Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Stem Roller interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Stem Roller so you can tailor your answers to impress potential employers.

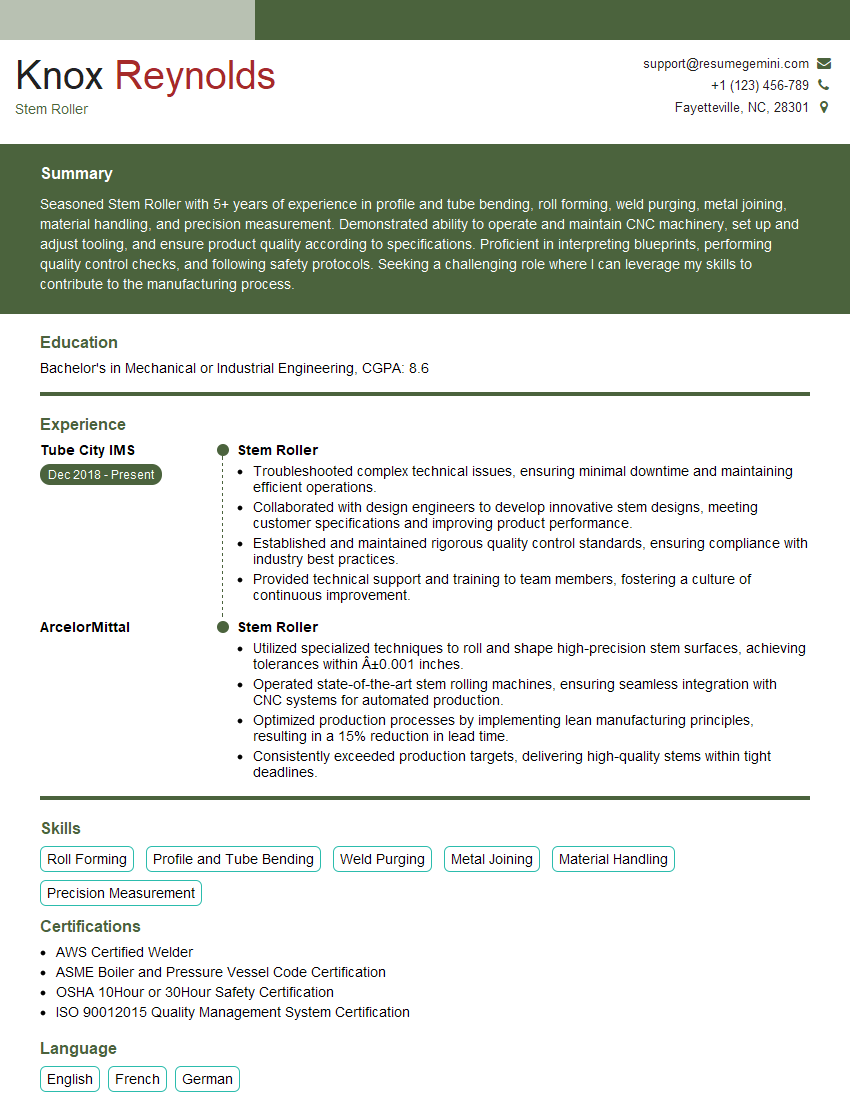

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stem Roller

1. Describe the process of cold rolling and its advantages over hot rolling?

- Cold rolling involves passing metal through rollers at room temperature, while hot rolling involves passing metal through rollers at elevated temperatures.

- Cold rolling produces a smoother, more precise finish and tighter tolerances.

- It increases the strength and hardness of the metal due to work hardening.

- Cold rolling can result in a higher yield strength while maintaining ductility.

2. Explain the difference between a universal mill and a tandem mill?

Universal Mill

- Processes metal strips or plates

- Vertical rollers apply pressure from both sides simultaneously

- Produces wide, flat products with uniform thickness

Tandem Mill

- Series of individual rolling stands arranged in sequence

- Metal passes through each stand in succession

- Reduces thickness gradually, producing thinner and more precise products

3. What are the key parameters that affect the grain structure of rolled metal?

- Rolling temperature

- Rolling speed

- Amount of reduction per pass

- Chemical composition of the metal

- Heat treatment after rolling

4. How do you optimize the rolling process to achieve specific mechanical properties in the final product?

- Control rolling temperature and cooling rates

- Adjust rolling speed and reduction per pass

- Employ appropriate lubrication to reduce friction

- Consider the metal’s alloy composition and heat treatment options

5. What are the different types of surface treatments used for rolled metal products?

- Electroplating

- Hot-dip galvanizing

- Anodizing

- Powder coating

- Chemical etching

6. Describe the various types of edge conditions that can occur during rolling and how they can be controlled?

- Edge cracking: Caused by excessive reduction or improper lubrication

- Edge waviness: Occurs due to uneven rolling pressure or misalignment

- Edge camber: Results from non-uniform temperature distribution

- Edge trimming or slitting can be employed to correct edge conditions

7. Explain the role of tension leveling in the production of rolled metal products?

- Tension leveling involves applying tension to the metal strip while it is being rolled

