Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Reel Blade Bender Furnace Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Reel Blade Bender Furnace Tender so you can tailor your answers to impress potential employers.

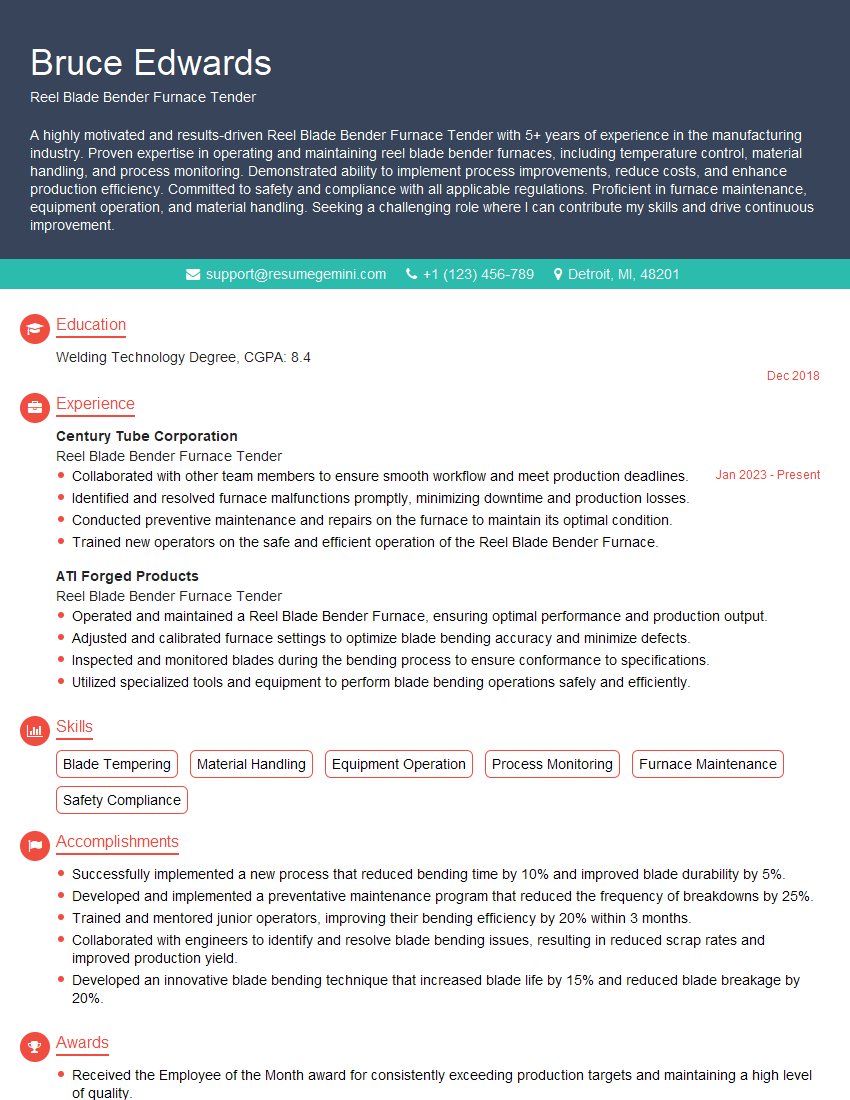

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reel Blade Bender Furnace Tender

1. Describe the key responsibilities of a Reel Blade Bender Furnace Tender?

As a Reel Blade Bender Furnace Tender, my key responsibilities include:

- Operating and maintaining reel blade bender furnaces to bend and shape reel blades according to specifications.

- Monitoring furnace temperatures and adjusting settings to ensure optimal conditions for bending.

- Loading and unloading reel blades into and out of the furnace using specialized equipment.

- Conducting quality checks on finished reel blades to verify dimensional accuracy and surface finish.

- Maintaining a clean and organized work area, ensuring safety protocols and equipment maintenance.

2. Explain the different types of reel blade bender furnaces and their applications?

Electric Resistance Furnace

- Uses electrical resistance to generate heat.

- Precise temperature control and uniform heating.

- Suitable for smaller blades and intricate bending operations.

Gas-Fired Furnace

- Utilizes natural gas or propane to produce heat.

- Higher temperatures than electric furnaces.

- Suitable for large-scale production and bending heavy-duty blades.

Induction Furnace

- Uses electromagnetic induction to heat the blades.

- Rapid heating and precise temperature control.

- Suitable for bending special materials and complex blade geometries.

3. Describe the safety precautions that must be taken when operating a Reel Blade Bender Furnace?

To ensure safety when operating a Reel Blade Bender Furnace, I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE) such as heat-resistant gloves, safety glasses, and protective clothing.

- Inspecting the furnace and equipment before each use, checking for any potential hazards or malfunctions.

- Handling reel blades with care, using proper lifting techniques and avoiding contact with hot surfaces.

- Following established procedures for loading and unloading blades to prevent accidents.

- Maintaining a clean and organized work area, free from tripping hazards and flammable materials.

- Being aware of potential fire risks and knowing the location of fire extinguishers and emergency exits.

- Receiving proper training and authorization before operating the furnace.

4. How do you ensure the quality of the finished reel blades?

To ensure the quality of the finished reel blades, I meticulously follow these steps:

- Verifying blade dimensions and geometry against specifications using precision measuring tools.

- Checking for surface defects, cracks, or other imperfections that may affect blade performance.

- Inspecting the blades for proper heat treatment and material properties.

- Documenting all quality checks and maintaining records of the bending process.

- Working closely with supervisors and quality control personnel to address any quality issues promptly.

- Continuously improving processes and techniques to enhance the overall quality of the blades.

5. Describe the maintenance procedures you perform on Reel Blade Bender Furnaces?

To maintain optimal performance and safety of the furnaces, I regularly perform the following maintenance procedures:

- Cleaning and inspecting all components, including heating elements, burners, and control systems.

- Lubricating and adjusting moving parts to ensure smooth operation.

- Calibrating temperature sensors and controllers for accurate temperature measurement and control.

- Replacing worn or damaged parts as needed to maintain safety and efficiency.

- Documenting maintenance activities and keeping detailed records for future reference.

- Following manufacturer’s instructions and safety guidelines during all maintenance tasks.

6. What troubleshooting techniques do you use when you encounter problems with the Reel Blade Bender Furnace?

When troubleshooting issues with the Reel Blade Bender Furnace, I systematically follow these steps:

- Identifying the problem clearly and gathering information about its symptoms and potential causes.

- Inspecting the furnace and its components visually for any obvious defects or damage.

- Checking electrical connections, temperature sensors, and control systems for proper functionality.

- Reviewing maintenance records and operating logs to identify any previous issues or trends.

- Consulting with supervisors, technical specialists, or manufacturers for guidance and support.

- Implementing corrective actions, such as replacing components, adjusting settings, or performing repairs.

- Testing the furnace after repairs to ensure the problem has been resolved.

7. How do you prioritize your workload and manage multiple tasks efficiently?

To effectively prioritize my workload and manage multiple tasks, I employ the following strategies:

- Creating daily and weekly schedules to plan my tasks and allocate time accordingly.

- Identifying the most critical tasks and prioritizing them based on urgency and importance.

- Breaking down large or complex tasks into smaller, manageable steps.

- Delegating tasks to colleagues or team members when appropriate.

- Utilizing tools and techniques such as checklists, task management software, and kanban boards.

- Communicating regularly with supervisors and colleagues to stay informed and adjust priorities as needed.

- Continuously evaluating my workflow and making adjustments to improve efficiency.

8. How do you contribute to the overall safety and efficiency of the workplace?

I actively contribute to the safety and efficiency of the workplace by:

- Adhering to all safety regulations and procedures, and wearing appropriate personal protective equipment.

- Maintaining a clean, organized, and hazard-free work area.

- Reporting any potential hazards or unsafe conditions to supervisors immediately.

- Participating in safety training and drills to enhance my knowledge and skills.

- Suggesting improvements to processes and procedures to enhance efficiency and productivity.

- Collaborating with colleagues to share best practices and knowledge.

9. How do you stay updated on the latest advancements in Reel Blade Bender Furnace technology?

To stay up-to-date on the latest advancements in Reel Blade Bender Furnace technology, I:

- Attend industry conferences and workshops to learn about new products and techniques.

- Read trade publications and technical journals to stay informed about industry trends.

- Consult with manufacturers and suppliers to get insights into their latest innovations.

