Are you gearing up for a career in Tubular Stock Glass Bulb Machine Former? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tubular Stock Glass Bulb Machine Former and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

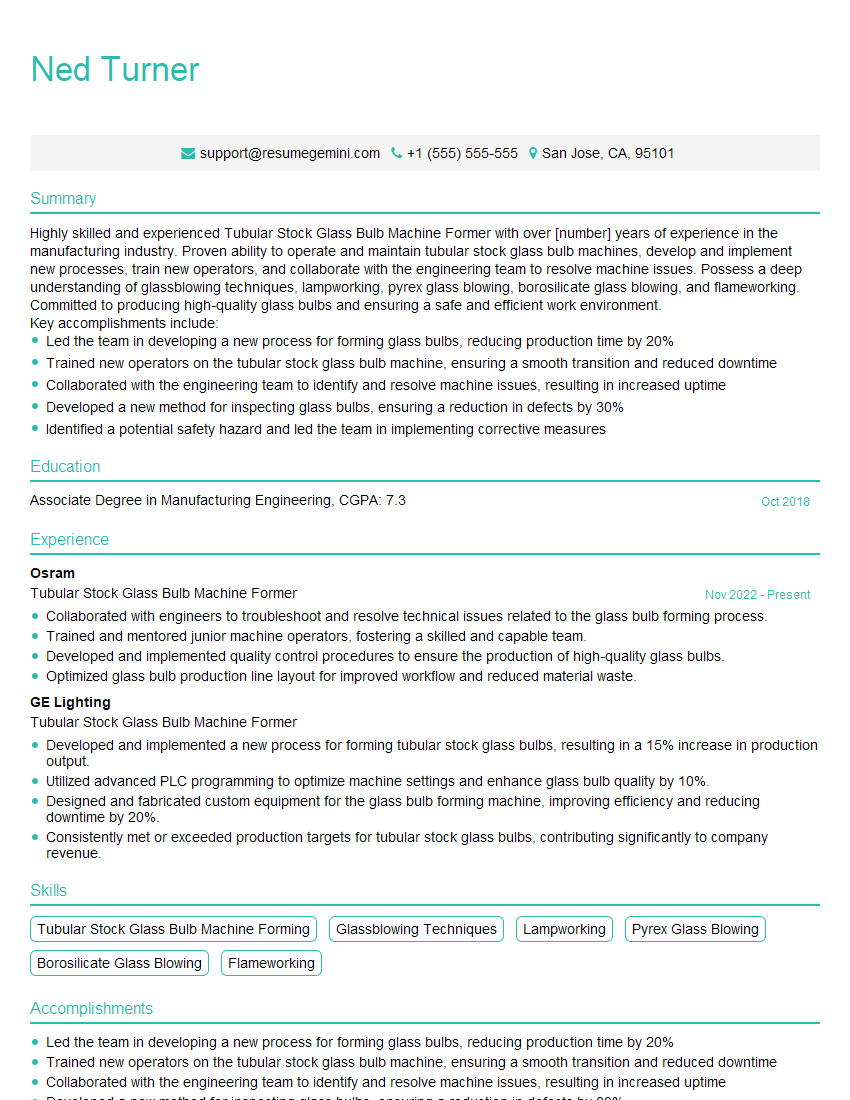

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tubular Stock Glass Bulb Machine Former

1. How do you adjust the temperature of the glass tube during the forming process?

To adjust the temperature of the glass tube during the forming process, I follow a specific procedure:

- I monitor the temperature of the glass tube using pyrometers or thermocouples.

- If the temperature deviates from the desired range, I adjust the heating burners accordingly.

- By increasing or decreasing the gas flow to the burners, I control the heat intensity and maintain the optimal temperature for forming.

- I continuously monitor the temperature and make fine adjustments as needed to ensure the glass tube is formable and meets the required specifications.

2. Describe the different types of molds used in tubular glass bulb forming and their applications.

Single-piece molds:

- Used for simple bulb shapes, such as round or oval.

- Provide a one-step forming process, reducing cycle time.

Two-piece molds:

- Used for more complex bulb shapes with defined necks or shoulders.

- Allow for greater control over the bulb’s geometry.

Multi-piece molds:

- Used for intricate bulb shapes with multiple cavities or sections.

- Enable the forming of bulbs with precise dimensions and complex features.

Transfer molds:

- Used in conjunction with other molds to form bulbs with varying diameters or shapes.

- Allow for seamless transitions between different sections of the bulb.

3. How do you troubleshoot common defects in tubular glass bulbs, such as blisters, cords, and striations?

To troubleshoot common defects in tubular glass bulbs, I employ the following strategies:

- Blisters: Inspect the glass tube for impurities, such as water or air bubbles, and eliminate them by degassing or using a vacuum chamber.

- Cords: Identify the source of the impurities causing the cords, such as contaminants in the glass batch or irregularities in the forming process, and address the issue.

- Striations: Evaluate the temperature distribution during forming and make adjustments to ensure uniform heating and cooling, minimizing thermal stresses that lead to striations.

4. Explain how you maintain and calibrate the forming machine to ensure precision and consistency.

To maintain and calibrate the forming machine, I adhere to the following practices:

- Regular maintenance: Perform routine inspections of the machine’s components, such as the molds, heating elements, and control systems, and address any issues promptly.

- Calibration: Use precision measuring instruments to verify the accuracy of the machine’s settings and make adjustments as needed.

- Data logging: Record machine parameters and forming data to monitor performance and identify any deviations from the desired specifications.

