Are you gearing up for an interview for a Glass Furnace Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Furnace Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

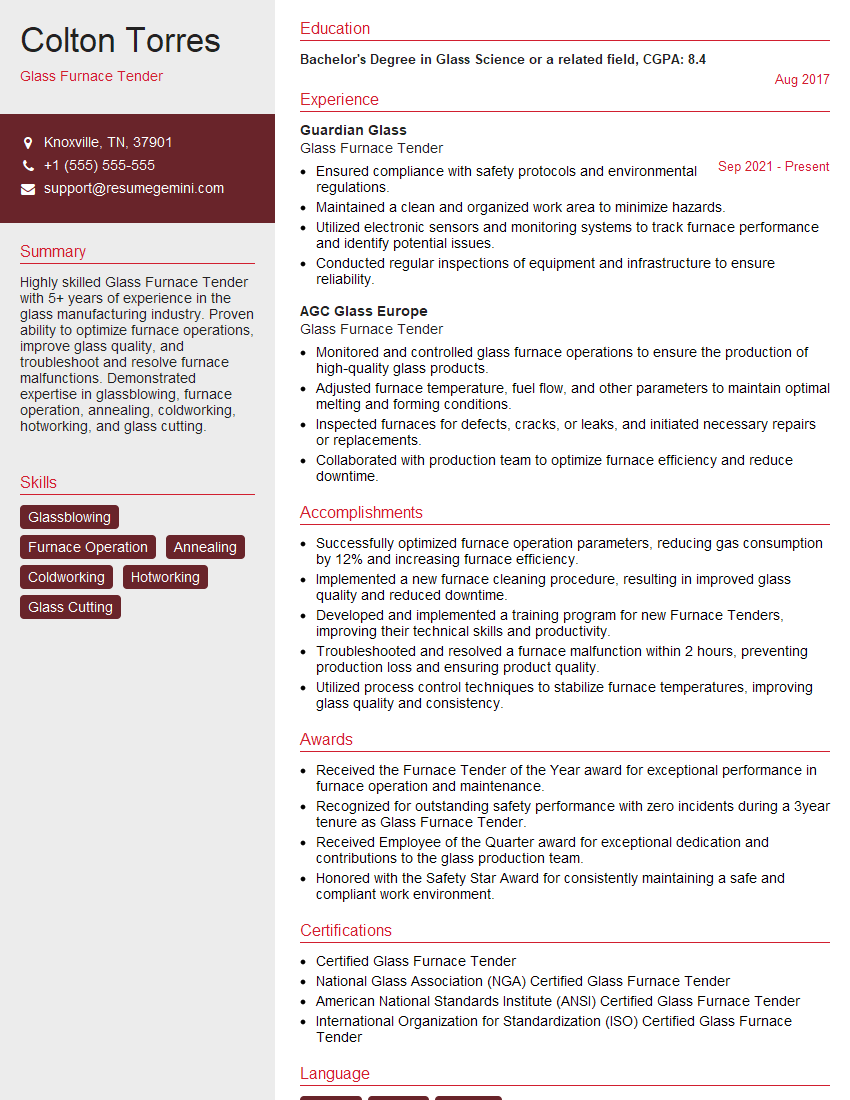

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Furnace Tender

1. Explain the process of melting glass in a furnace?

The process of melting glass in a furnace involves several stages:

- Batch Preparation: Raw materials (e.g., sand, soda ash, limestone) are weighed and mixed to form a batch.

- Melting: The batch is heated in a furnace to a temperature between 1400-1600°C, causing the materials to melt and form a molten glass.

- Fining: Bubbles and impurities are removed from the molten glass through the addition of fining agents.

- Homogenization: The molten glass is stirred to ensure uniformity in composition and temperature.

- Annealing: The molten glass is slowly cooled to reduce stress and improve its strength and durability.

2. What are the key factors that affect the quality of the molten glass?

- Batch Composition: The ratio of raw materials in the batch determines the final glass properties.

- Furnace Temperature: Proper temperature control is essential to achieve the desired glass melt and avoid defects.

- Melting Time: Sufficient melting time allows impurities to be removed and ensures thorough mixing.

- Fining: Effective fining agents remove bubbles and improve glass clarity.

- Annealing: Proper annealing prevents residual stress, ensuring glass stability.

3. Describe the different types of glass furnaces and their applications?

- Pot Furnaces: Small-scale furnaces used for producing specialty glass and art glass.

- Tank Furnaces: Large furnaces that continuously produce molten glass for mass production.

- Electric Furnaces: Use electricity as the heat source, allowing for precise temperature control.

- Regenerative Furnaces: Recover heat from the exhaust gases to increase energy efficiency.

- Recuperative Furnaces: Preheat the incoming air using heat from the exhaust gases.

4. How do you monitor and control the furnace atmosphere to ensure optimal glass melting conditions?

- Combustion Analysis: Analyze the exhaust gases to maintain a reducing or oxidizing atmosphere as needed.

- Temperature Monitoring: Monitor the temperature at various points in the furnace to ensure uniform heating.

- Glass Sampling: Take samples of the molten glass to check its quality and adjust the furnace atmosphere accordingly.