- Participate in online forums and discussion groups to connect with other professionals in the field.

- Research and explore emerging technologies that have potential applications in furnace operations.

10. What are your career goals and aspirations?

My career goals and aspirations are to:

- Continue to develop my technical skills and knowledge in Reel Blade Bender Furnace operations.

- Advance to a supervisory role where I can lead and mentor a team of furnace technicians.

- Contribute to the development and improvement of furnace technology through research and innovation.

- Become a recognized expert in the field of Reel Blade Bender Furnace operations.

- Share my knowledge and experience with others to help improve the industry as a whole.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reel Blade Bender Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reel Blade Bender Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Reel Blade Bender Furnace Tender is a vital part of a manufacturing team, operating and maintaining specialized equipment to produce high-quality components for various industries.

1. Furnace Operation and Maintenance

The primary responsibility is to operate and maintain the reel blade bender furnace, ensuring it functions optimally throughout the production process. This includes monitoring temperatures, adjusting settings, and performing preventative maintenance.

- Operate the reel blade bender furnace according to established procedures

- Monitor furnace temperature, pressure, and other operating parameters

- Inspect and maintain furnace equipment, including burners, coils, and safety systems

2. Blade Bending and Inspection

The tender is responsible for bending metal blades to precise specifications. They must inspect incoming materials, set up bending equipment, and ensure the final product meets quality standards.

- Bend metal blades to specified dimensions using the reel blade bender

- Inspect blades for defects, such as cracks, warps, or imperfections

- Adjust bending parameters to achieve the desired shape and angle

3. Material Handling and Inventory Control

The tender assists in handling materials and maintaining inventory levels to support production. They may load and unload materials, assist with storage, and ensure proper inventory records are kept.

- Load and unload materials from the furnace

- Maintain inventory levels of materials

- Keep records of materials usage and production output

4. Health and Safety Compliance

The tender must adhere to strict health and safety protocols to ensure the well-being of themselves and others in the workplace. They must follow proper safety procedures, use personal protective equipment, and maintain a clean and organized work area.

- Follow established safety procedures

- Wear appropriate personal protective equipment

- Maintain a clean and organized work area

Interview Tips

Preparing well for an interview is crucial for a successful outcome. Below are strategic tips to help candidates ace their interview for the Reel Blade Bender Furnace Tender position.

1. Research the Company and Role

Show your interest by researching the company and the specific role you are applying for. Familiarize yourself with the company’s products, services, industry, and mission statement. Understanding the company culture and the demands of the position will help you align your answers to the interviewer’s expectations.

- Visit the company’s website, social media pages, and news articles.

- Review the job description thoroughly and identify the key responsibilities.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job requirements. Provide specific examples from your past work experiences where you successfully performed similar tasks. Quantifying your accomplishments using numbers and metrics is particularly impactful.

- Describe your experience operating and maintaining industrial equipment.

- Discuss your ability to bend metal to precise specifications.

- Mention your knowledge of safety protocols and hazardous materials handling.

3. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare a few insightful questions related to the role, the company’s goals, or industry trends. This demonstrates your proactive nature and eagerness to learn more.

- Ask about the company’s plans for innovation or expansion.

- Inquire about the opportunities for professional development and career advancement.

- Seek clarification on any aspects of the role or company culture that you find particularly interesting.

4. Practice Your Answers

Practice your answers to common interview questions to increase your confidence and deliver clear, concise responses. Anticipate questions related to your technical skills, experience, and motivations. Prepare your answers in advance and practice delivering them in a professional and articulate manner.

- Practice the STAR method (Situation, Task, Action, Result) to structure your answers.

- Seek feedback from a friend, family member, or mentor on your answers.

- Record yourself practicing and review your body language and tone of voice.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview. Choose attire that is clean, pressed, and appropriate for a manufacturing environment. Punctuality is also essential. Plan your travel route in advance to ensure you arrive at the interview location on time.

- Wear closed-toe shoes, comfortable pants, and a button-down shirt or blouse.

- Avoid wearing excessive jewelry or strong scents.

- Allow ample time for travel and arrive a few minutes early.

Next Step:

Now that you’re armed with the knowledge of Reel Blade Bender Furnace Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Reel Blade Bender Furnace Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini