Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Scrap Baler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

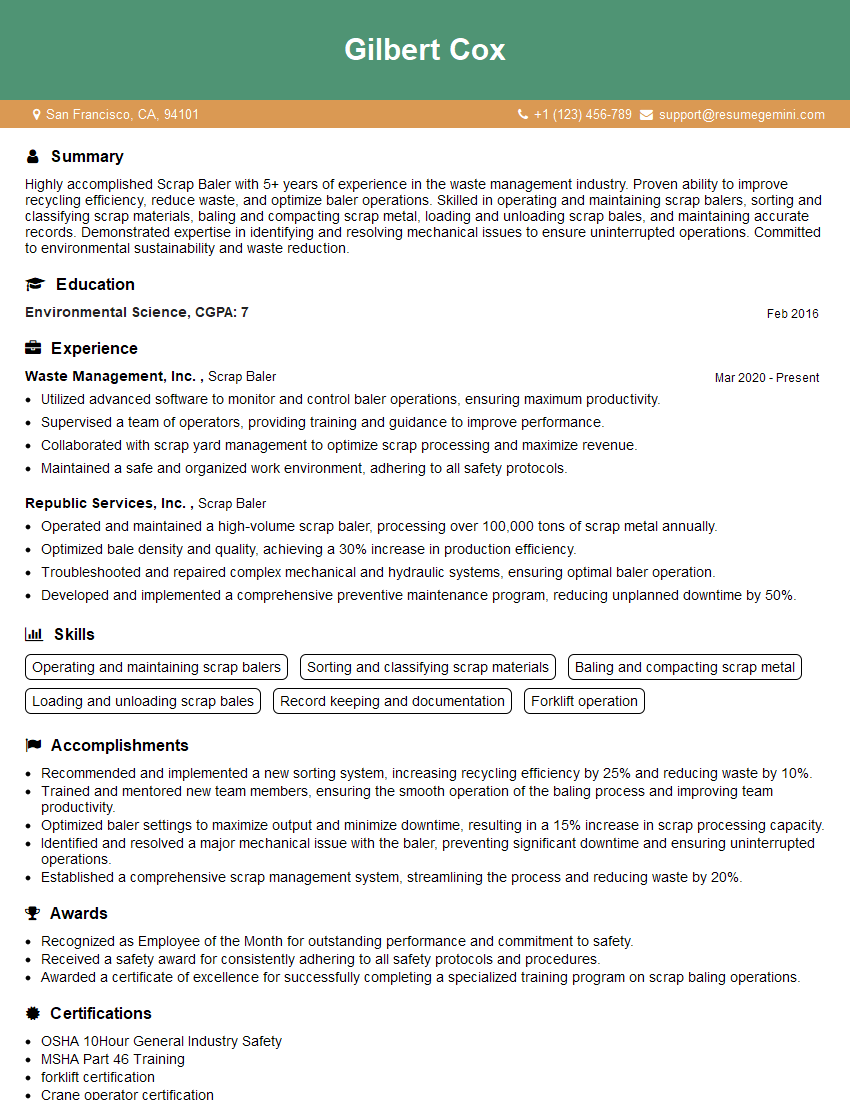

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scrap Baler

1. What are the different types of scrap balers and their applications?

- Horizontal balers: Used for compressing large volumes of material, such as cardboard, paper, and plastics. They are typically used in warehouses and recycling centers.

- Vertical balers: Used for compressing smaller volumes of material, such as metal, cans, and bottles. They are often used in retail stores, offices, and schools.

- Two-ram balers: Used for compressing high-density materials, such as aluminum, copper, and steel. They are typically used in industrial settings.

- Shear balers: Used for shearing large pieces of metal into smaller pieces. They are often used in scrap yards and recycling centers.

2. Describe the process of baling scrap metal.

Loading

- The scrap metal is loaded into the baler’s chamber.

- The chamber is closed and the ram begins to compress the metal.

Compression

- The ram continues to compress the metal until it reaches a predetermined density.

- The bale is then tied off with wire or banding.

