Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Glass Rolling Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Glass Rolling Machine Operator so you can tailor your answers to impress potential employers.

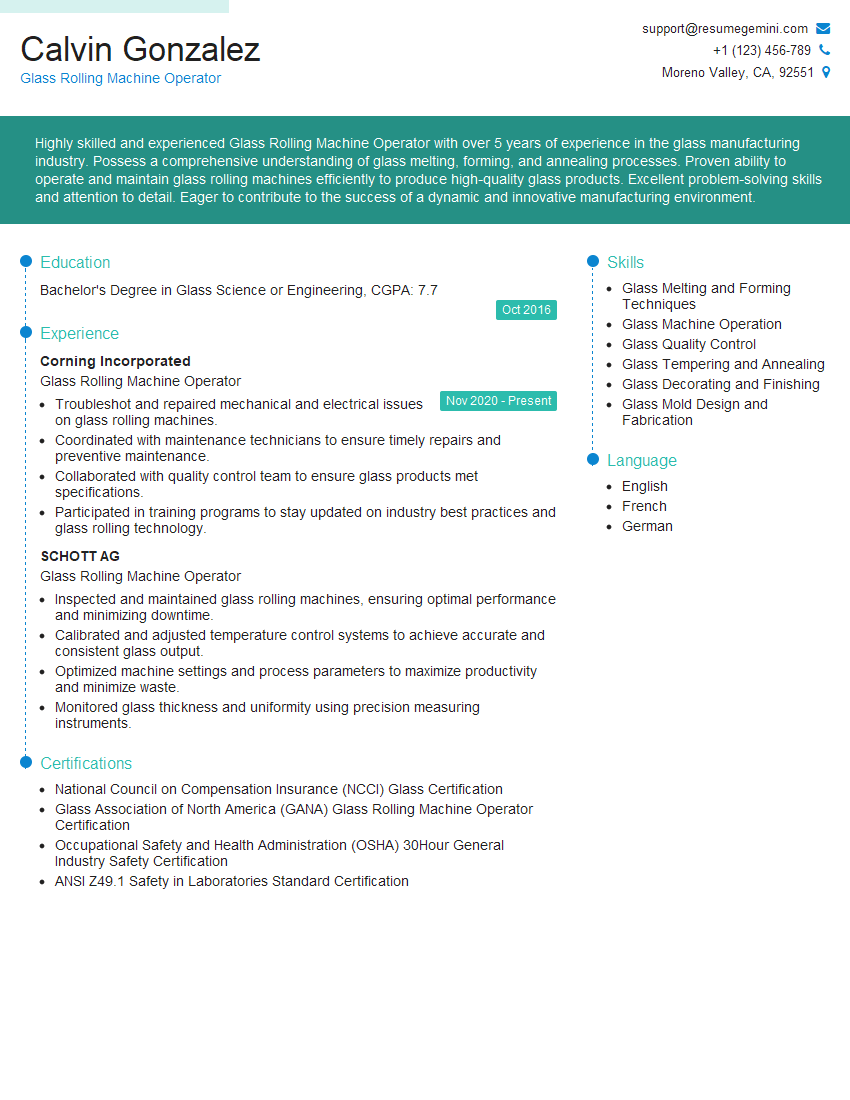

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Rolling Machine Operator

1. What are the key steps involved in the glass rolling process?

The key steps involved in the glass rolling process include:

- Preparing the raw materials

- Melting the glass

- Forming the glass

- Annealing the glass

- Inspecting the glass

2. What are the different types of glass rolling machines?

Horizontal rolling machines

- Used to produce flat glass

- The glass is fed into the machine horizontally and rolled between two rollers

Vertical rolling machines

- Used to produce cylindrical glass

- The glass is fed into the machine vertically and rolled between two rollers

Float glass machines

- Used to produce flat glass

- The glass is floated on a bed of molten metal

3. What are the main challenges in operating a glass rolling machine?

The main challenges in operating a glass rolling machine include:

- Maintaining the correct temperature of the glass

- Ensuring that the glass is rolled to the correct thickness

- Preventing the glass from breaking

- Keeping the machine clean and free of debris

4. What are the safety precautions that must be taken when operating a glass rolling machine?

The safety precautions that must be taken when operating a glass rolling machine include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and a hard hat

- Keeping the work area clean and free of debris

- Being aware of the location of emergency stop buttons

- Following all safety procedures

5. What are the maintenance tasks that are typically performed on a glass rolling machine?

The maintenance tasks that are typically performed on a glass rolling machine include:

- Inspecting the machine for wear and tear

- Lubricating the machine

- Cleaning the machine

- Calibrating the machine

- Replacing worn parts

6. What are the troubleshooting steps that can be taken when a glass rolling machine is not operating properly?

The troubleshooting steps that can be taken when a glass rolling machine is not operating properly include:

- Checking the power supply

- Checking the hydraulic system

- Checking the electrical system

- Checking the mechanical system

- Consulting the machine’s manual

7. What are the quality control procedures that are used to ensure that the glass produced by a glass rolling machine meets specifications?

The quality control procedures that are used to ensure that the glass produced by a glass rolling machine meets specifications include:

- Inspecting the glass for defects

- Measuring the thickness of the glass

- Testing the strength of the glass

- Maintaining records of all quality control checks

8. What are the environmental regulations that apply to the operation of a glass rolling machine?

The environmental regulations that apply to the operation of a glass rolling machine include:

- Regulations on air pollution

- Regulations on water pollution

- Regulations on solid waste disposal

- Regulations on noise pollution

9. What are the future trends in the glass rolling industry?

The future trends in the glass rolling industry include:

- The development of new glass rolling technologies

- The increasing use of recycled glass

- The growing demand for glass products

10. What are your strengths and weaknesses as a glass rolling machine operator?

My strengths as a glass rolling machine operator include:

- I have a strong understanding of the glass rolling process.

- I am experienced in operating a variety of glass rolling machines.

- I am able to produce high-quality glass products.

- I am a team player and I am always willing to help others.

My weaknesses as a glass rolling machine operator include:

- I am sometimes too focused on my work and I can be forgetful.

- I am not always the best at communicating with others.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Rolling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Rolling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Rolling Machine Operators are responsible for the proper operation and maintenance of glass rolling machines. They work in various industries, including glass manufacturing, automotive, and construction, to produce a wide range of glass products.

1. Machine Operation

Glass Rolling Machine Operators are responsible for the smooth and efficient operation of their machines. Their key tasks include:

- Loading and unloading glass sheets onto the machine

- Setting up and adjusting machine parameters, such as temperature, speed, and pressure

- Monitoring the machine during operation and making necessary adjustments

- Troubleshooting and resolving any technical issues

- Maintaining a safe and clean work environment

2. Quality Control

Glass Rolling Machine Operators are also responsible for ensuring the quality of the glass products produced by their machines. They perform various quality checks throughout the rolling process, including:

- Inspecting glass sheets for defects, such as scratches, bubbles, or cracks

- Measuring and verifying the dimensions and thickness of glass sheets

- Maintaining records of quality control checks

- Reporting any quality issues to their supervisors

3. Maintenance and Repair

Glass Rolling Machine Operators are also responsible for maintaining and repairing their machines. They perform routine maintenance tasks, such as:

- Lubricating and cleaning machine components

- Inspecting machine parts for wear and tear

- Replacing faulty or damaged parts

- Performing minor repairs as needed

4. Training and Supervision

Glass Rolling Machine Operators may also be responsible for training new employees and supervising their work. They provide guidance and support to ensure that new employees are able to operate the machine safely and efficiently. Additionally, they may oversee the work of other operators, ensuring that quality standards are maintained and production targets are met.

Interview Tips

Preparing thoroughly for an interview is crucial to showcasing your skills and qualifications effectively. Here are some tips to help you ace your interview for a Glass Rolling Machine Operator position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand their business, culture, and the requirements of the role. You can gather information from the company’s website, LinkedIn page, and industry news articles.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. Practice delivering your responses clearly and concisely, highlighting your relevant skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

3. Highlight Your Technical Skills

As a Glass Rolling Machine Operator, strong technical skills are essential. In your interview, emphasize your proficiency in operating and maintaining glass rolling machines. Describe your experience with different types of machines, and discuss your understanding of the rolling process and quality control techniques.

4. Showcase Your Problem-Solving Abilities

Glass Rolling Machine Operators often encounter technical issues during their work. In the interview, demonstrate your problem-solving abilities by providing examples of how you have identified and resolved machine malfunctions or quality problems in the past. Highlight your analytical thinking, troubleshooting skills, and attention to detail.

5. Emphasize Safety and Quality

Safety and quality are paramount in glass manufacturing. In your interview, emphasize your commitment to maintaining a safe work environment and producing high-quality products. Share examples of your safety practices, quality control measures, and continuous improvement initiatives.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Rolling Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.