- Oxygen Control: Regulate the amount of oxygen in the furnace to prevent oxidation or reduction defects.

5. What are the common defects that can occur in molten glass and how do you prevent them?

- Bubbles: Caused by entrapped air or gases; prevented by proper fining and outgassing.

- Stones: Undissolved particles or contaminants; prevented by careful batch preparation and furnace cleaning.

- Cord: Thin streaks in the glass; prevented by thorough mixing and homogenization.

- Striae: Differences in refractive index; prevented by uniform composition and temperature distribution.

6. How do you troubleshoot common furnace problems?

- Furnace Temperature Fluctuations: Check temperature sensors, fuel supply, or air intake.

- Gas Leaks: Conduct inspections, test for leaks, and repair as needed.

- Glass Quality Issues: Analyze glass samples, check furnace atmosphere, and adjust batch composition or furnace conditions.

- Equipment Malfunctions: Inspect equipment, troubleshoot problems, and perform repairs or replacements.

7. Describe your experience with different types of glass production equipment?

I have experience operating and maintaining various glass production equipment, including:

- Glass Batch Mixers: Ensure accurate weighing and mixing of raw materials.

- Furnace Control Systems: Monitor and adjust furnace temperature, atmosphere, and fuel flow.

- Annealing Lehrs: Control the cooling process of molten glass to remove stress and improve its properties.

- Glass Forming Machines: Operate machinery that shapes molten glass into desired products.

8. How do you ensure safety and maintain a clean work environment in a glass furnace operation?

- PPE: Wear appropriate personal protective equipment (e.g., gloves, safety glasses, heat-resistant clothing).

- Hazard Identification: Identify and assess potential hazards associated with glass production.

- Work Area Maintenance: Keep work areas clean and free of tripping or slipping hazards.

- Emergency Procedures: Be familiar with emergency procedures and evacuation routes.

- Housekeeping: Regularly clean and inspect equipment, spills, and waste materials.

9. What are the key performance indicators (KPIs) used to measure the efficiency and effectiveness of a glass furnace tender?

- Furnace Productivity: Tonnes of molten glass produced per hour.

- Glass Quality: Number of defects per tonne of glass produced.

- Energy Efficiency: Amount of fuel consumed per tonne of glass produced.

- Equipment Uptime: Percentage of time furnace equipment is operational.

- Safety Compliance: Number of safety incidents or violations.

10. How do you stay updated with the latest advancements in glass furnace technology?

- Industry Conferences and Trade Shows: Attend events to learn about new technologies and best practices.

- Technical Journals and Publications: Subscribe to industry publications and read technical articles.

- Online Resources: Utilize online forums, webinars, and websites to gather information.

- Collaboration with Vendors: Engage with equipment and technology vendors to stay informed of their latest offerings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Furnace Tenders hold a crucial role in the glass manufacturing industry, with responsibilities encompassing:

1. Furnace Operation and Monitoring

Tenders operate and monitor glass furnaces to ensure optimal production. They adjust temperature, gas flow, and other parameters to produce glass of the desired quality and quantity.

- Maintain stable furnace temperatures and pressure

- Monitor glass levels and adjust accordingly

2. Equipment Maintenance

Tenders perform routine maintenance tasks on furnaces, ensuring their smooth operation and preventing breakdowns. They inspect, clean, and repair equipment as needed.

- Inspect and clean burners, nozzles, and other furnace components

- Replace worn or damaged parts

3. Quality Control

Tenders play a role in quality control by monitoring the glass produced and making adjustments as necessary. They conduct tests to ensure the glass meets specifications and prevent defects.

- Take samples of molten glass for testing

- Adjust process parameters based on test results

4. Safety and Environmental Compliance

Glass Furnace Tenders prioritize safety and adhere to environmental regulations. They wear protective gear, follow safety procedures, and minimize emissions and waste.

- Operate furnaces safely and in accordance with industry standards

- Monitor environmental emissions and take corrective actions if needed

Interview Tips

To excel in a Glass Furnace Tender interview, candidates should:

1. Showcase Technical Knowledge

Emphasize your understanding of glass furnace operation, maintenance, and quality control. Provide specific examples of your technical skills and experience.

- Describe your experience in operating and monitoring furnaces

- Highlight your ability to troubleshoot and resolve furnace issues

2. Demonstrate Safety Awareness

Stress your commitment to safety and your knowledge of industry regulations. Explain how you ensure the safe operation of furnaces and protect yourself and others.

- Discuss your experience with safety protocols and procedures

- Emphasize your understanding of the potential hazards associated with glass furnaces

3. Highlight Problem-Solving Skills

Showcase your ability to identify and solve problems efficiently. Provide examples of how you have handled furnace malfunctions or quality issues in the past.

- Describe a situation where you identified and resolved a furnace problem

- Explain how you analyzed the issue, determined the cause, and implemented a solution

4. Emphasize Communication and Teamwork

Glass Furnace Tenders often work in teams and need to communicate effectively. Highlight your ability to work collaboratively, follow instructions, and share information with others.

- Discuss your experience working in a team environment

- Provide examples of how you have communicated effectively with colleagues and supervisors

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glass Furnace Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!