5. How do you ensure the quality of the finished glass bulbs and meet customer specifications?

To ensure the quality of the finished glass bulbs and meet customer specifications, I follow a comprehensive approach:

- In-process inspections: Conduct regular inspections during the forming process to identify and correct any potential defects.

- Final inspection: Perform thorough inspections of the finished bulbs, checking for dimensional accuracy, surface quality, and compliance with customer requirements.

- Statistical process control: Use statistical methods to monitor the production process and identify any areas for improvement.

6. Describe the safety precautions you observe while operating the tubular glass bulb forming machine.

To ensure a safe work environment, I adhere to the following safety precautions:

- Personal protective equipment: Wear appropriate protective gear, such as safety glasses, gloves, and earplugs, to minimize exposure to hazards.

- Machine guarding: Inspect and maintain machine guards to prevent access to moving parts or hot surfaces.

- Emergency procedures: Familiarize myself with emergency procedures and know how to respond to potential incidents, such as glass breakage or fire.

- Housekeeping: Maintain a clean and organized work area to prevent tripping or other accidents.

7. How do you handle situations where the forming machine experiences unexpected downtime or breakdowns?

In the event of unexpected downtime or breakdowns, I take the following steps:

- Identify the issue: Determine the root cause of the problem through troubleshooting.

- Repair or replace: Perform necessary repairs or replace faulty components to restore the machine to working order.

- Communicate: Inform the appropriate personnel, such as supervisors or maintenance technicians, about the issue and any potential delays.

- Minimize impact: Implement measures to minimize the impact of downtime on production, such as adjusting schedules or utilizing backup equipment.

8. Explain the role of automation in tubular glass bulb forming and its benefits.

Automation plays a crucial role in tubular glass bulb forming by:

- Increased efficiency: Automating repetitive tasks, such as loading and unloading the machine, reduces labor costs and improves throughput.

- Improved accuracy: Automated systems use precise control mechanisms to maintain consistent forming parameters, resulting in higher quality bulbs.

- Reduced waste: Automation helps reduce the number of defective bulbs by eliminating human error and ensuring optimal forming conditions.

- Enhanced safety: Automated machinery minimizes the risk of accidents by removing operators from hazardous areas.

9. How do you stay updated with the latest technological advancements in tubular glass bulb forming?

To stay updated with the latest technological advancements, I:

- Attend industry conferences and exhibitions: Participate in events where new technologies and trends are showcased.

- Read technical publications: Subscribe to industry journals and research papers to keep abreast of the latest developments.

- Network with peers: Connect with other professionals in the field to exchange knowledge and learn about innovative approaches.

- Explore vendor websites: Research the latest offerings from equipment manufacturers and solution providers.

10. How do you contribute to continuous improvement in the tubular glass bulb forming process?

I contribute to continuous improvement through:

- Process monitoring: Regularly track and analyze production data to identify areas for optimization.

- Collaboration: Work with colleagues, engineers, and supervisors to brainstorm ideas and develop innovative solutions.

- Experimentation: Conduct controlled experiments to test new techniques and materials, aiming to improve efficiency and quality.

- Feedback collection: Gather feedback from customers and colleagues to understand their needs and incorporate their suggestions into improvement initiatives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tubular Stock Glass Bulb Machine Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tubular Stock Glass Bulb Machine Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tubular Stock Glass Bulb Machine Formers are responsible for operating and maintaining machinery that shapes glass into tubular stock bulbs for various applications. Their key responsibilities include:

1. Machine Operation and Control

Operate tubular stock glass bulb machines to produce bulbs to required specifications.

- Set up and adjust machine parameters (e.g., speed, temperature, pressure).

- Monitor machine performance and make necessary adjustments to ensure smooth operation.

2. Quality Control and Inspection

Ensure the quality of produced bulbs meets standards.

- Visually inspect bulbs for defects or imperfections.

- Use measuring instruments to verify bulb dimensions and other specifications.

3. Machine Maintenance and Repair

Maintain and repair machinery regularly to prevent breakdowns and ensure optimal performance.

- Perform routine maintenance tasks (e.g., cleaning, lubrication, filter replacement).

- Troubleshoot and repair machine malfunctions using technical manuals and tools.

4. Collaboration and Communication

Work closely with other team members and supervisors to ensure smooth production processes.

- Receive instructions and communicate updates with supervisors and colleagues.

- Assist in training or guiding new employees.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Tubular Stock Glass Bulb Machine Former position:

1. Research the Company and Role

Demonstrate your interest and knowledge of the company and specific Tubular Stock Glass Bulb Machine Former role.

- Visit the company’s website to learn about their history, products, and values.

- Read the job description thoroughly and identify the key skills and responsibilities required.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize your relevant skills and experiences that align with the job requirements.

- Showcase your expertise in operating and maintaining glass-forming machinery.

- Highlight your ability to identify and resolve technical issues effectively.

- Emphasize your attention to detail and commitment to quality control.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that demonstrate your qualifications.

- Describe your experience in operating tubular stock glass bulb machines.

- Explain how you approach troubleshooting and resolving machine malfunctions.

- Discuss your quality control measures and how you ensure the bulbs meet specifications.

4. Ask Informed Questions

Asking well-informed questions during the interview shows your engagement and interest in the role and the company.

- Inquire about the company’s latest projects or developments in glass bulb technology.

- Ask about opportunities for professional development and growth within the organization.

- Seek clarification on any aspects of the role or the company that you may be curious about.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time to demonstrate your respect for the interviewers and the company.

- Opt for formal or business casual attire.

- Be punctual and allow yourself ample time to find the interview location and parking.

- Maintain a positive and confident demeanor throughout the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tubular Stock Glass Bulb Machine Former, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tubular Stock Glass Bulb Machine Former positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.