Feeling lost in a sea of interview questions? Landed that dream interview for Dry Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dry Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

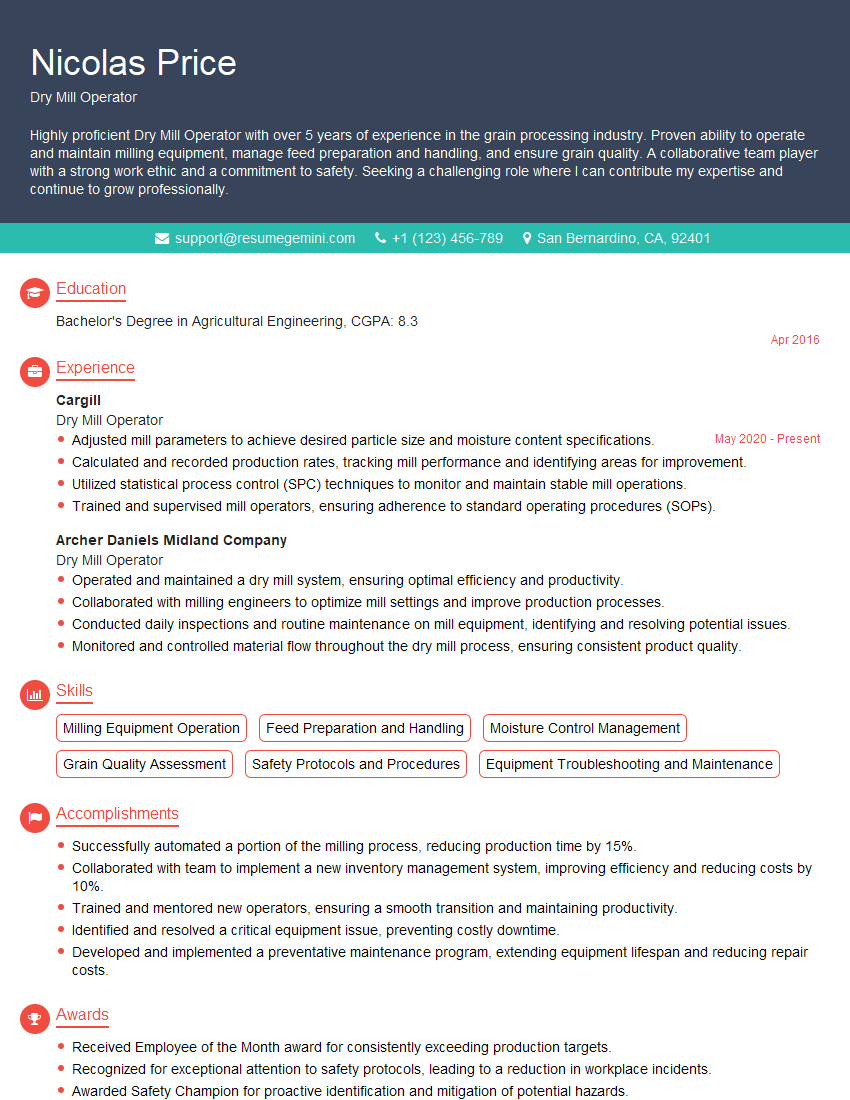

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Mill Operator

1. Explain the process of drying the grains in a dry mill?

The process of drying grains in a dry mill involves several steps:

- Cleaning: Grains are first cleaned to remove impurities such as dirt, stones, and chaff.

- Conditioning: Grains are then conditioned by adding moisture to make them more receptive to drying.

- Drying: Grains are passed through a dryer, which uses hot air to remove moisture and lower the moisture content.

- Cooling: After drying, grains are cooled to prevent over-drying and preserve their quality.

- Storage: Dried grains are then stored in silos or other storage facilities.

2. What are the different types of dryers used in dry mills and their advantages and disadvantages?

Continuous-flow dryers

- Advantages: High capacity, efficient, and cost-effective

- Disadvantages: Can be complex to operate and require specialized maintenance

Batch dryers

- Advantages: Simple to operate, versatile, and can handle different grain types

- Disadvantages: Lower capacity and may require longer drying times

Rotary dryers

- Advantages: Continuous operation, high capacity, and uniform drying

- Disadvantages: Can be expensive to purchase and maintain

3. What are the critical control points (CCPs) in a dry mill and how do you ensure they are met?

Critical control points in a dry mill include:

- Grain conditioning: Monitoring and controlling moisture levels to optimize drying efficiency

- Drying temperature: Maintaining the correct temperature to avoid over-drying or under-drying

- Cooling: Ensuring grains are adequately cooled to prevent spoilage

- Storage conditions: Controlling temperature, humidity, and ventilation to maintain grain quality

CCPs are met through regular monitoring, data logging, and corrective actions when necessary.

4. How do you maintain and calibrate the equipment used in a dry mill?

- Regular inspections: Visually inspecting equipment for wear and tear, leaks, and other issues

- Preventative maintenance: Performing scheduled maintenance tasks such as lubrication, filter cleaning, and sensor calibration

- Calibration: Using certified equipment and procedures to ensure accuracy of sensors and measuring devices

- Record keeping: Maintaining detailed records of maintenance activities and calibration results

5. What are the safety precautions that must be followed when working in a dry mill?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing

- Be aware of potential hazards such as moving machinery, hot surfaces, and dust

- Follow established safety protocols for handling chemicals and hazardous materials

- Maintain a clean and organized work area

- Report any unsafe conditions or incidents immediately

6. How do you optimize the drying process to achieve the desired moisture content and quality?

Optimizing the drying process involves:

- Monitoring moisture levels: Regularly checking grain moisture content to ensure it meets specifications

- Adjusting drying parameters: Modifying temperature, air flow rate, and drying time based on moisture readings

- Grain blending: Mixing grains with different moisture contents to reach the desired average moisture

- Using moisture conditioning agents: Adding agents such as steam or water to grains to facilitate drying

7. How do you troubleshoot common problems that occur during the drying process?

- Over-drying: Adjusting drying parameters, increasing air flow, or reducing drying time

- Under-drying: Increasing drying temperature, slowing air flow, or extending drying time

- Uneven drying: Mixing grains, adjusting air distribution, or using baffles to ensure uniform airflow

- Equipment malfunctions: Identifying and repairing faulty sensors, motors, or other equipment

8. What are the quality control measures implemented in a dry mill to ensure the quality of the dried grains?

- Grain inspection: Regularly inspecting grains for quality defects such as discoloration, damage, or foreign objects

- Moisture testing: Using moisture meters to ensure dried grains meet moisture specifications

- Sensory evaluation: Assessing grain appearance, odor, and texture to evaluate quality

- Microbiological testing: Testing grains for the presence of bacteria, mold, or other microorganisms

9. How do you stay up to date with the latest technologies and advancements in dry milling?

- Attending industry conferences and trade shows

- Reading technical journals and articles

- Consulting with industry experts and equipment manufacturers

- Participating in training and development programs

10. How would you handle a situation where there is a sudden increase in demand for dried grains and you need to meet the demand efficiently?

To handle increased demand for dried grains, I would:

- Assess the situation: Determine the extent of the increase and the available resources

- Optimize the drying process: Review current drying parameters and make necessary adjustments to increase capacity

- Increase staffing: If needed, hire additional personnel or adjust work schedules to meet the demand

- Monitor progress: Closely monitor the drying process and make adjustments as necessary to ensure quality and efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Mill Operators play a crucial role in the grain processing industry, overseeing the operation and maintenance of dry milling equipment to produce various grain-based products.

1. Operating and Monitoring Dry Milling Equipment

The primary responsibility of a Dry Mill Operator is to operate and monitor dry milling equipment, including grinders, sifters, and conveyors. They ensure that the equipment is functioning optimally and make adjustments as needed to maintain consistent product quality and efficiency.

- Operate and monitor grinders to crush grain into various sizes and textures.

- Control sifters to separate crushed grain into different grades and fractions.

2. Maintaining and Troubleshooting Equipment

Dry Mill Operators are responsible for maintaining and troubleshooting dry milling equipment to prevent breakdowns and ensure smooth operations. They perform regular inspections, lubricate equipment, and make necessary repairs or adjustments.

- Inspect equipment regularly for wear and tear, and make necessary adjustments or repairs.

- Troubleshoot equipment malfunctions and take corrective actions to resolve issues.

3. Quality Control and Product Testing

Dry Mill Operators play a vital role in ensuring the quality of dry milled products. They perform quality control tests and monitor product specifications to meet customer requirements.

- Conduct quality control tests to ensure that dry milled products meet specifications for moisture content, particle size, and other parameters.

- Monitor product samples and make adjustments to equipment settings to maintain consistent quality.

4. Safety and Compliance

Dry Mill Operators are responsible for maintaining a safe and compliant work environment. They adhere to safety regulations, follow established procedures, and ensure that equipment is operated in accordance with safety protocols.

- Comply with all safety regulations and guidelines.

- Maintain a clean and organized work area.

Interview Tips

To ace the interview for a Dry Mill Operator position, it is essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you make a positive impression:

1. Research the Company and IndustryIt is important to research the company you are applying to and the dry milling industry in general. This will demonstrate your interest in the position and give you a better understanding of their operations.

2. Highlight Your Technical SkillsEmphasize your technical skills related to dry milling equipment operation, maintenance, and troubleshooting. Provide specific examples of your experience and how you have successfully resolved issues.

3. Showcase Your Quality Control ExperienceHighlight your experience in quality control and product testing. Explain how you have ensured product quality and met customer specifications in previous roles.

4. Emphasize Your Safety AwarenessDemonstrate your understanding of safety protocols and compliance requirements in the dry milling industry. Share examples of how you have prioritized safety in your work.

5. Be Prepared for Behavioral QuestionsPrepare for behavioral questions that may be asked during the interview. Use the STAR method (Situation, Task, Action, Result) to answer these questions and provide specific examples of your work experience.

6. Practice Your Communication SkillsPractice your communication skills to ensure that you can convey your ideas and answer questions clearly and effectively. Be confident and articulate during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.