Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Flat Drier position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

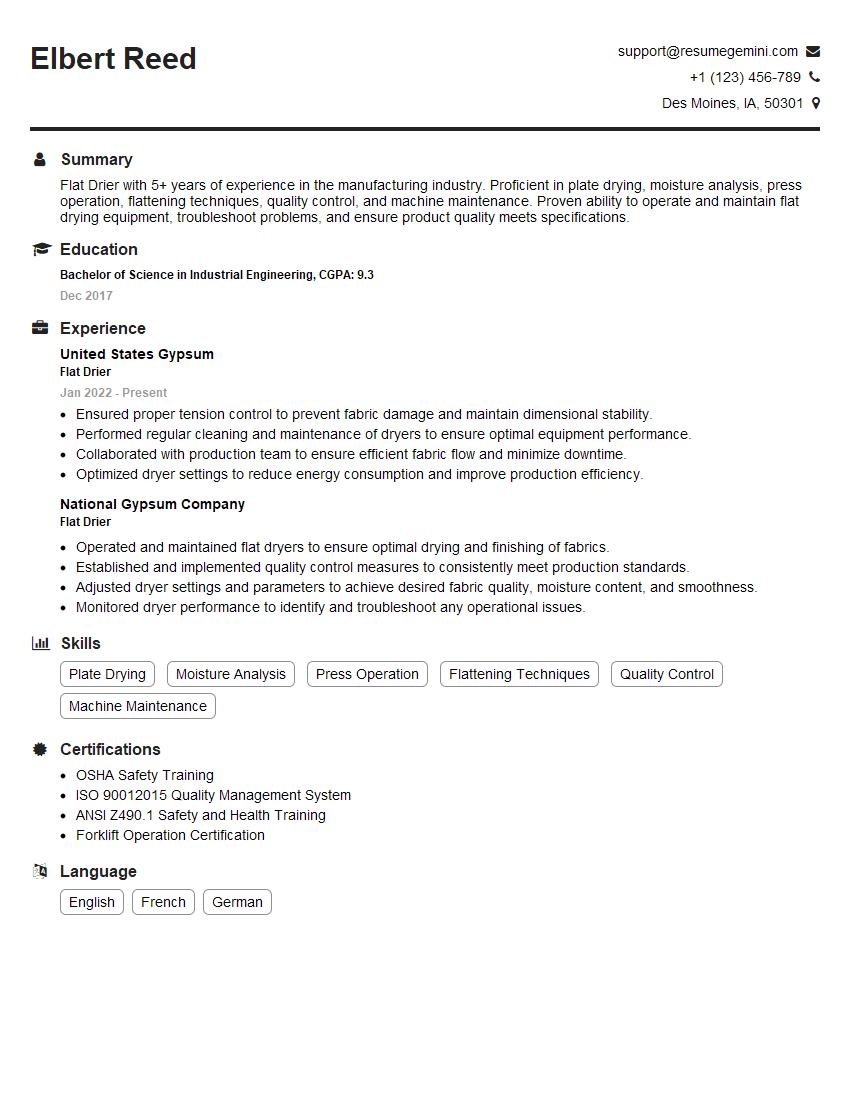

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flat Drier

1. What are the different types of flat dryers, and what are their advantages and disadvantages?

There are two main types of flat dryers: batch dryers and continuous dryers.

- Batch dryers are used to dry small batches of material. They are typically used in laboratory or pilot plant settings. The advantages of batch dryers include their simplicity and flexibility. However, batch dryers can be slow and inefficient.

- Continuous dryers are used to dry large volumes of material. They are typically used in industrial settings. The advantages of continuous dryers include their high efficiency and productivity. However, continuous dryers can be more complex and expensive than batch dryers.

2. What are the key factors to consider when selecting a flat dryer?

- The type of material to be dried

- The desired moisture content of the dried material

- The capacity of the dryer

- The energy efficiency of the dryer

- The cost of the dryer

3. What are the common problems associated with flat dryers, and how can they be solved?

The most common problems associated with flat dryers include:

- Over-drying, which can damage the material being dried

- Under-drying, which can leave the material too wet

- Uneven drying, which can result in inconsistencies in the quality of the dried material

These problems can be solved by carefully controlling the drying process. This includes monitoring the temperature, humidity, and airflow in the dryer. It also involves adjusting the speed of the dryer conveyor belt and the thickness of the material being dried.

