Are you gearing up for an interview for a Hot Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hot Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

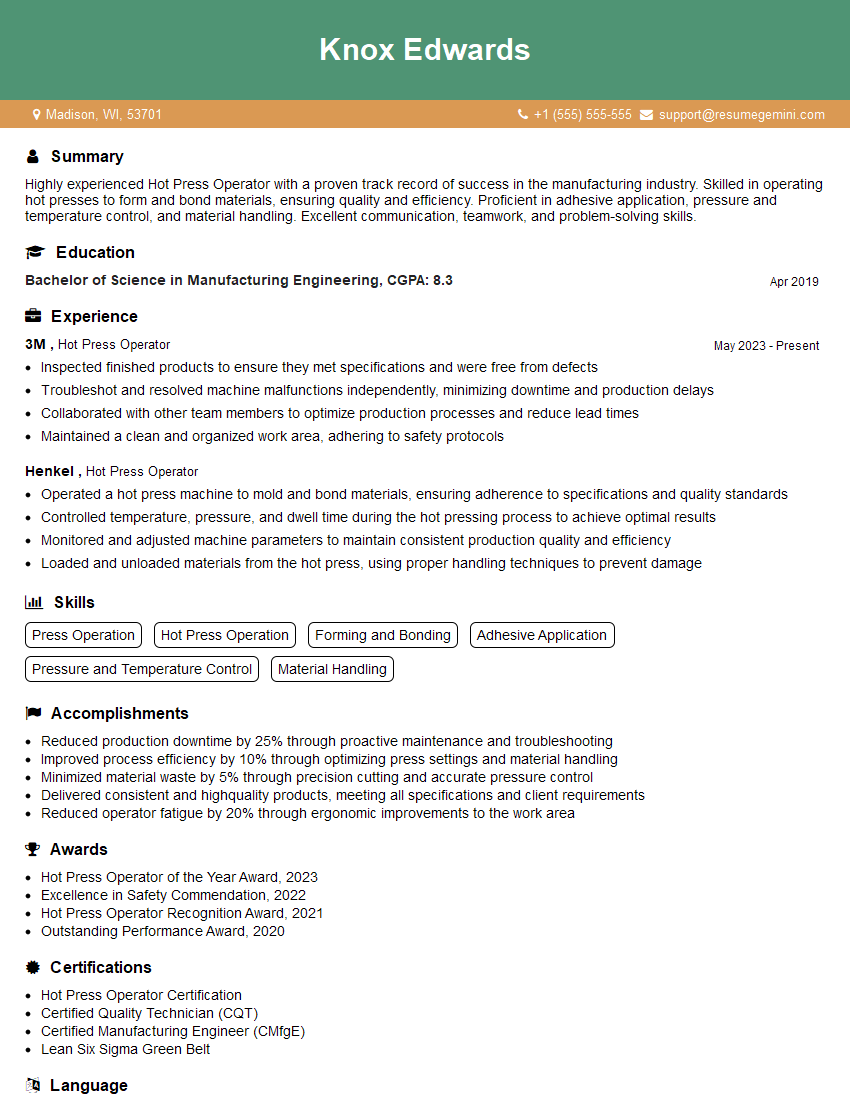

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Press Operator

1. How would you correct a defect in laminate caused by blistering due to entrapped air?

To correct a defect in laminate caused by blistering due to entrapped air, I would follow these steps:

- Identify the location and extent of the blister.

- Use a sharp blade to carefully cut a small opening in the blister.

- Insert a syringe into the opening and slowly inject a small amount of adhesive into the blister.

- Apply pressure to the blister to force the adhesive into the void and remove the entrapped air.

- Clamp the area to hold the laminate in place while the adhesive cures.

2. How do you determine the correct pressing temperature and pressure for a specific laminate material?

Consulting the manufacturer’s specifications

- The first step is to consult the manufacturer’s specifications for the laminate material you are using.

- These specifications will typically include recommended pressing temperatures and pressures.

Conducting a test press

- If the manufacturer’s specifications are not available, or if you are unsure about the accuracy of the specifications, you can conduct a test press.

- This involves pressing a small sample of the laminate material at different temperatures and pressures to determine the optimal settings.

3. What are the common quality defects associated with hot pressing and how do you prevent them?

Some common quality defects associated with hot pressing and how to prevent them include:

- Entrapped air: This can be prevented by using a vacuum press or by pressing the laminate under high pressure.

- Blistering: This can be prevented by using a release agent or by pressing the laminate at a low temperature.

- Wrinkling: This can be prevented by using a backing material or by pressing the laminate at a high temperature.

- Delamination: This can be prevented by using a high-quality adhesive and by pressing the laminate at the correct temperature and pressure.

4. How do you troubleshoot a hot press that is not heating evenly?

If a hot press is not heating evenly, there are a few things you can check:

- The heating elements: Make sure that the heating elements are all functioning properly and that they are making good contact with the platens.

- The temperature controller: Make sure that the temperature controller is functioning properly and that it is set to the correct temperature.

- The insulation: Make sure that the insulation around the hot press is in good condition and that it is not allowing heat to escape.

5. How do you maintain a hot press?

To maintain a hot press, you should:

- Clean the platens regularly. This will help to prevent the build-up of adhesive and other debris, which can affect the quality of the bond.

- Inspect the heating elements and temperature controller regularly. This will help to ensure that they are functioning properly and that the hot press is maintaining the correct temperature.

- Lubricate the moving parts regularly. This will help to prevent wear and tear and extend the life of the hot press.

6. What are the safety precautions that should be taken when operating a hot press?

When operating a hot press, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Be aware of the location of the emergency stop button and how to use it.

- Never place your hands or fingers between the platens.

- Allow the hot press to cool down completely before performing any maintenance or repairs.

7. What is the difference between a hot press and a cold press?

A hot press is a machine that uses heat and pressure to bond materials together. A cold press, on the other hand, uses only pressure to bond materials together.

- Hot presses are typically used for bonding materials that are thermoplastic, meaning that they can be softened by heat. Cold presses are typically used for bonding materials that are thermoset, meaning that they cannot be softened by heat.

- Hot presses can produce stronger bonds than cold presses, but they can also damage delicate materials. Cold presses are gentler on materials, but they can take longer to produce a bond.

8. What are the different types of hot presses?

There are three main types of hot presses:

- Platen presses: Platen presses have two flat platens that are heated and pressed together to bond the materials.

- Vacuum presses: Vacuum presses use a vacuum to remove the air from between the materials before they are pressed together. This helps to create a stronger bond.

- Continuous presses: Continuous presses are used for bonding long, continuous materials, such as fabric or paper.

9. What are the applications of hot pressing?

Hot pressing is used in a wide variety of applications, including:

- Laminating: Hot pressing is used to laminate materials together, such as wood, plastic, and metal.

- Bonding: Hot pressing is used to bond materials together, such as rubber, fabric, and composites.

- Molding: Hot pressing is used to mold materials into specific shapes, such as plastic parts and rubber products.

10. What are the advantages of hot pressing?

Hot pressing offers a number of advantages, including:

- Strong bonds: Hot pressing can produce strong bonds between materials.

- Versatility: Hot pressing can be used to bond a wide variety of materials.

- Efficiency: Hot pressing can be a fast and efficient way to bond materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Press Operators are responsible for operating and maintaining hot press machines used in the manufacture of various products, such as laminates, veneers, and composite materials.

1. Machine Operation

Operate hot press machines to bond materials together using heat and pressure.

- Load and unload materials into and out of the press.

- Monitor machine settings, such as temperature, pressure, and cycle time.

2. Quality Control

Inspect materials before and after pressing to ensure they meet quality standards.

- Identify and correct defects in materials or products.

- Maintain records of quality control checks.

3. Maintenance

Perform basic maintenance on hot press machines, such as cleaning, lubrication, and minor repairs.

- Troubleshoot and resolve machine malfunctions.

- Follow established safety procedures.

4. Training

Train new operators on the safe and efficient operation of hot press machines.

- Provide guidance and support to new employees.

- Stay updated on the latest industry best practices.

Interview Tips

Preparing for a Hot Press Operator interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company and the specific role you are applying for. This shows the interviewer that you are genuinely interested in the position and have taken the initiative to gather information.

- Visit the company website to learn about their products, services, and culture.

- Review the job description thoroughly and identify the key skills and qualifications required.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. Practicing your responses will help you feel more confident and organized during the interview.

- Example Outline:

- Tell me about your experience operating hot press machines.

- How do you ensure the quality of the products you produce?

- Describe a time when you had to troubleshoot a malfunctioning hot press machine.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your capabilities.

- Example: “In my previous role, I operated a hot press machine to produce high-quality laminates. I consistently met or exceeded production targets while maintaining a high level of product quality.”

4. Show Enthusiasm and a Positive Attitude

Convey your enthusiasm for the position and the industry. A positive attitude and a willingness to learn are highly valued by employers.

- Example: “I am eager to contribute my skills and experience to your team. I am particularly interested in the company’s commitment to innovation and quality.”

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your interest in the company and the role.

- Example: “I am impressed by the company’s growth trajectory. Can you share more about the company’s future plans and how this position fits into those plans?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!