Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Charcoal Kiln Burner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Charcoal Kiln Burner so you can tailor your answers to impress potential employers.

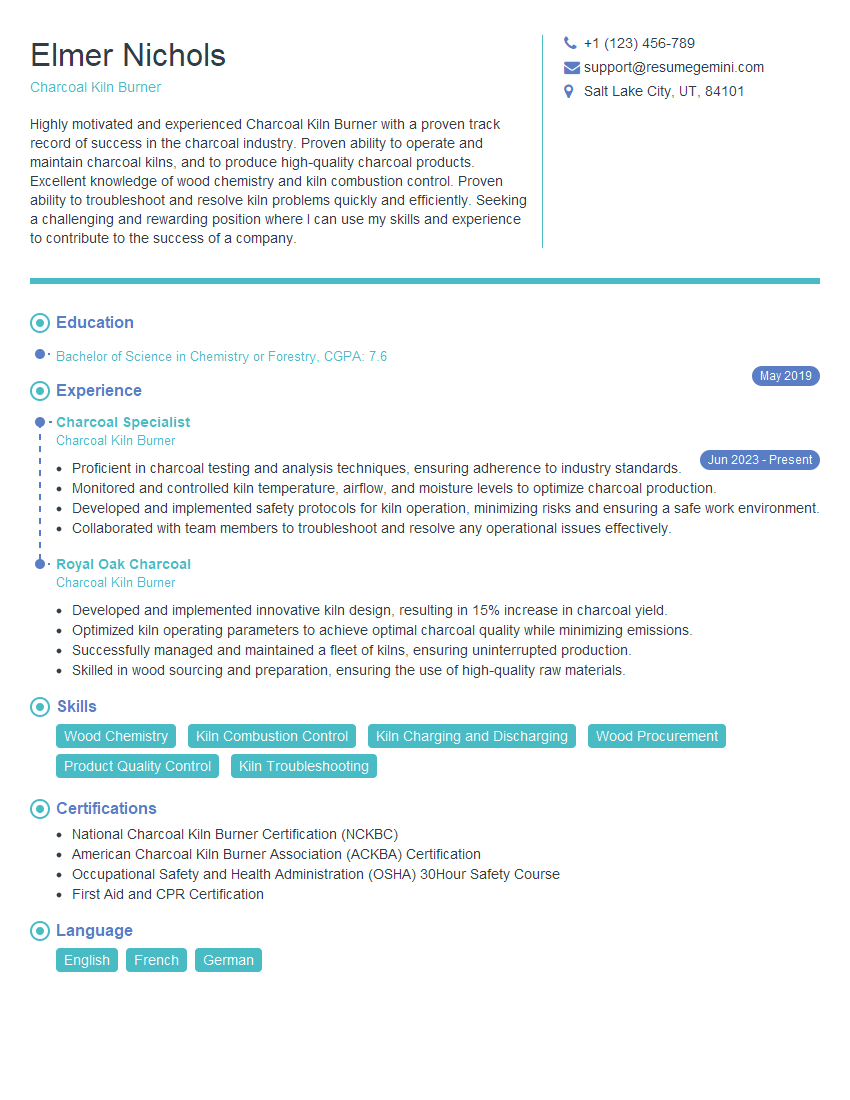

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Charcoal Kiln Burner

1. What are the key steps involved in operating a charcoal kiln?

The key steps involved in operating a charcoal kiln are:

- preparing the wood

- loading the kiln

- igniting the kiln

- regulating the airflow

- monitoring the temperature

- unloading the kiln

2. How do you control the airflow and temperature in a charcoal kiln?

Controlling Airflow

- The airflow in a charcoal kiln is controlled by adjusting the vents.

- The vents are usually located at the bottom and top of the kiln.

- Opening the vents allows more air to enter the kiln, which increases the combustion rate.

- Closing the vents restricts the airflow, which decreases the combustion rate.

Controlling Temperature

- The temperature in a charcoal kiln is controlled by regulating the airflow.

- A higher airflow will result in a higher temperature.

- A lower airflow will result in a lower temperature.

- The temperature should be monitored regularly to ensure that it is within the desired range.

3. What are the different types of charcoal kilns?

The different types of charcoal kilns are:

- earth kilns

- brick kilns

- metal kilns

4. What are the advantages and disadvantages of each type of charcoal kiln?

Earth Kilns

- Advantages:

- low cost to build

- easy to operate

- produce high-quality charcoal

- Disadvantages:

- low efficiency

- long production cycle

- can be difficult to control the temperature

Brick Kilns

- Advantages:

- higher efficiency than earth kilns

- shorter production cycle

- easier to control the temperature

- Disadvantages:

- more expensive to build than earth kilns

- require more maintenance

Metal Kilns

- Advantages:

- highest efficiency of all three types of kilns

- shortest production cycle

- most precise temperature control

- Disadvantages:

- most expensive to build of all three types of kilns

- require the most maintenance

5. What are the safety precautions that must be taken when operating a charcoal kiln?

The safety precautions that must be taken when operating a charcoal kiln are:

- wear appropriate safety gear, including gloves, safety glasses, and a hard hat

- keep the kiln area clear of combustible materials

- never leave the kiln unattended while it is in operation

- be aware of the potential for carbon monoxide poisoning and take appropriate precautions

- have a fire extinguisher nearby in case of emergency

6. How do you troubleshoot common problems that can occur when operating a charcoal kiln?

Some common problems that can occur when operating a charcoal kiln include:

- the kiln is not producing enough heat

- the kiln is producing too much smoke

- the charcoal is not burning evenly

- the kiln is leaking

Troubleshooting Tips

- If the kiln is not producing enough heat, check the airflow and make sure that the vents are open.

- If the kiln is producing too much smoke, check the airflow and make sure that the vents are closed.

- If the charcoal is not burning evenly, check the airflow and make sure that the vents are evenly distributed.

- If the kiln is leaking, check the seals and make sure that they are tight.

7. What are the quality standards for charcoal?

The quality standards for charcoal vary depending on the intended use.

- Charcoal used for cooking should be free of impurities, such as dirt, sand, and stones.

- Charcoal used for industrial applications should have a high carbon content and a low ash content.

8. How do you ensure that the charcoal produced meets the quality standards?

To ensure that the charcoal produced meets the quality standards, the following steps can be taken:

- use high-quality wood as the starting material

- control the airflow and temperature during the carbonization process

- test the charcoal to ensure that it meets the desired specifications

9. What are the environmental impacts of charcoal production?

The environmental impacts of charcoal production include:

- deforestation

- air pollution

- water pollution

- soil erosion

10. What are the sustainability practices that can be implemented to reduce the environmental impacts of charcoal production?

The sustainability practices that can be implemented to reduce the environmental impacts of charcoal production include:

- using sustainable forestry practices

- using efficient kilns

- recycling charcoal waste

- promoting the use of charcoal for cooking and industrial applications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Charcoal Kiln Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Charcoal Kiln Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Charcoal Kiln Burners are responsible for overseeing the operation of charcoal kilns, used for carbonizing wood and producing charcoal. Their primary duties include:

1. Kiln Preparation and Loading

Prepare kilns for use, ensuring they are clean, dry, and properly stacked with wood or other biomass.

- Inspect kilns for any damages or maintenance issues.

- Load kilns with wood according to specified proportions and densities.

2. Kiln Operation and Monitoring

Ignite kilns and monitor them closely throughout the carbonization process.

- Adjust temperature and airflow to optimize charcoal production and minimize waste.

- Monitor kiln readings and make adjustments as needed to ensure proper burning conditions.

3. Charcoal Extraction and Cooling

Unload charcoal from kilns once carbonization is complete and allow it to cool properly.

- Inspect charcoal quality and sort it into different grades based on size and purity.

- Package charcoal for storage or shipment.

4. Equipment Maintenance and Safety

Maintain and repair kiln equipment to ensure efficient operation and prevent accidents.

- Conduct regular inspections and repairs to prevent breakdowns and ensure safety.

- Follow safety protocols and use appropriate protective gear during kiln operation.

Interview Tips

To ace the interview for a Charcoal Kiln Burner position, candidates should prepare thoroughly and demonstrate their skills and knowledge. Here are some tips to help you succeed:

1. Research the Company and Industry

Gather information about the company’s history, operations, and reputation. Understand the charcoal industry, its trends, and environmental regulations.

- Visit the company’s website and social media platforms.

- Read industry publications and news articles.

2. Highlight Relevant Skills and Experience

Emphasize your experience in charcoal kiln operation, including loading, monitoring, and unloading kilns. Showcase your knowledge of kiln maintenance and safety procedures.

- Quantify your accomplishments using specific examples and metrics.

- Be prepared to discuss your ability to work independently and as part of a team.

3. Prepare for Technical Questions

Expect questions about kiln operation, temperature control, and charcoal quality. Prepare to discuss your understanding of the carbonization process and how to troubleshoot common problems.

- Study the basics of charcoal production and kiln technology.

- Practice answering technical questions clearly and concisely.

4. Showcase Your Safety Awareness

Charcoal kiln operation involves potential hazards. Highlight your commitment to safety protocols and your ability to identify and mitigate risks.

- Discuss your experience with safety equipment and hazard prevention measures.

- Be ready to explain how you would respond to emergency situations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Charcoal Kiln Burner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.