Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flash Drier Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flash Drier Operator so you can tailor your answers to impress potential employers.

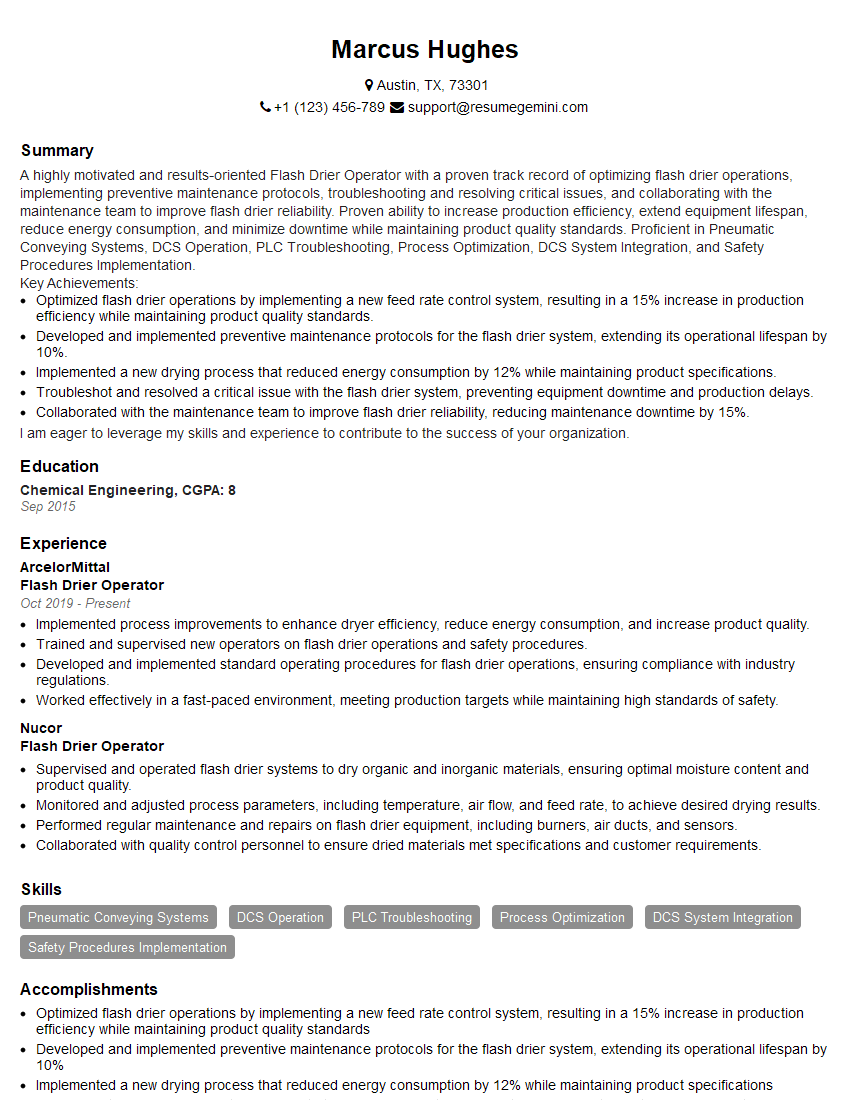

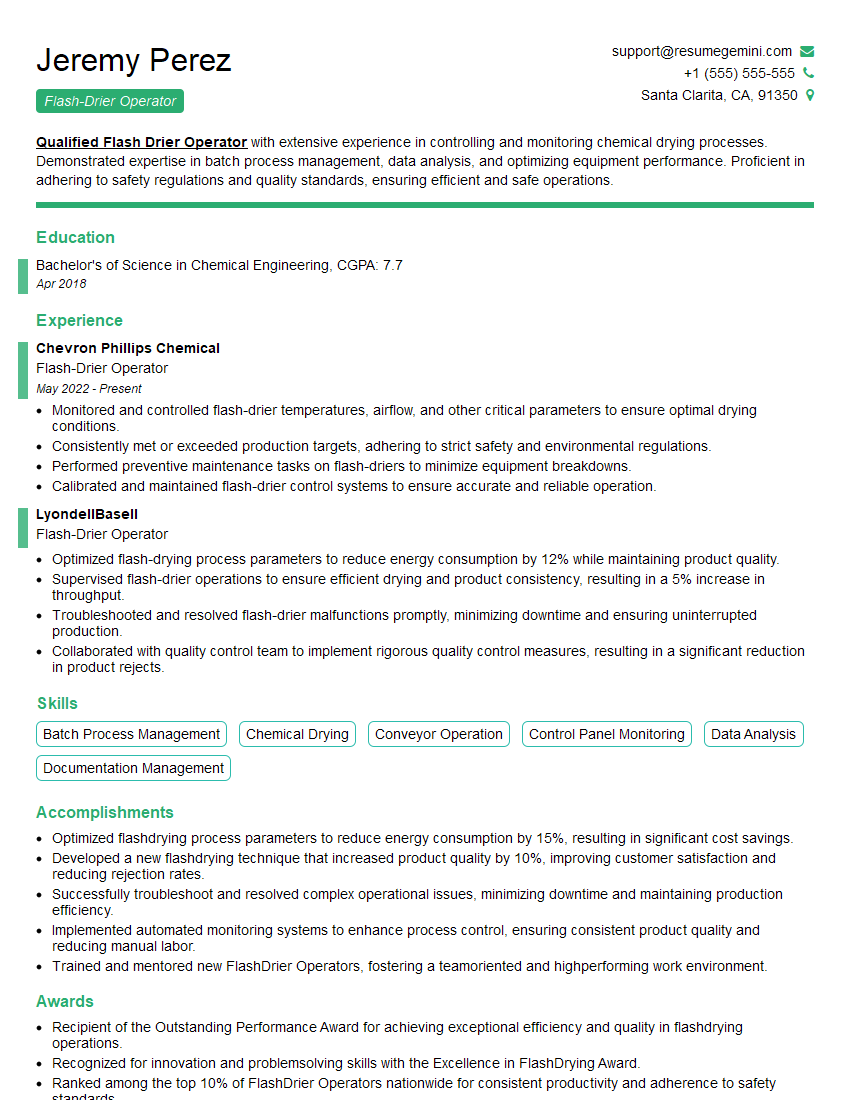

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flash Drier Operator

1. Explain the role of a flash drier in an industrial setting?

A flash drier is a type of industrial drying equipment used to rapidly remove moisture from materials using hot air. It is commonly employed in various industries for applications like drying of food products, pharmaceuticals, chemicals, and minerals.

2. Describe the key components of a flash drier and their functions?

- Hot air generator: Produces hot air using burners or other heat sources.

- Drying chamber: Where the material is contacted with hot air to evaporate moisture.

- Feed system: Conveys the material into the drying chamber.

- Exhaust system: Removes moist air from the drying chamber.

- Material discharge system: Transports the dried material out of the chamber.

3. What are the factors that affect the drying efficiency of a flash drier?

- Temperature of the hot air

- Flow rate of the hot air

- Size and shape of the material particles

- Moisture content of the material

- Residence time of the material in the drying chamber

4. How do you monitor and control the operation of a flash drier to ensure optimal performance?

- Monitor temperatures at various points in the system.

- Control airflow rates to maintain desired drying conditions.

- Adjust feed rates to optimize material flow.

- Inspect equipment regularly to identify potential issues.

- Perform regular maintenance and troubleshooting.

5. What safety precautions should be taken when operating a flash drier?

- Wear appropriate personal protective equipment.

- Ensure proper ventilation to prevent accumulation of hazardous gases.

- Follow established operating procedures.

- Be aware of potential fire and explosion risks.

- Receive proper training and certification.

6. Describe the maintenance procedures for a flash drier, including preventive measures?

- Regular cleaning of the drying chamber and components.

- Inspection and replacement of worn or damaged parts.

- Lubrication of moving components.

- Calibration of temperature and flow sensors.

- Preventive measures include monitoring equipment performance, identifying potential issues early, and scheduling maintenance accordingly.

7. What troubleshooting steps would you take if the flash drier is not drying the material effectively?

- Check temperatures and airflow rates to ensure they meet specifications.