Ejection

- The bale is ejected from the chamber and is ready to be shipped to a recycling facility.

3. What are the safety precautions that must be taken when operating a scrap baler?

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Never operate the baler while under the influence of drugs or alcohol.

- Never attempt to clear a jam by hand.

- Keep the baler area clean and free of debris.

- Follow all manufacturer’s instructions for safe operation.

4. What are the common causes of scrap baler malfunctions?

- Overloading the chamber

- Using the wrong type of material

- Improper maintenance

- Electrical problems

- Hydraulic problems

5. How do you troubleshoot a scrap baler that is not working properly?

- Check the power supply.

- Check the hydraulic fluid level.

- Check the electrical connections.

- Look for any loose or damaged parts.

- Refer to the manufacturer’s troubleshooting guide.

6. What are the maintenance procedures that should be performed on a scrap baler?

- Daily: Check the fluid levels, lubricate the moving parts, and clean the baler.

- Weekly: Inspect the electrical connections, check the belts and chains for wear, and tighten any loose bolts.

- Monthly: Change the hydraulic fluid and filter, and perform a thorough inspection of the baler.

- Annually: Have the baler serviced by a qualified technician.

7. What are the environmental benefits of recycling scrap metal?

- Reduces greenhouse gas emissions.

- Conserves natural resources.

- Reduces air and water pollution.

- Creates jobs.

8. What are the different grades of scrap metal?

- Ferrous metals: Iron and steel

- Non-ferrous metals: Aluminum, copper, brass, and stainless steel

- Mixed metals: A combination of ferrous and non-ferrous metals

9. What are the factors that affect the price of scrap metal?

- The type of metal

- The grade of the metal

- The quantity of metal

- The location of the metal

- The current market demand for metal

10. What are the career opportunities in the scrap metal industry?

- Scrap metal processor

- Scrap metal broker

- Scrap metal dealer

- Scrap metal recycler

- Scrap metal equipment operator

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scrap Baler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scrap Baler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scrap Balers play a crucial role in waste management and recycling facilities. Below are some key job responsibilities of a Scrap Baler:

1. Scrap Handling and Preparation

- Receive and sort scrap metal, ensuring conformance to quality standards.

- Prepare scrap metal for baling, removing contaminants, and ensuring proper sizing.

2. Baler Operation

- Operate baling machines to compress scrap metal into manageable and transportable bales.

- Adjust machine settings and monitor baling processes to ensure optimal performance.

3. Bale Handling and Storage

- Move and stack bales safely and efficiently using appropriate equipment.

- Maintain an organized bale storage area, ensuring proper inventory management.

4. Equipment Maintenance

- Perform routine maintenance and inspections on baling machines and related equipment.

- Identify and diagnose minor issues, taking prompt action to resolve them.

5. Safety and Compliance

- Adhere to safety regulations and protocols, promoting a safe work environment.

- Wear appropriate safety gear and follow established procedures for handling heavy machinery.

Interview Tips

To ace an interview for a Scrap Baler position, candidates can consider the following tips:

1. Preparation and Research

- Understand the specific requirements and duties of the role.

- Research the company and industry to demonstrate your knowledge and interest.

2. Highlight Relevant Skills and Experience

- Emphasize any prior experience in scrap handling, baling operations, or equipment maintenance.

- Provide specific examples of your ability to safely and efficiently operate scrap balers.

3. Safety and Compliance Knowledge

- Demonstrate your understanding of industry regulations and safety protocols.

- Highlight your commitment to maintaining a safe and productive work environment.

4. Teamwork and Communication Skills

- Emphasize your ability to work effectively as part of a team.

- Highlight your communication skills, both verbal and written, to ensure smooth coordination.

5. Problem-Solving and Adaptability

- Provide examples of your ability to identify and resolve issues in a timely manner.

- Demonstrate your adaptability to changing work conditions and requirements.

6. Additional Considerations

- Be prepared to discuss your physical ability to perform the required tasks, such as lifting heavy objects.

- Consider any certifications or training relevant to the role, such as forklift operation or safety training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scrap Baler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.