Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Glue Cook position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

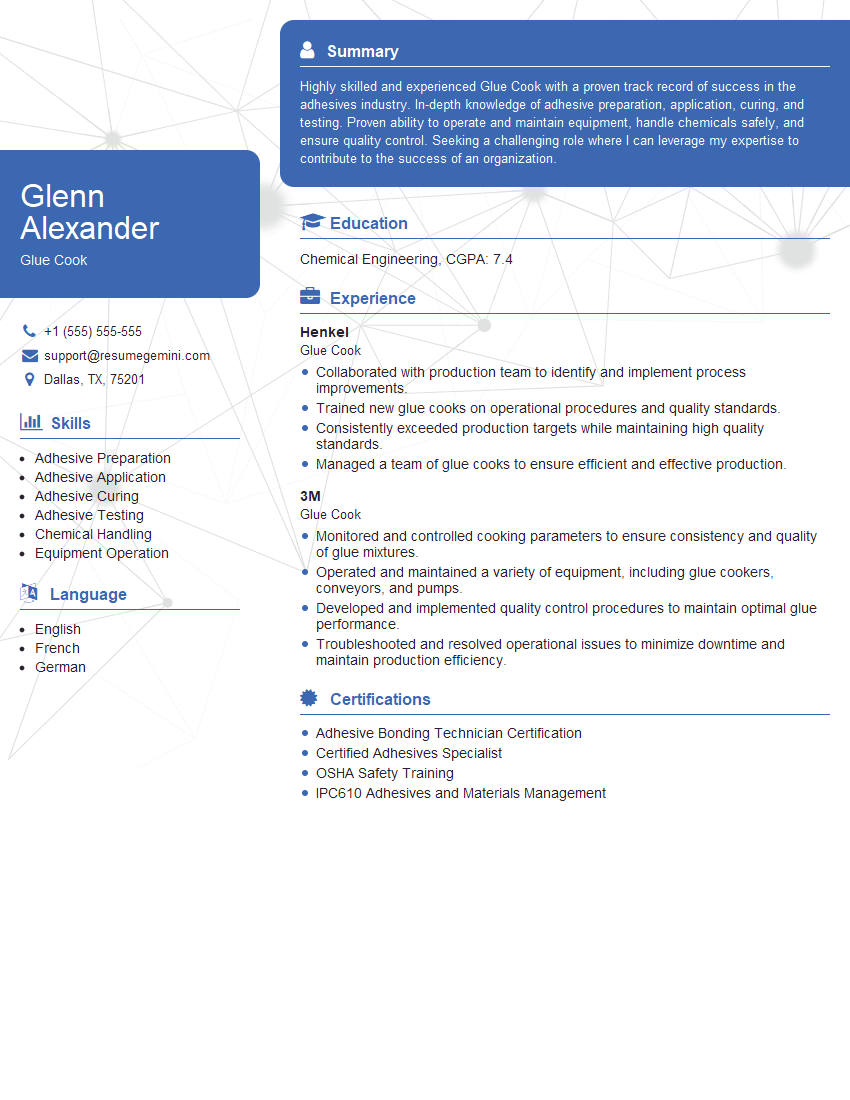

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glue Cook

1. Explain the process of preparing glue from animal skin?

The process of preparing glue from animal skin involves the following steps:

- Soaking the skin: The skin is first soaked in water to remove any dirt or debris. This process can take several hours or even days.

- Liming the skin: The skin is then treated with lime, which helps to remove the hair and fat. This process can take several weeks.

- Fleshing the skin: The skin is then fleshed, which involves removing any remaining flesh or tissue. This process is usually done by hand.

- Washing the skin: The skin is then washed thoroughly to remove any remaining lime or flesh. This process can take several hours.

- Drying the skin: The skin is then dried, either in the sun or in a drying oven. This process can take several days or even weeks.

- Grinding the skin: The dried skin is then ground into a powder. This process can be done by hand or by machine.

- Mixing the powder with water: The powder is then mixed with water to form a glue solution. This process can be done by hand or by machine.

- Heating the solution: The glue solution is then heated until it reaches a boiling point. This process helps to activate the glue.

- Cooling the solution: The glue solution is then cooled until it reaches a room temperature. This process helps to solidify the glue.

- The glue is now ready to use.

