples of common interview questions are “Tell me about yourself”, “Why are you interested in this position?”, and “What are your strengths and weaknesses?”. It can be helpful to practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

- Come up with a brief and engaging answer to the question “Tell me about yourself”.

- Prepare a few reasons why you are interested in the position and why you are a good fit for the company.

- Identify your strengths and weaknesses. Be honest about your weaknesses, but also emphasize how you are working to improve them.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will likely ask you about your experience and skills as a Dehydrating Press Operator. Be prepared to discuss your experience in detail, including your responsibilities, accomplishments, and any challenges you faced. You should also be prepared to discuss your skills, such as your ability to operate and maintain dehydrating presses, ensure product quality, and maintain a clean and safe work environment.

- Highlight your experience in operating and maintaining dehydrating presses.

- Discuss your skills in ensuring product quality, such as your ability to check the products for moisture content, color, and texture.

- Provide examples of how you have maintained a clean and safe work environment.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during the interview. This will show the interviewer that you are interested in the position and that you are a good fit for the company. Be polite and respectful to the interviewer, and answer their questions clearly and concisely. Make eye contact and dress appropriately.

- Be polite and respectful to the interviewer.

- Answer their questions clearly and concisely.

- Make eye contact and dress appropriately.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dehydrating Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dehydrating Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.