4. What are the safety precautions that should be taken when operating a flat dryer?

- Never operate a flat dryer without first reading and understanding the manufacturer’s instructions.

- Always wear appropriate safety gear, such as gloves, safety glasses, and a lab coat.

- Keep the dryer area clean and free of debris.

- Never overload the dryer.

- Do not attempt to repair the dryer yourself. If the dryer malfunctions, contact a qualified technician.

5. What are the maintenance procedures that should be performed on a flat dryer?

- Regularly clean the dryer, including the conveyor belt, heating elements, and fans.

- Inspect the dryer for any signs of damage or wear and tear.

- Lubricate the dryer’s moving parts as needed.

- Calibrate the dryer’s temperature and humidity controls.

6. What are the different types of materials that can be dried using a flat dryer?

- Paper

- Textiles

- Food

- Chemicals

- Pharmaceuticals

7. What are the environmental regulations that apply to the operation of flat dryers?

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

8. What are the industry standards for the operation of flat dryers?

- ANSI/AMCA Standard 210-07

- NFPA Standard 86

- ASTM Standard E104

9. What are the emerging trends in flat dryer technology?

- The use of energy-efficient technologies

- The development of new materials for dryer construction

- The integration of automation and control systems

10. What are the career opportunities for flat dryer operators?

- Flat dryer operators can work in a variety of industries, including the paper, textile, food, chemical, and pharmaceutical industries.

- Flat dryer operators can advance to positions such as supervisor, manager, or engineer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flat Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flat Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flat Driers are responsible for overseeing the drying and finishing processes of flat glass, ensuring the production of high-quality glass products. Their primary duties involve:

1. Monitoring and Controlling Drying Process

Flat Driers monitor the drying process of flat glass, adjusting temperature, humidity, and air flow to achieve optimal drying conditions. They also ensure that the glass is dried evenly to prevent warping or distortion.

- Maintaining precise temperature and humidity levels within the dryer to prevent defects.

- Adjusting air flow and exhaust systems to optimize drying efficiency.

2. Ensuring Glass Quality

Flat Driers inspect the dried glass for any defects or imperfections, such as scratches, chips, or bubbles. They also conduct thickness measurements to ensure that the glass meets specifications.

- Inspecting glass surfaces for defects using visual inspection techniques.

- Measuring glass thickness using precision measuring instruments.

3. Maintaining and Troubleshooting Equipment

Flat Driers are responsible for maintaining and troubleshooting the drying equipment. They perform regular maintenance tasks, such as cleaning and lubrication, to prevent breakdowns and ensure optimal performance.

- Performing routine maintenance and repairs on drying equipment.

- Troubleshooting equipment malfunctions and implementing corrective actions.

4. Adhering to Safety Regulations

Flat Driers prioritize safety in the workplace, adhering to established safety regulations and procedures. They wear appropriate safety gear and follow safe work practices to minimize risks associated with handling and drying glass.

- Following established safety protocols and guidelines.

- Utilizing proper personal protective equipment (PPE) to prevent injuries.

Interview Tips

To ace an interview for a Flat Drier position, it is essential to thoroughly prepare and showcase your relevant skills and experience. Here are some helpful tips:

1. Research the Company and Industry

Familiarize yourself with the glass industry and the company you are applying to. Learn about their products, processes, and market position. This knowledge will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on trends.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in glass drying and finishing. Quantify your accomplishments and provide specific examples that showcase your abilities. Highlight any experience in quality control, equipment maintenance, or safety protocols.

- Describe your experience in monitoring and controlling drying processes.

- Share examples of your problem-solving abilities in troubleshooting equipment.

3. Prepare for Technical Questions

Expect to answer technical questions about the drying process, glass quality standards, and equipment maintenance. Prepare by reviewing the basics of flat glass drying, common defects, and troubleshooting techniques.

- Research different drying methods and their applications.

- Study the common types of defects in flat glass and their causes.

4. Demonstrate Attention to Detail and Safety

Flat Driers require meticulous attention to detail and a strong focus on safety. Highlight your ability to inspect glass thoroughly for defects and your adherence to safety regulations. Provide examples of how you have maintained a safe work environment.

- Describe your quality control procedures and how you ensure accuracy.

- Explain your understanding of workplace safety protocols and how you prioritize safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flat Drier interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.