2. What are the different types of glue used in woodworking?

Animal glue

- Made from animal skin and bones

- Strong and durable

- Reversible with heat

Hide glue

- Made from cattle hides

- Strong and flexible

- Resistant to moisture

Bone glue

- Made from animal bones

- Strong and brittle

- Not as moisture-resistant as hide glue

Synthetic glue

- Made from synthetic materials

- Strong and durable

- Waterproof

3. What are the advantages and disadvantages of using animal glue in woodworking?

Advantages

- Strong and durable

- Reversible with heat

- Easy to apply

- Affordable

Disadvantages

- Not as strong as synthetic glue

- Not as moisture-resistant as synthetic glue

- Can be difficult to remove

4. What are the safety precautions that should be taken when working with glue?

- Wear gloves and eye protection.

- Avoid contact with skin and eyes.

- Do not ingest glue.

- Use glue in a well-ventilated area.

- Keep glue away from children and pets.

5. What are the different applications of glue in woodworking?

- Joining wood pieces together

- Repairing broken wood pieces

- Laminating wood

- Creating decorative effects

- Adhering other materials to wood, such as metal, plastic, or fabric

6. What are the different factors that affect the strength of a glue joint?

- Type of glue: Different types of glue have different strengths.

- Joint design: The design of the joint affects the strength of the glue bond.

- Surface preparation: The surface of the wood must be clean and free of dirt and debris for the glue to bond properly.

- Clamping pressure: The amount of pressure applied to the joint when it is clamped affects the strength of the glue bond.

- Curing time: The glue must be allowed to cure properly for the bond to reach its full strength.

7. What is the difference between aliphatic resin glue and polyurethane glue?

- Aliphatic resin glue is a water-based glue that is commonly used for woodworking. It is strong and durable, but it is not as moisture-resistant as polyurethane glue.

- Polyurethane glue is a solvent-based glue that is commonly used for bonding metal, plastic, and wood. It is strong, durable, and moisture-resistant.

8. What is the difference between hot glue and cold glue?

- Hot glue is a type of glue that is applied to the surface of the material to be bonded and then heated. This causes the glue to melt and form a bond between the two surfaces.

- Cold glue is a type of glue that is applied to the surface of the material to be bonded and then allowed to dry. This causes the glue to form a bond between the two surfaces.

9. What is the difference between PVA glue and epoxy glue?

- PVA glue is a water-based glue that is commonly used for woodworking and paper crafts. It is strong and durable, but it is not as moisture-resistant as epoxy glue.

- Epoxy glue is a two-part glue that is commonly used for bonding metal, plastic, and wood. It is strong, durable, and moisture-resistant.

10. What is the difference between contact cement and rubber cement?

- Contact cement is a type of glue that is applied to both surfaces of the materials to be bonded and then allowed to dry. This causes the glue to become tacky and bond the two surfaces together.

- Rubber cement is a type of glue that is applied to one surface of the materials to be bonded and then allowed to dry. This causes the glue to become tacky and bond the two surfaces together.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glue Cook.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glue Cook‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glue Cooks play a crucial role in the manufacturing industry by preparing and maintaining adhesives, glues, and other binding agents used in various production processes.

1. Adhesive and Glue Preparation

Prepare and mix adhesives, glues, and other binding agents according to specified formulas.

2. Operating Mixing Equipment

Operate and maintain mixing equipment, such as tanks, kettles, and agitators, to ensure proper mixing and consistency of adhesives.

3. Raw Material Handling

Handle and store raw materials, such as chemicals, powders, and solvents, in a safe and organized manner.

4. Equipment Maintenance

Clean and maintain equipment used in glue preparation, including tanks, pipelines, and mixers.

5. Quality Control

Test and ensure the quality of prepared adhesives and glues to meet the required specifications.

Interview Tips

To ace the interview for a Glue Cook position, candidates should prepare and present themselves effectively.

1. Research the Company and Position

Thoroughly research the company’s website, industry, and the specific role to demonstrate your interest and understanding.

2. Highlight Relevant Experience and Skills

Emphasize your experience in adhesive preparation, equipment operation, and quality control. Highlight any specialized knowledge or training in this field.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows interest and engagement. Prepare questions about the company’s adhesive requirements, sustainability practices, or growth opportunities.

5. Dress Appropriately

Dress professionally, in clothes that are clean, pressed, and suitable for a manufacturing environment.

6. Be Punctual and Enthusiastic

Arrive on time for the interview and demonstrate a positive and enthusiastic attitude. This reflects your professionalism and eagerness to secure the role.

7. Follow Up

After the interview, send a follow-up email or thank-you note to express your appreciation and reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glue Cook interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!