Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hydraulic Billet Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

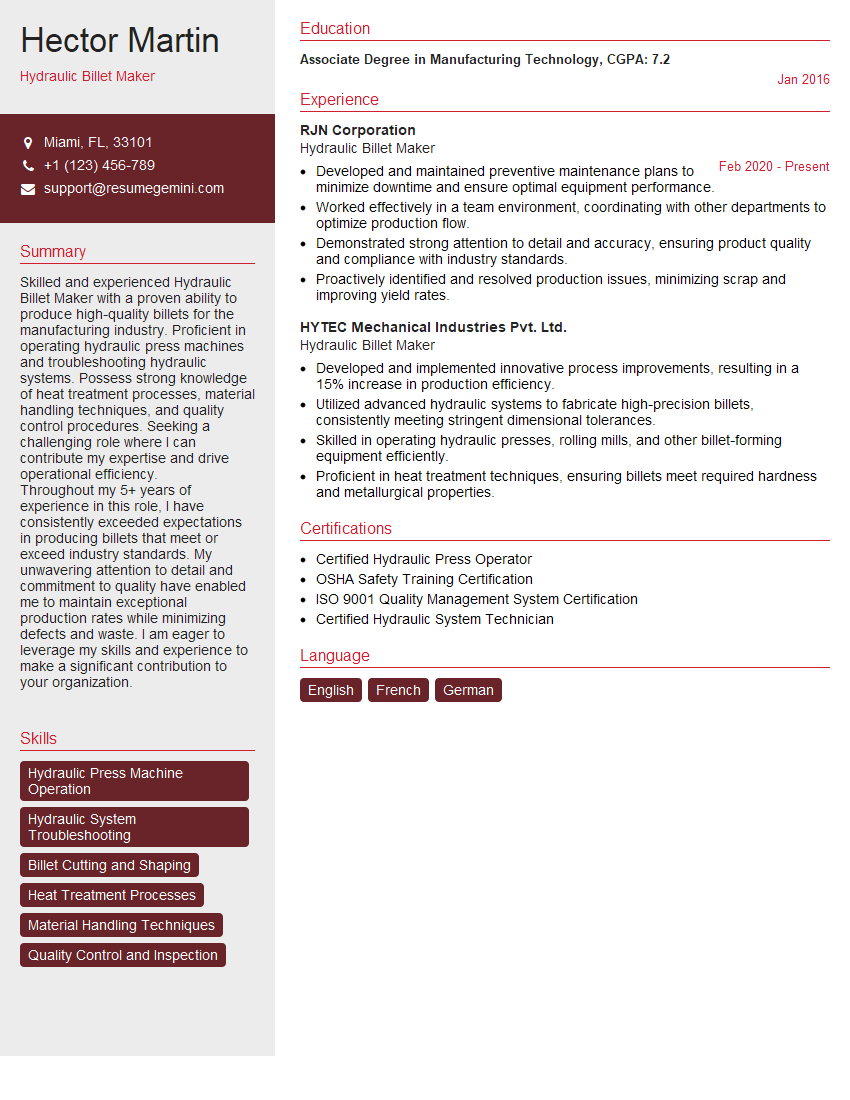

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Billet Maker

1. What are the key components of a hydraulic billet maker?

The primary components of a hydraulic billet maker include:

- Hydraulic power unit (HPU): Generates and controls hydraulic pressure.

- Hydraulic cylinder: Converts hydraulic pressure into mechanical force to move the billet.

- Billet container: Holds the billet during the extrusion process.

- Die: Shapes the billet as it is extruded.

- Control system: Monitors and adjusts process parameters, such as pressure and temperature.

2. Describe the extrusion process used in hydraulic billet making.

The extrusion process involves:

Billet Preparation:

- Billet heated to a specific temperature for increased ductility.

Extrusion:

- Billet placed in the billet container.

- Hydraulic pressure applied to the billet, forcing it through the die.

- Billet takes the shape of the die.

3. What factors influence the quality of a hydraulic billet?

Critical factors include:

- Material properties of the billet.

- Temperature and pressure during extrusion.

- Die design and condition.

- Control system accuracy.

- Maintenance and calibration of equipment.

4. How do you ensure the safety of personnel operating a hydraulic billet maker?

Safety measures include:

- Regular inspection and maintenance.

- Proper training for operators.

- Safety guards and emergency stops.

- Compliance with safety regulations.

5. What troubleshooting steps would you take if a billet gets stuck during extrusion?

I would first:

- Check hydraulic pressure and adjust if necessary.

- Inspect the die for damage or blockage.

- Lubricate the billet and container.

- Restart the extrusion process gradually.

- If the problem persists, I would consult the manufacturer or experienced technician.

6. What maintenance practices are crucial for a hydraulic billet maker?

Regular maintenance tasks include:

- Lubricating moving parts.

- Checking hydraulic oil levels and replacing as needed.

- Inspecting hydraulic hoses and fittings for leaks or damage.

- Calibrating pressure sensors and control systems.

- Scheduled overhauls to prevent breakdowns.

7. How do you calculate the force required for billet extrusion?

The force (F) can be calculated using the formula: F = A * P where:

- A is the cross-sectional area of the billet.

- P is the hydraulic pressure applied.

8. What methods can be used to improve the efficiency of a hydraulic billet maker?

Efficiency can be enhanced by:

- Optimizing hydraulic pressure and flow rates.

- Minimizing friction and wear in moving parts.

- Using efficient die designs.

- Controlling and optimizing process parameters.

- Implementing automation and controls.

9. How do you handle variation in billet material properties?

I would:

- Adjust extrusion parameters (pressure, temperature, speed) to accommodate material variations.

- Monitor billet quality closely and make necessary adjustments.

- Work closely with suppliers to ensure consistent billet quality.

10. Explain how you would use data analysis to optimize the billet making process.

I would use data analysis to:

- Identify trends and patterns in process parameters.

- Correlate billet quality with specific process conditions.

- Develop models to predict optimal extrusion settings for different billet materials.

- Monitor and control process variables to improve consistency and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Billet Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Billet Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Billet Makers are pivotal figures within the steel industry, entrusted with the critical task of creating and maintaining top-notch billets. These skilled professionals must possess a comprehensive understanding of metallurgy, hydraulic systems, and quality control processes.

1. Billet Production and Management

The primary responsibility of a Hydraulic Billet Maker revolves around the production and management of high-quality billets, ensuring they meet stringent specifications and client requirements.

- Expertly operate hydraulic presses to apply precise pressure and form billets from steel blooms or slabs.

- Continuously monitor and adjust process parameters, such as temperature, pressure, and cycle time, to optimize billet quality and minimize defects.

- Conduct thorough inspections and measurements throughout the production process to ensure adherence to quality standards.

- Maintain accurate records and document all production data for quality control and traceability purposes.

2. Equipment Maintenance and Troubleshooting

Hydraulic Billet Makers are also responsible for the upkeep and troubleshooting of hydraulic presses and related equipment.

- Regularly inspect and maintain hydraulic systems, including pumps, valves, and cylinders, to prevent breakdowns and ensure optimal performance.

- Troubleshoot and resolve equipment malfunctions promptly, minimizing downtime and maintaining production efficiency.

- Conduct preventive maintenance tasks as per established schedules to extend equipment lifespan and reduce repair costs.

- Coordinate with maintenance teams to ensure timely repairs and upgrades of hydraulic systems.

3. Safety and Compliance

Upholding safety protocols and ensuring regulatory compliance are paramount for Hydraulic Billet Makers.

- Strictly follow established safety guidelines and wear appropriate personal protective equipment (PPE) while operating hydraulic presses.

- Adhere to environmental regulations and guidelines to minimize the environmental impact of billet production.

- Receive and understand safety briefings, training, and updates to stay abreast of industry best practices.

- Report any safety hazards or concerns promptly to supervisors and management.

4. Continuous Improvement

Hydraulic Billet Makers are committed to continuous improvement and staying updated with advancements in the field.

- Actively participate in training programs and workshops to enhance their technical skills and knowledge.

- Collaborate with colleagues, supervisors, and engineers to identify areas for process improvement and productivity gains.

- Stay abreast of industry trends, technologies, and best practices through professional development activities.

- Contribute to the development and implementation of new techniques and methodologies to enhance billet quality and production efficiency.

Interview Tips

Succeeding in an interview for the role of Hydraulic Billet Maker requires meticulous preparation and a well-structured approach. Here are some invaluable tips to help you ace your interview:

1. Research the Company and Industry

Before stepping into the interview room, take the time to thoroughly research the company, its products, and the steel industry as a whole. This knowledge will demonstrate your genuine interest and preparedness.

- Visit the company’s website to gather information about their history, mission, and current projects.

- Familiarize yourself with the industry’s latest trends and technologies through reputable sources.

- Read industry-specific publications and attend webinars to stay updated on advancements in billet production.

2. Highlight Relevant Skills and Experience

During the interview, confidently articulate your technical skills, experience, and qualifications that align with the key job responsibilities.

- Quantify your accomplishments and provide specific examples to demonstrate your proficiency in billet production, equipment maintenance, and quality control.

- Emphasize your understanding of hydraulic systems, metallurgy, and safety protocols.

- Discuss your experience in working independently and as part of a team.

3. Prepare for Technical Questions

Interviewers may delve into technical aspects of billet production to assess your knowledge and expertise.

- Review the principles of hydraulic press operation and billet forming.

- Familiarize yourself with common types of steel defects and their causes.

- Practice troubleshooting scenarios related to hydraulic systems and billet production equipment.

- Prepare to discuss your understanding of quality control standards and inspection techniques.

4. Showcase Safety Consciousness

Safety is paramount in the steel industry. Emphasize your commitment to safety and your understanding of safety protocols.

- Highlight your experience in following safety guidelines and using proper PPE.

- Discuss your knowledge of industry safety regulations and your role in maintaining a safe work environment.

- Explain how you prioritize safety in your daily tasks and decision-making.

5. Express Enthusiasm and Career Goals

Convey your enthusiasm for the role and the steel industry. Explain your career aspirations and how this position aligns with your long-term goals.

- Share your passion for metallurgy and the manufacturing process.

- Discuss your desire to contribute to the production of high-quality steel billets.

- Express your willingness to learn and grow within the company.

Next Step:

Now that you’re armed with the knowledge of Hydraulic Billet Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hydraulic Billet Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini