Feeling lost in a sea of interview questions? Landed that dream interview for Label Drier but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Label Drier interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

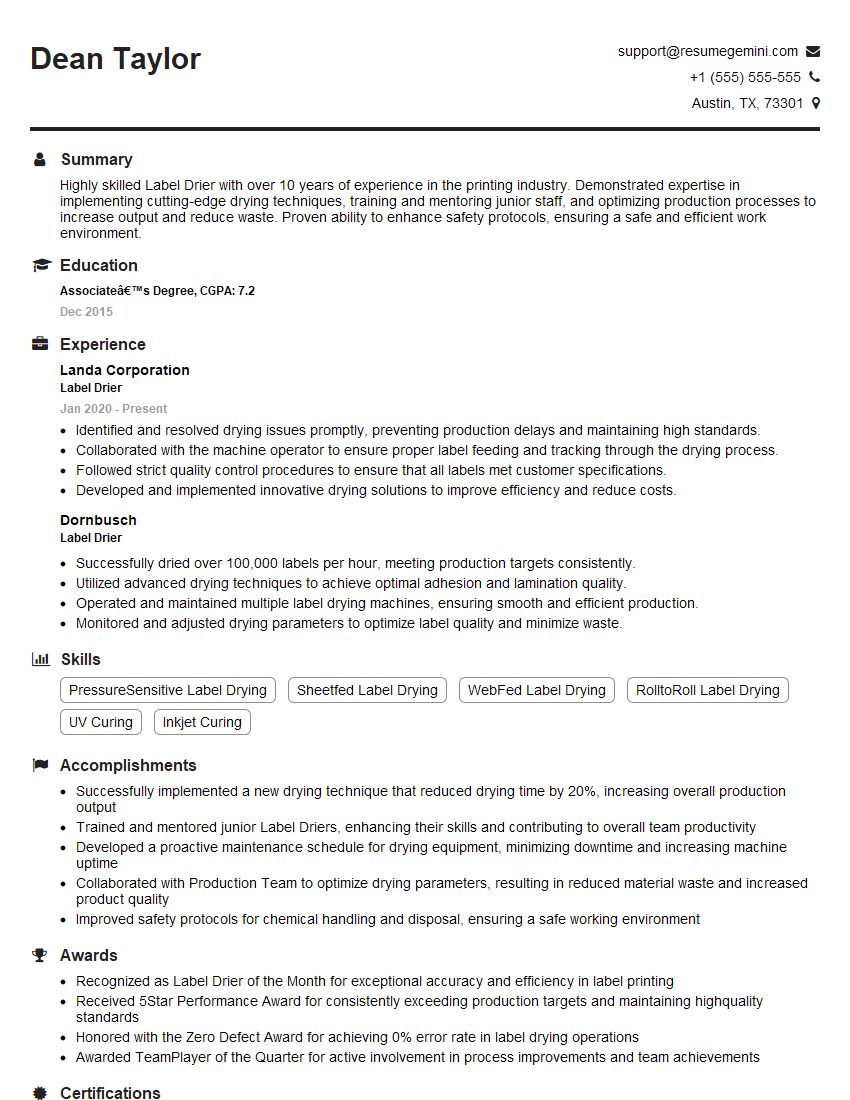

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Label Drier

1. Describe the labeling process on pressure sensitive label driers?

The pressure sensitive label drying process involves several key steps:

- Web Cleaning: The web is cleaned to remove any dust or debris that could interfere with the labeling process.

- Siloxane Primer Coating: A thin layer of siloxane primer is applied to the web to improve the adhesion of the label adhesive.

- Label Application: The pressure-sensitive label is applied to the moving web using a precision applicator.

- Drying and Curing: The labels are subjected to a combination of heat and UV light to dry and cure the adhesive, ensuring a strong bond between the label and the web.

- Quality Control: The finished labels are inspected to ensure accuracy, consistency, and compliance with specifications.

2. What are the common issues encountered during label drying and how do you troubleshoot them?

Label Winkling

- Check for proper tension in the web and label reel.

- Adjust the temperature and curing time to ensure proper adhesive curing.

Label Smudging

- Inspect the UV lamps and replace if necessary.

- Adjust the lamp intensity or exposure time to ensure proper curing.

Label Delamination

- Verify the cleanliness of the web surface and the label adhesive.

- Check the siloxane primer application to ensure proper adhesion.

3. How do you maintain and calibrate a pressure sensitive label drier?

- Regular Cleaning and Inspection: Clean the machine periodically to prevent contamination and ensure smooth operation.

- UV Lamp Calibration: Measure the UV intensity using a UV dosimeter and adjust the lamp settings accordingly.

- Temperature Calibration: Check the temperature sensors and adjust the heating system to maintain optimal temperatures.

- Tension Control: Inspect and adjust the tension rollers to ensure proper web and label tension.

4. What safety precautions should be observed when operating a label drier?

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Ensure proper ventilation to prevent the accumulation of flammable vapors.

