Are you gearing up for a career in Fiberglass Dowel Drawing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fiberglass Dowel Drawing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

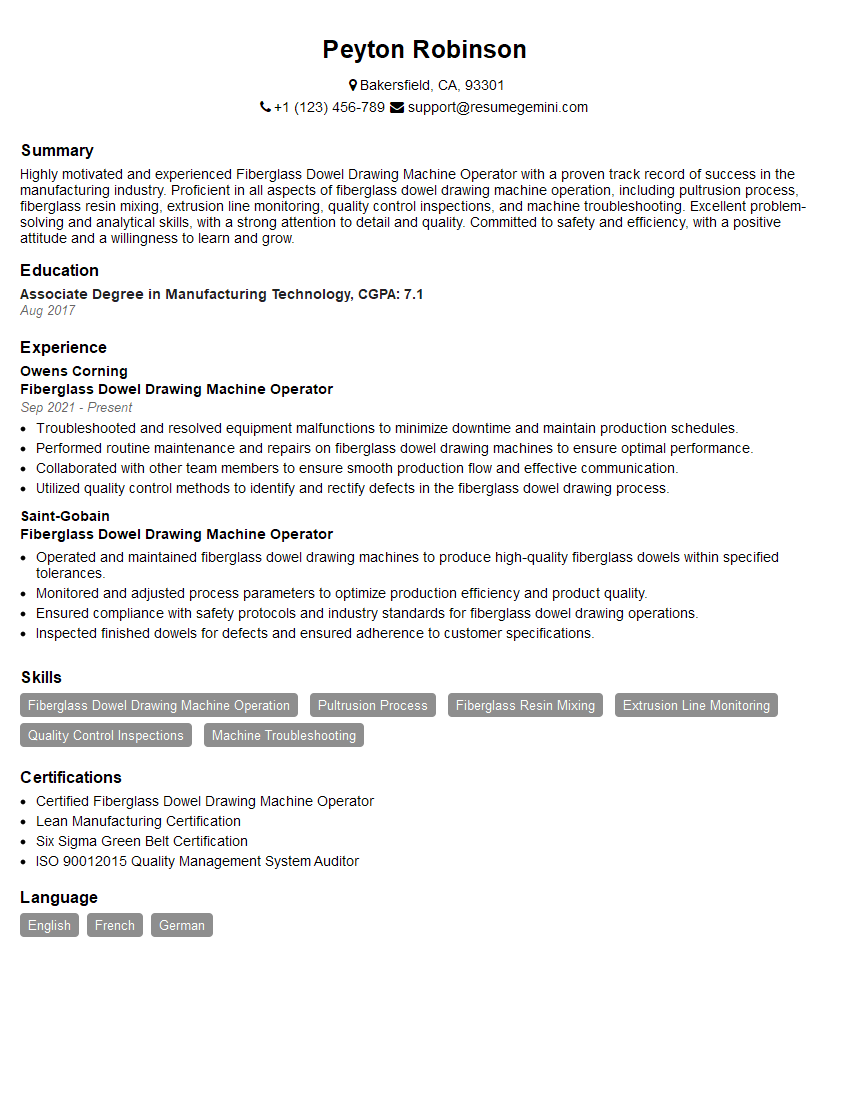

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Dowel Drawing Machine Operator

1. How do you ensure the production of high-quality fiberglass dowels using the drawing machine?

To ensure high-quality dowels, I follow these steps:

- Raw material inspection: I check the quality of fiberglass strands, binder, and sizing agents before the production process.

- Machine calibration: I ensure the drawing machine is properly calibrated to produce the desired diameter and tolerances.

- Process monitoring: During production, I monitor temperature, tension, and speed to optimize fiber alignment and resin distribution.

- Quality control: I perform regular inspections on finished dowels to ensure they meet specifications and customer requirements.

2. What safety precautions do you take when operating the fiberglass dowel drawing machine?

- PPE: I wear appropriate personal protective equipment, including gloves, safety glasses, and a mask, to prevent exposure to fiberglass fibers.

- Machine guards: I ensure machine guards are in place and operational to prevent contact with moving parts.

- Electrical safety: I check electrical connections and ground fault interrupters before operating the machine.

- Housekeeping: I maintain a clean work area to prevent slips and falls.

- Emergency procedures: I am familiar with emergency shutdown procedures and evacuation plans.

3. Describe the maintenance tasks you perform on the fiberglass dowel drawing machine.

- Daily: I lubricate moving parts, clean sensors, and check filters.

- Weekly: I inspect belts and tensioners, calibrate sensors, and clean the resin bath.

- Monthly: I perform a comprehensive inspection, including checking drive shafts, bearings, and electrical components.

- Annually: I work with maintenance personnel for major repairs or overhauls.

4. How do you troubleshoot common issues that can occur during fiberglass dowel drawing?

- Diameter variations: I check resin temperature, fiber alignment, and tension settings.

- Surface defects: I examine the drawing die for wear or damage, and adjust the operating temperature.

- Breakage: I investigate fiber strength, resin quality, and machine temperature.

- Uneven coating: I check the resin viscosity, nozzle alignment, and air pressure.

5. How do you optimize the production efficiency of the fiberglass dowel drawing machine?

- Process optimization: I analyze machine settings, identify bottlenecks, and make adjustments to improve cycle times.

- Preventive maintenance: I perform regular maintenance to prevent breakdowns and unplanned downtime.

- Collaboration: I work with upstream and downstream teams to optimize supply chain and logistics.

- Continuous improvement: I monitor production data, identify areas for improvement, and implement changes to increase efficiency.

6. What types of fiberglass dowels have you produced in previous roles?

I have experience producing a wide range of fiberglass dowels, including:

- Pultruded fiberglass dowels: I have optimized machine settings and resin formulations to produce high-strength, lightweight dowels for construction and automotive applications.

- Pultruded fiberglass dowels: I have developed production processes that meet tight tolerances for diameters, lengths, and surface finishes for electrical and electronic applications.

- Braided fiberglass dowels: I have worked with specialized machinery to produce braided fiberglass dowels with improved flexibility and impact resistance for medical devices and sporting goods.

7. How do you ensure the consistency of fiberglass dowels produced on the drawing machine?

- Raw material control: I establish specifications for fiberglass strands, binders, and sizing agents to ensure consistent quality.

- Machine calibration: I calibrate the machine regularly using precision measuring instruments to maintain accurate diameter and tolerance.

- Process control: I monitor process parameters such as temperature, tension, and speed, and make adjustments as necessary to optimize fiber alignment and resin distribution.

- Statistical process control (SPC): I use SPC techniques to collect and analyze production data, identify variations, and implement corrective actions.

8. How do you handle production deadlines and urgent orders?

- Prioritization: I assess the urgency of orders, prioritize them based on customer requirements, and allocate resources accordingly.

- Scheduling: I develop production schedules that optimize machine utilization and ensure timely delivery.

- Communication: I communicate with customers regularly to provide updates on progress and anticipate any potential delays.

- Flexibility: I can adjust my work schedule or collaborate with colleagues to meet tight deadlines without compromising quality.

9. What is your understanding of the different types of resins used in fiberglass dowel production?

- Polyester resin: I am familiar with the properties, application, and curing methods of polyester resin, which provides excellent strength, dimensional stability, and resistance to moisture.

- Epoxy resin: I understand the advantages of epoxy resin, including its high strength, chemical resistance, and ability to bond well to different surfaces.

- Phenolic resin: I have experience using phenolic resin in fiberglass dowels, appreciating its electrical insulation properties, heat resistance, and flame retardancy.

10. Describe your experience with quality control procedures in fiberglass dowel production.

- In-process quality control: I conduct regular inspections throughout the production process, checking for defects, dimensional accuracy, and surface finish.

- Statistical process control (SPC): I utilize SPC techniques to monitor production data and identify trends or variations that require corrective action.

- Final product inspection: I perform a thorough inspection of finished dowels, verifying compliance with specifications and customer requirements.

- Customer feedback: I actively seek customer feedback and use it to improve quality control measures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Dowel Drawing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Dowel Drawing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fiberglass Dowel Drawing Machine Operator is responsible for operating, maintaining, and troubleshooting fiberglass dowel drawing machines. They ensure the production of high-quality fiberglass dowels by monitoring and adjusting the machine’s settings, and performing necessary repairs and maintenance tasks.

1. Machine Operation

Operate fiberglass dowel drawing machines to produce dowels of various diameters and lengths.

- Set up and adjust machine parameters based on production specifications.

- Monitor machine operation and make adjustments to ensure optimal performance.

2. Material Handling

Load and unload fiberglass roving onto the machine.

- Inspect roving quality and identify any defects.

- Ensure proper tension and alignment of roving during the drawing process.

3. Quality Control

Inspect fiberglass dowels for defects, such as cracks, bubbles, or imperfections.

- Use measuring tools to verify dowel dimensions and tolerances.

- Maintain records of quality inspections and report any deviations from specifications.

4. Maintenance and Troubleshooting

Perform routine maintenance on fiberglass dowel drawing machines, including cleaning, lubrication, and adjustments.

- Identify and troubleshoot machine malfunctions and make necessary repairs.

- Coordinate with maintenance personnel for major repairs or replacements.

Interview Tips

Preparing for an interview for a Fiberglass Dowel Drawing Machine Operator position requires a combination of technical knowledge and soft skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific requirements of the Fiberglass Dowel Drawing Machine Operator role. This will enable you to tailor your answers to demonstrate your alignment with the company’s goals and the position’s responsibilities.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating and maintaining fiberglass dowel drawing machines. Quantify your accomplishments and provide specific examples of how you have contributed to improving production efficiency or quality.

3. Showcase Technical Proficiency

Demonstrate your understanding of the technical aspects of fiberglass dowel drawing. Be prepared to discuss machine parameters, material properties, and quality control procedures. This will indicate your technical competence and ability to handle the technical challenges of the position.

4. Emphasize Problem-Solving Abilities

Highlight your problem-solving skills and ability to troubleshoot machine malfunctions. Describe instances where you identified and resolved issues that impacted production or quality. This will demonstrate your ability to handle unexpected situations and maintain machine uptime.

5. Prepare for Behavioral Questions

Expect behavioral interview questions that delve into your work ethic, team player abilities, and attention to detail. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of how you have effectively handled challenges in previous roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Dowel Drawing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.