- Inspect the material feed system for any blockages or issues.

- Examine the exhaust system to ensure proper air removal.

- Verify that the material is not overloaded or underloaded in the drying chamber.

- Consider the possibility of material contamination or changes in material properties.

8. How do you optimize the energy efficiency of a flash drier?

- Use energy-efficient hot air generators.

- Optimize airflow rates to minimize energy consumption.

- Insulate the drying chamber to reduce heat loss.

- Consider using waste heat from other processes.

- Implement process control measures to avoid over-drying.

9. Describe your experience in operating and maintaining flash driers?

(Provide details of previous experiences, including specific equipment models, industry applications, and responsibilities.)

10. Are you familiar with any industry standards or regulations related to the operation of flash driers?

- (Mention relevant standards, such as those from ASME, NFPA, or OSHA)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flash Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flash Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flash Drier Operators play a vital role in ensuring the efficient and safe operation of flash driers, which are commonly used in the chemical, food processing, and mining industries. Their key responsibilities include:

1. Monitor and Control Operation

Continuously monitor all aspects of the flash drier’s operation, including temperature, pressure, and airflow rates. Adjust settings as necessary to maintain optimal operating conditions.

- Monitor and adjust temperature, pressure, and airflow to ensure product quality and process efficiency.

- Start and stop the drier, and monitor the operation of all associated equipment.

2. Maintain and Inspect Equipment

Regularly inspect and maintain the flash drier and associated equipment, including fans, motors, and instrumentation. Perform routine maintenance tasks such as cleaning, lubrication, and minor repairs.

- Perform routine maintenance and repairs on the drier and related equipment, such as fans, motors, and instrumentation.

- Inspect the drier for any signs of wear or damage, and report any issues to the supervisor.

3. Handle Materials

Load and unload feed materials into and out of the flash drier. Ensure that the materials are handled in a safe and efficient manner.

- Control the flow of materials through the drier, ensuring a consistent product quality.

- Operate material handling equipment, such as conveyors and feeders.

4. Quality Control

Test and evaluate the quality of the dried product. Ensure that the product meets the required specifications.

- Conduct quality control tests on the dried product, such as moisture content and particle size.

- Provide feedback to the supervisor on product quality and any necessary adjustments to the process.

5. Safety and Compliance

Follow all safety procedures and regulations. Maintain a clean and safe work area.

- Follow all safety protocols and regulations, including wearing appropriate personal protective equipment.

- Respond to emergencies and spills immediately, and ensure the safety of the work area.

Interview Tips

To ace the interview for a Flash Drier Operator position, it is essential to prepare thoroughly and demonstrate your knowledge and skills. Here are some tips to help you succeed:

1. Research the Company and Industry

Research the specific company you are applying to, as well as the flash drying industry. This will give you a good understanding of the company culture, its products or services, and the current trends and challenges in the industry.

- Visit the company website and social media pages.

- Explore industry news and publications.

- Identify common industry terms and processes.

2. Practice Answering Common Interview Questions

Practice answering common interview questions related to your experience, skills, and the job requirements. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Explain your previous experience operating flash driers or similar equipment.

- Describe your troubleshooting and problem-solving skills.

- Discuss your commitment to safety and compliance.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge of flash drying processes. Be prepared to discuss the different types of flash driers, their components, and how they operate.

- Understand the principles of heat transfer and fluid dynamics.

- Demonstrate proficiency in process control and instrumentation.

- Be familiar with different materials and their drying characteristics.

4. Demonstrate Your Problem-Solving Abilities

Flash Drier Operators often face unexpected challenges. In the interview, highlight your problem-solving abilities and provide examples of how you have successfully resolved issues.

- Discuss a situation where you identified and resolved a problem with the flash drier.

- Explain your approach to troubleshooting and finding effective solutions.

- Emphasize your teamwork and communication skills.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions about the company, the role, or the industry to demonstrate your enthusiasm and curiosity.

- Inquire about the company’s growth plans.

- Ask about the challenges and opportunities associated with the role.

- Seek information about the company’s commitment to training and development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flash Drier Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.