- It helps remove residual stresses and flattens the metal

- Improves dimensional accuracy, reduces camber, and enhances surface finish

8. How do you maintain the accuracy of rolling equipment and ensure consistent product quality?

- Regular calibration and maintenance of mill equipment

- Monitoring and controlling rolling parameters such as temperature, speed, and pressure

- Utilizing automated control systems to minimize variations

- Implementing statistical process controls to track and analyze quality data

9. Discuss the environmental considerations related to the rolling process and how they can be addressed?

- Reducing energy consumption through process optimization

- Minimizing waste and scrap generation

- Treating and recycling rolling fluids and lubricants

- Complying with environmental regulations and certifications

10. Describe emerging trends and advancements in the field of metal rolling?

- Development of high-strength, lightweight alloys

- Laser-assisted rolling techniques for precision forming

- Automated defect detection and quality monitoring systems

- Sustainable rolling practices and energy efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stem Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stem Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stem Roller plays a crucial role in the production of steel by operating a specially designed machine called a stem roller, which is used to roll and shape hot steel bars. Their primary responsibilities include:

1. Operating and Maintaining the Stem Roller

The Stem Roller is responsible for operating the stem roller machine safely and efficiently. This involves:

- Setting up and adjusting the machine according to the required specifications.

- Feeding hot steel bars into the machine and guiding them through the rollers.

- Monitoring the rolling process and making necessary adjustments to ensure the bars are rolled to the desired shape and dimensions.

- Maintaining the machine, including regular cleaning, lubrication, and troubleshooting any technical issues.

2. Handling and Inspecting Steel Bars

The Stem Roller is also responsible for handling and inspecting the steel bars before and after rolling. This involves:

- Inspecting the steel bars for defects or damage before feeding them into the machine.

- Checking the finished bars for quality, accuracy, and compliance with specifications.

- Identifying and segregating defective bars and reporting any quality issues to the supervisor.

3. Maintaining a Safe and Clean Work Environment

The Stem Roller is responsible for maintaining a safe and clean work environment. This involves:

- Following all safety protocols and wearing appropriate protective gear.

- Keeping the work area clean and free of hazards.

- Reporting any safety concerns or potential hazards to the supervisor.

4. Collaborating with Team Members

The Stem Roller works as part of a team and is responsible for collaborating with other team members. This involves:

- Communicating effectively with other team members to ensure smooth operation.

- Assisting other team members with tasks as needed.

- Participating in team meetings and contributing to discussions.

Interview Tips

Preparing thoroughly for a Stem Roller interview is essential to increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Researching the company and the specific role provides you with valuable information to demonstrate your knowledge and interest. Learn about the company’s history, products/services, industry standing, and the role’s responsibilities and requirements.

2. Practice Common Interview Questions

Practice answering common interview questions related to the role and industry. Prepare concise and well-structured responses that highlight your skills and experience. Consider using the STAR (Situation, Task, Action, Result) method to present your answers effectively.

3. Highlight Relevant Skills and Experience

Identify the key skills and experience required for the role and emphasize how your background aligns with these requirements. Showcase your technical abilities, such as operating stem rollers and handling steel bars, as well as your safety awareness and teamwork skills.

4. Prepare Industry-Specific Questions

Demonstrate your industry knowledge by preparing questions related to the steel production process, stem rolling techniques, or industry trends. Asking insightful questions shows your enthusiasm and engagement with the field.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for the interview on time to show respect for the interviewer and the company. Maintain a positive and confident attitude throughout the interview.

6. Follow Up After the Interview

After the interview, send a thank-you email to the interviewer, restating your interest in the role and reiterating your key skills and qualifications. This follow-up shows your gratitude and continued enthusiasm.

Next Step:

Now that you’re armed with the knowledge of Stem Roller interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stem Roller positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini