Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rubber Tubing Splicer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

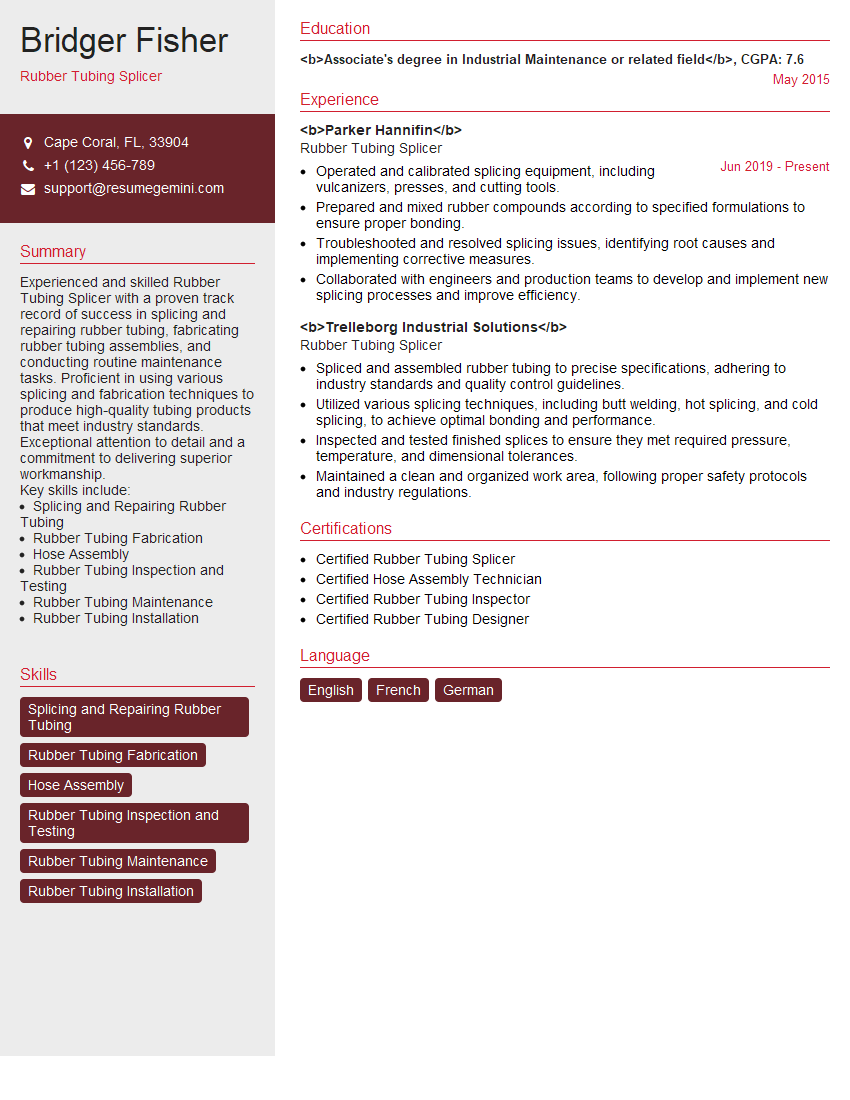

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Tubing Splicer

1. Explain the different types of rubber tubing splices and their applications?

- Compression splice: It is the most common type of splice used for joining two ends of rubber tubing. It involves using a mechanical clamp to compress the tubing together at the joint.

- Scarf splice: This splice is used when a stronger joint is required. It involves cutting the ends of the tubing at an angle and then overlapping them and adhering them together with an adhesive.

- Butt splice: This splice is used when a more flexible joint is required. It involves cutting the ends of the tubing straight and then butting them together and adhering them with an adhesive.

2. What are the different types of rubber tubing materials and their properties?

- Natural rubber: This type of rubber is made from the sap of rubber trees and is known for its high strength, elasticity, and resistance to wear and tear.

- Synthetic rubber: This type of rubber is made from synthetic materials and is known for its resistance to heat, oil, and chemicals.

- Silicone rubber: This type of rubber is made from silicone and is known for its high heat resistance and biocompatibility.

3. What are the different methods of preparing rubber tubing for splicing?

- Cutting: The tubing is cut to the desired length using a sharp knife or scissors.

- Cleaning: The tubing is cleaned to remove any dirt or debris using a solvent or detergent.

- Buffing: The ends of the tubing are buffed to smooth the edges and remove any burrs.

4. What are the different tools and equipment used for rubber tubing splicing?

- Splicing machine: This machine is used to compress the tubing together at the joint.

- Adhesive: This is used to adhere the tubing together at the joint.

- Clamps: These are used to hold the tubing in place while it is being spliced.

5. What are the different safety precautions that must be taken when splicing rubber tubing?

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator.

- Ensure that the splicing area is well-ventilated.

- Follow the manufacturer’s instructions for the splicing machine and adhesive.

6. What are the different factors that affect the strength of a rubber tubing splice?

- The type of splice

- The type of rubber tubing

- The preparation of the tubing

- The splicing technique

7. What are the different applications of rubber tubing splices?

- Conveying fluids

- Connecting components

- Sealing openings

8. What are the different troubleshooting tips for rubber tubing splices?

- If the splice is leaking, check the following:

- The splice is properly prepared

- The adhesive is properly applied

- The splice is properly compressed

9. What are the different industry standards for rubber tubing splices?

- ASTM D3139: Standard Test Method for Rubber Tubing

- ISO 3994: Rubber Tubing – Requirements and Test Methods

10. What are the different career opportunities for rubber tubing splicers?

- Production Supervisor

- Quality Control Inspector

- Maintenance Technician

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Tubing Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Tubing Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Rubber Tubing Splicer, you will be responsible for splicing together rubber tubing to create a continuous length. This is a critical process in the production of rubber tubing, as it ensures that the tubing is strong and durable.

1. Prepare the tubing

The first step in splicing rubber tubing is to prepare the ends of the tubing. This involves cutting the tubing to the desired length and then cleaning the ends to remove any dirt or debris.

- Cut the tubing to the desired length using a sharp knife.

- Clean the ends of the tubing using a solvent to remove any dirt or debris.

2. Apply the adhesive

Once the ends of the tubing have been prepared, the next step is to apply an adhesive to the ends. This adhesive will help to hold the tubing together when it is spliced.

- Apply a thin layer of adhesive to one end of the tubing.

- Apply a thin layer of adhesive to the other end of the tubing.

3. Splice the tubing

Once the adhesive has been applied, the next step is to splice the tubing together. This is done by pressing the two ends of the tubing together and holding them in place until the adhesive has dried.

- Press the two ends of the tubing together.

- Hold the tubing in place until the adhesive has dried.

4. Inspect the splice

Once the splice has dried, it is important to inspect it to make sure that it is strong and durable. This can be done by visually inspecting the splice and by pulling on the tubing to make sure that it is secure.

- Visually inspect the splice to make sure that it is smooth and even.

- Pull on the tubing to make sure that it is secure.

Interview Tips

There are a few things you can do to prepare for your interview for a Rubber Tubing Splicer position. First, take some time to research the company and the position itself. This will help you to understand the company’s culture and what they are looking for in a qualified candidate.

1. Practice your answers to common interview questions.

There are a few common interview questions that you are likely to be asked in an interview for a Rubber Tubing Splicer position. These questions include:

- “Tell me about your experience with splicing rubber tubing.”

- “What are the different types of adhesives that can be used to splice rubber tubing?”

- “How do you inspect a rubber tubing splice to ensure that it is strong and durable?”

2. Come prepared to talk about your qualifications.

In addition to practicing your answers to common interview questions, you should also come prepared to talk about your qualifications. This includes your education, experience, and skills. Be sure to highlight any experience that you have with splicing rubber tubing, as well as any other skills that would be relevant to the position.

3. Dress professionally and arrive on time.

It is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you are respectful of their time.

4. Be confident and enthusiastic.

Be confident and enthusiastic in your interview. This will help the interviewer to see that you are passionate about the position and that you are confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Tubing Splicer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.