Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cupola Operator, Insulation interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cupola Operator, Insulation so you can tailor your answers to impress potential employers.

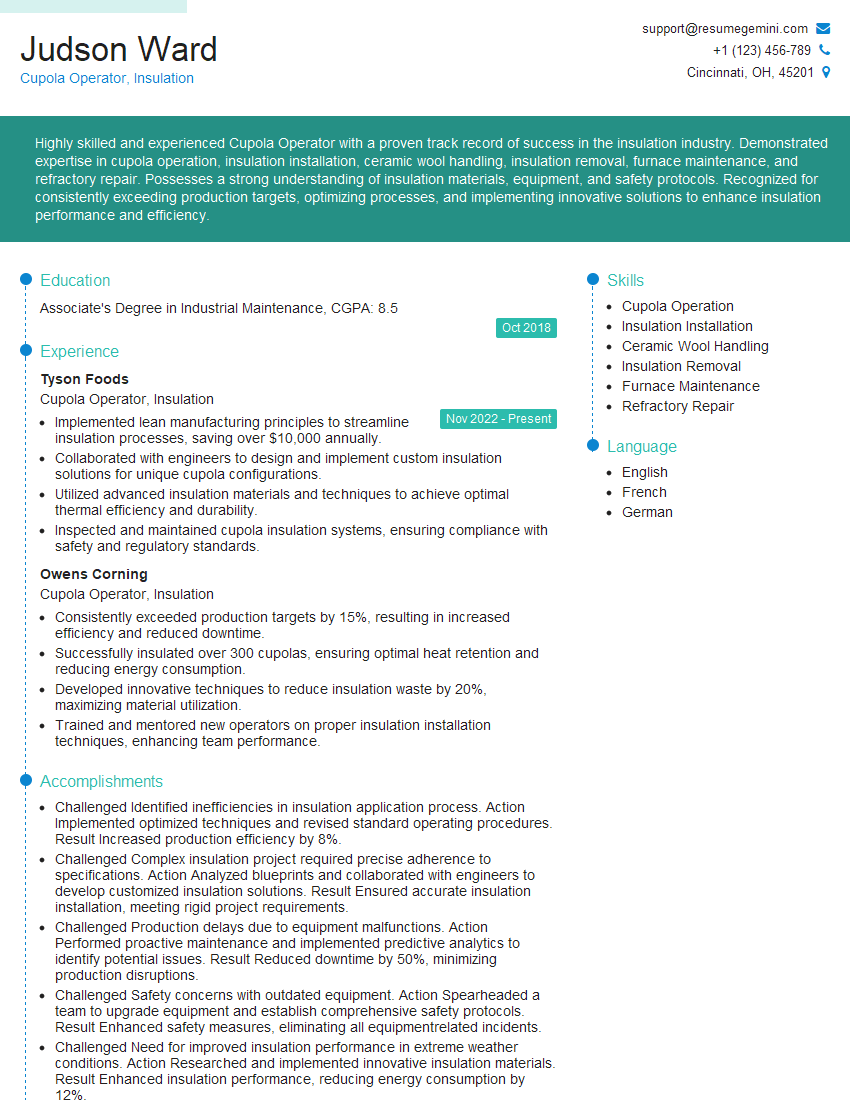

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Operator, Insulation

1. Describe the process of cupola operation, including charge preparation, melting, and tapping.

- Charge preparation: This involves gathering and weighing the raw materials, including iron scrap, coke, and limestone, to create the desired charge mix.

- Melting: The charge is loaded into the cupola and melted using a forced air blast. The molten metal is collected in a well at the bottom of the cupola.

- Tapping: The molten metal is tapped from the well into ladles and poured into molds or transported to other processes.

2. Explain the role of insulation in cupola operation and its impact on energy efficiency.

- Insulation reduces heat loss from the cupola, which improves energy efficiency.

- By maintaining a higher temperature inside the cupola, insulation helps to achieve a more consistent melt and reduce the formation of cold shuts.

- Proper insulation can extend the life of the cupola lining.

3. Describe the different types of insulation used in cupola applications and their respective advantages and disadvantages.

- Ceramic fiber: High thermal resistance, low density, and ease of installation. However, it can be fragile and susceptible to damage.

- Insulating firebrick: Good thermal resistance and durability. However, it can be more expensive and difficult to install.

- Castable refractory: Can be custom-shaped and poured into place. Provides excellent insulation and durability.

- Mineral wool: Lightweight and cost-effective. However, it can absorb moisture and lose its insulating properties.

4. How do you ensure the proper installation and maintenance of cupola insulation?

- Follow manufacturer’s specifications for installation, including proper thickness and density.

- Inspect insulation regularly for damage and replace as needed.

- Use a thermal camera to detect areas of heat loss and address insulation issues.

- Maintain proper air flow around the cupola to prevent overheating.

5. Explain the safety precautions that must be observed when working with cupola insulation materials, such as ceramic fiber.

- Wear appropriate personal protective equipment (PPE), including gloves, respirators, and protective clothing.

- Handle insulation materials with care to avoid creating dust.

- Avoid inhaling insulation fibers or dust.

- Store insulation materials in a dry and protected area.

6. Describe the environmental regulations and industry standards that apply to cupola insulation.

- OSHA regulations govern the handling and exposure to insulation materials.

- EPA regulations may apply to the disposal of insulation waste.

- ASTM standards provide guidelines for the performance and testing of insulation materials.

7. Discuss the role of insulation in reducing noise levels from cupola operations.

- Insulation can absorb and dampen sound waves, reducing noise levels.

- Proper insulation can create a quieter working environment and improve employee comfort.

- Sound-absorbing insulation can be applied to walls, ceilings, and other areas around the cupola.

8. Explain the use of thermal blankets in cupola insulation and their benefits.

- Thermal blankets are flexible insulation blankets that can be wrapped around the cupola.

- They provide additional insulation and reduce heat loss, especially during shutdowns or periods of low operation.

- Thermal blankets are easy to install and remove, allowing for quick access to the cupola for maintenance or repairs.

9. Describe the use of insulation in cupola preheaters and its impact on energy consumption.

- Insulation in preheaters reduces heat loss and improves preheating efficiency.

- By preheating the blast air, insulation helps to reduce fuel consumption and improve melt quality.

- Proper insulation can also extend the life of the preheater lining.

10. Discuss the importance of regular insulation inspections and maintenance for optimal cupola performance.

- Regular inspections help to identify any damage or deterioration of insulation.

- Timely maintenance, such as patching or replacing insulation, ensures optimal performance and energy efficiency.

- Proper insulation maintenance can prevent unexpected breakdowns and reduce overall operating costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Operator, Insulation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Operator, Insulation‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cupola Operators, Insulation, play a crucial role in the manufacturing process by operating and monitoring cupolas to produce insulation materials. Their key responsibilities include:

1. Cupola Operation

Operate cupolas, monitors temperature, and pressure to ensure efficient operation.

- Monitor and control cupola temperature and pressure using sensors and gauges.

- Adjust cupola operating parameters to optimize insulation production.

2. Insulation Production

Produce high-quality insulation materials according to specifications.

- Control the flow of raw materials into the cupola, ensuring the correct ratios for insulation production.

- Monitor the composition and properties of the molten insulation to meet quality standards.

3. Equipment Maintenance

Maintain and troubleshoot cupola and other equipment to ensure smooth operation.

- Inspect and maintain cupola components, such as refractory lining, burners, and instrumentation.

- Troubleshoot and repair equipment breakdowns, minimizing production downtime.

4. Safety Compliance

Adhere to all safety regulations and procedures to ensure a safe working environment.

- Follow established safety protocols related to cupola operation and insulation handling.

- Wear appropriate personal protective equipment (PPE), such as gloves, hard hats, and safety glasses.

Interview Preparation Tips

To ace your interview for a Cupola Operator, Insulation position, consider the following preparation tips:

1. Research the Company and Industry

Learn about the company’s history, values, and products. Research the industry to understand market trends and technological advancements in insulation production.

2. Practice Common Interview Questions

Prepare for questions about your experience, skills, and knowledge of cupola operation. Consider using the STAR method (Situation, Task, Action, Result) to answer questions effectively.

3. Highlight Your Technical Expertise

Emphasize your understanding of cupola operation, insulation production, and equipment maintenance. Provide specific examples of your involvement in these areas.

4. Demonstrate Safety Consciousness

Stress your commitment to safety by highlighting your knowledge of safety regulations and experience in following safety protocols. Explain how you prioritize safety in your work environment.

5. Show Your Communication and Teamwork Skills

Cupola Operators often work in teams and interact with various departments. Emphasize your ability to communicate effectively and collaborate with others.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cupola Operator, Insulation, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cupola Operator, Insulation positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.