Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Regenerator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

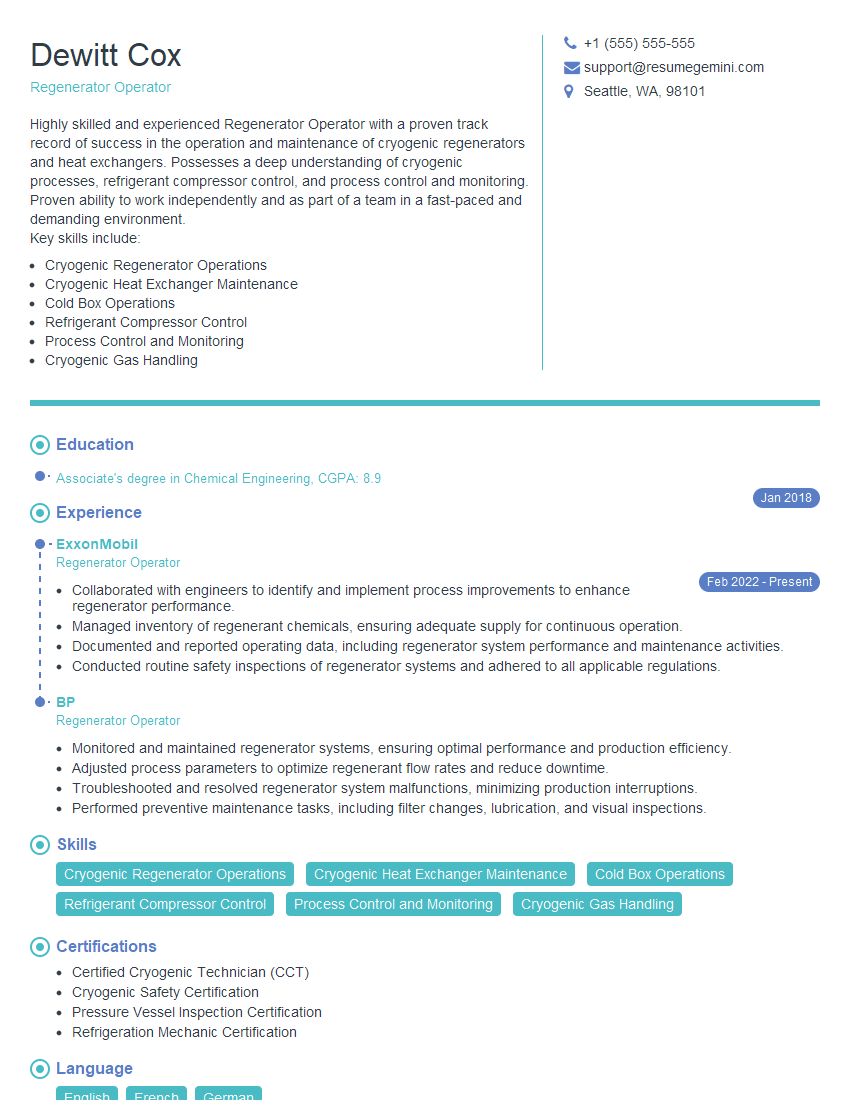

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Regenerator Operator

1. Describe the process of regenerating the catalyst in a Regenerator Operator?

The process of regenerating the catalyst in a Regenerator Operator involves several steps. First, the spent catalyst is removed from the reactor and transferred to the regenerator. The regenerator is a furnace that heats the catalyst to a high temperature, typically between 1,000 and 1,200 degrees Celsius. This high temperature causes the contaminants on the catalyst to be burned off, leaving the catalyst fresh and ready to be reused.

- The catalyst is removed from the reactor and transferred to the regenerator

- The regenerator is a furnace that heats the catalyst to a high temperature

- This high temperature causes the contaminants on the catalyst to be burned off, leaving the catalyst fresh and ready to be reused

2. What are the key parameters that need to be monitored and controlled during the regeneration process?

Temperature

- The temperature of the regenerator is critical, as it must be high enough to burn off the contaminants but not so high that the catalyst is damaged

- The temperature is typically monitored using thermocouples

Pressure

- The pressure in the regenerator must be controlled to prevent the catalyst from being fluidized and carried out of the regenerator

- The pressure is typically monitored using a pressure gauge

Flow rate

- The flow rate of the gas through the regenerator must be controlled to ensure that the catalyst is heated evenly

- The flow rate is typically monitored using a flow meter

3. What are the potential hazards associated with the regeneration process?

The regeneration process can be hazardous if not properly managed. Potential hazards include:

- Fire: The high temperatures involved in the regeneration process can create a fire hazard

- Explosion: The presence of flammable gases and vapors can create an explosion hazard

- Chemical burns: The chemicals used in the regeneration process can cause chemical burns

- Inhalation hazards: The gases and vapors released during the regeneration process can be harmful if inhaled

4. What are the safety precautions that must be taken during the regeneration process?

To ensure the safety of personnel and equipment, it is important to adhere to the following safety precautions during the regeneration process:

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, and goggles

- Follow all written procedures and instructions

- Be aware of the potential hazards associated with the regeneration process

- Inspect the equipment before each use and make sure it is in good working order

- Operate the equipment in a well-ventilated area

- Do not leave the equipment unattended

- In the event of an emergency, immediately shut down the equipment and evacuate the area

5. What are the environmental considerations that must be taken into account during the regeneration process?

The regeneration process can have a negative impact on the environment if not properly managed. Environmental considerations that must be taken into account include:

- Air pollution: The gases and vapors released during the regeneration process can contribute to air pollution

- Water pollution: The wastewater generated during the regeneration process can contain hazardous chemicals

- Solid waste: The spent catalyst that is removed from the reactor is a hazardous waste

6. How can the regeneration process be optimized to improve efficiency and reduce environmental impact?

There are several ways to optimize the regeneration process to improve efficiency and reduce environmental impact:

- Use a more efficient catalyst

- Operate the regenerator at a lower temperature

- Use a more efficient burner

- Recycle the spent catalyst

- Treat the wastewater generated during the regeneration process

7. What are the challenges associated with operating a Regenerator Operator?

Operating a Regenerator Operator can be challenging for several reasons:

- The process is complex and requires a high level of technical expertise

- The process is hazardous and requires strict adherence to safety procedures

- The process is environmentally sensitive and requires careful management to minimize environmental impact

8. What are the rewards of operating a Regenerator Operator?

Operating a Regenerator Operator can be rewarding in several ways:

- The job is challenging and requires a high level of skill and expertise

- The job is essential to the operation of a chemical plant

- The job can provide a good income and benefits

9. What are your qualifications for this position?

I have a Bachelor of Science degree in Chemical Engineering from the University of California, Berkeley. I have also worked as a Regenerator Operator for the past 5 years at a chemical plant in Texas. In this role, I have been responsible for the safe and efficient operation of the regenerator. I am also familiar with the environmental regulations that apply to the regeneration process.

10. Why are you interested in working for our company?

I am interested in working for your company because I am impressed by your commitment to safety and environmental protection. I am also confident that my skills and experience would be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Regenerator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Regenerator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Regenerator Operator is responsible for the efficient and safe operation of a regenerator, which is a machine used to rejuvenate and reuse adsorbents in various industrial processes. The following are their key responsibilities:

1. Operation of Regenerator

The primary responsibility of a Regenerator Operator is to operate the regenerator effectively. This involves:

- Monitoring and controlling all aspects of the regeneration process, including temperature, pressure, and flow rates.

- Ensuring that the regenerator is operating within specified parameters to optimize adsorbent performance and process efficiency.

- Troubleshooting and resolving any operational issues that may arise during the regeneration process.

2. Maintenance and Inspection

Regular maintenance and inspection are crucial to ensure the smooth operation of the regenerator. The operator is responsible for:

- Conducting routine inspections and preventive maintenance tasks to identify and address potential issues.

- Performing repairs and replacements of components as needed to maintain optimal performance.

- Maintaining accurate records of maintenance activities and any issues encountered.

3. Adsorbent Management

The operator is responsible for managing the adsorbents used in the regeneration process:

- Loading and unloading adsorbents from the regenerator.

- Monitoring the condition of the adsorbents and determining when they need to be replaced.

- Ensuring that the adsorbents are stored and handled properly to maintain their effectiveness.

4. Process Optimization

The operator actively participates in improving the regeneration process and optimizing its efficiency:

- Collaborating with engineers and supervisors to identify areas for improvement.

- Testing and implementing new procedures or technologies to enhance the regeneration process.

- Evaluating process data and making recommendations for process optimization.

Interview Tips

Preparing thoroughly for an interview is crucial to making a positive impression. Here are some tips to help you ace your Regenerator Operator interview:

1. Research the Company and Position

Before the interview, take the time to learn about the company, its products or services, and its industry. This demonstrates your interest and enthusiasm for the position and shows that you have taken the initiative to prepare.

- Visit the company’s website, read industry news, and check social media platforms to gather information.

- Review the job description thoroughly to understand the specific requirements and responsibilities of the role.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview. Quantify your accomplishments whenever possible to demonstrate your impact and value.

- Focus on your experience in operating regenerators, including any specific processes or technologies you have worked with.

- Discuss your maintenance and troubleshooting skills, providing examples of how you resolved issues and ensured smooth operation.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to the regeneration process and the equipment used. This may include questions about:

- Regeneration principles and process parameters.

- Adsorbent properties and handling.

- Troubleshooting common operational issues.

4. Demonstrate Your Problem-Solving Abilities

Interviewers often ask hypothetical questions to assess your problem-solving skills. Provide clear and logical answers, explaining your thought process and the steps you would take to resolve the issue.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Provide specific examples from your previous experience that demonstrate your ability to solve problems and make decisions.

5. Practice Common Interview Questions

Prepare answers to common interview questions such as “Tell me about yourself” and “Why are you interested in this position?” Practice delivering your answers clearly and concisely.

- Tailor your answers to the specific job and company.

- Use keywords from the job description to highlight your qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Regenerator Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.