- Handle chemicals in accordance with safety data sheets (SDSs).

- Lock out/tag out the machine before performing any maintenance or repairs.

5. How do you optimize the performance of a label drier for maximum efficiency?

- Optimized Tension Control: Adjust the tension rollers to ensure proper web and label tension, minimizing wrinkling and delamination.

- Precise Temperature Control: Maintain optimal temperatures throughout the drying and curing process to ensure proper adhesive bonding.

- UV Lamp Intensity Optimization: Adjust the UV lamp intensity and exposure time to achieve effective curing without over-curing.

- Regular Maintenance: Perform routine cleaning, calibration, and preventive maintenance to prevent downtime and ensure consistent performance.

6. Describe the different types of labels that can be processed on a pressure sensitive label drier and their unique characteristics?

- Paper Labels: Absorbent and economical, suitable for various applications.

- Film Labels: Durable and moisture-resistant, ideal for high-performance applications.

- Foil Labels: Metallic and aesthetically appealing, used for premium branding and tamper-evidence.

- Shrink Sleeves: Conform to the shape of the container, providing tamper-evidence and 360-degree branding.

- RFID Labels: Integrated with RFID chips for tracking and inventory management.

7. How do you handle different label materials with varying thicknesses and adhesives?

Adjusting the machine settings, including tension, temperature, and curing time, is crucial when handling different label materials. For thicker labels, higher tension and longer curing times may be necessary. Different adhesives require specific temperature profiles to ensure proper bonding. By understanding the characteristics of each material, the drier can be optimized for optimal performance.

8. Discuss the environmental and safety considerations related to label drying operations?

- Waste Management: Proper disposal of spent chemicals and adhesive waste.

- Odor Control: Ensuring ventilation to minimize the release of solvent vapors.

- UV Safety: Shielding of UV lamps and wearing appropriate PPE.

- Noise Reduction: Employing sound-dampening measures to reduce noise levels.

9. What is the role of quality control in label drying and how do you ensure consistent label quality?

- Inspection and Verification: Visually inspecting labels for defects and measuring key parameters like adhesion strength and opacity.

- Statistical Process Control (SPC): Monitoring and analyzing data to identify and control process variations.

- Calibration and Maintenance: Maintaining equipment and calibrating sensors to ensure accurate and consistent performance.

- Operator Training: Providing comprehensive training to operators to ensure proper machine operation and quality control procedures.

10. How do you stay updated with the latest advancements and best practices in the label drying industry?

- Industry Publications: Reading trade magazines and journals to stay informed about new technologies and trends.

- Conferences and Exhibitions: Attending industry events to learn about innovations and network with experts.

- Online Resources: Utilizing online platforms to access technical articles, webinars, and research findings.

- Collaboration with Suppliers and Partners: Engaging with vendors and industry partners to gain insights and share knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Label Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Label Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Label Driers are responsible for maintaining and operating dryers that remove moisture from labels, ensuring they are dry and ready for application. The key responsibilities include:

1. Dryer Operation and Maintenance

Operate label dryers to remove moisture from labels efficiently, conserving energy and resources

- Establish correct drying temperatures, tension settings, and speed to ensure proper drying

- Monitor dryer performance, identifying and correcting any malfunctions or irregularities

2. Quality Control and Troubleshooting

Verify the quality of dried labels, ensuring they meet specifications and customer requirements

- Inspect labels for dryness, evenness, and adhesion

- Troubleshoot and resolve issues with dryer performance, achieving optimal efficiency and quality

3. Safety and Compliance

Adhere to established safety protocols, industry standards, and environmental regulations

- Wear appropriate safety gear and follow safety procedures

- Ensure equipment is well-maintained and compliant with regulations

4. Teamwork and Communication

Collaborate with team members and communicate effectively to ensure smooth operations

- Work in coordination with other departments to achieve production goals

- Communicate any issues or improvements to supervisors or colleagues

Interview Tips

Preparing for a Label Drier interview can significantly increase your chances of success. Here are some tips to help you ace it:

1. Research the Company and Position

Thoroughly research the company’s profile, culture, and the specific requirements of the Label Drier position

- Visit the company website and social media pages

- Review job descriptions and industry-related articles

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your skills and experience that are directly relevant to the job

- Quantify your accomplishments using specific metrics

- Provide examples of how you have successfully operated and maintained dryers

3. Showcase Your Problem-Solving Abilities

Label Driers often encounter technical issues. During the interview, highlight your problem-solving skills and how you approach troubleshooting

- Describe a situation where you identified and resolved a dryer malfunction

- Explain your logical thought process and the steps you took to find a solution

4. Practice Common Interview Questions

Familiarize yourself with common interview questions and prepare thoughtful responses

- Why are you interested in this position?

- How do you ensure the quality of dried labels?

5. Ask Informed Questions

Asking well-informed questions at the end of the interview demonstrates your interest and engagement

- Inquire about the company’s growth plans

- Ask about opportunities for professional development

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Label Drier role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.