Feeling lost in a sea of interview questions? Landed that dream interview for Tray Drier Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tray Drier Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

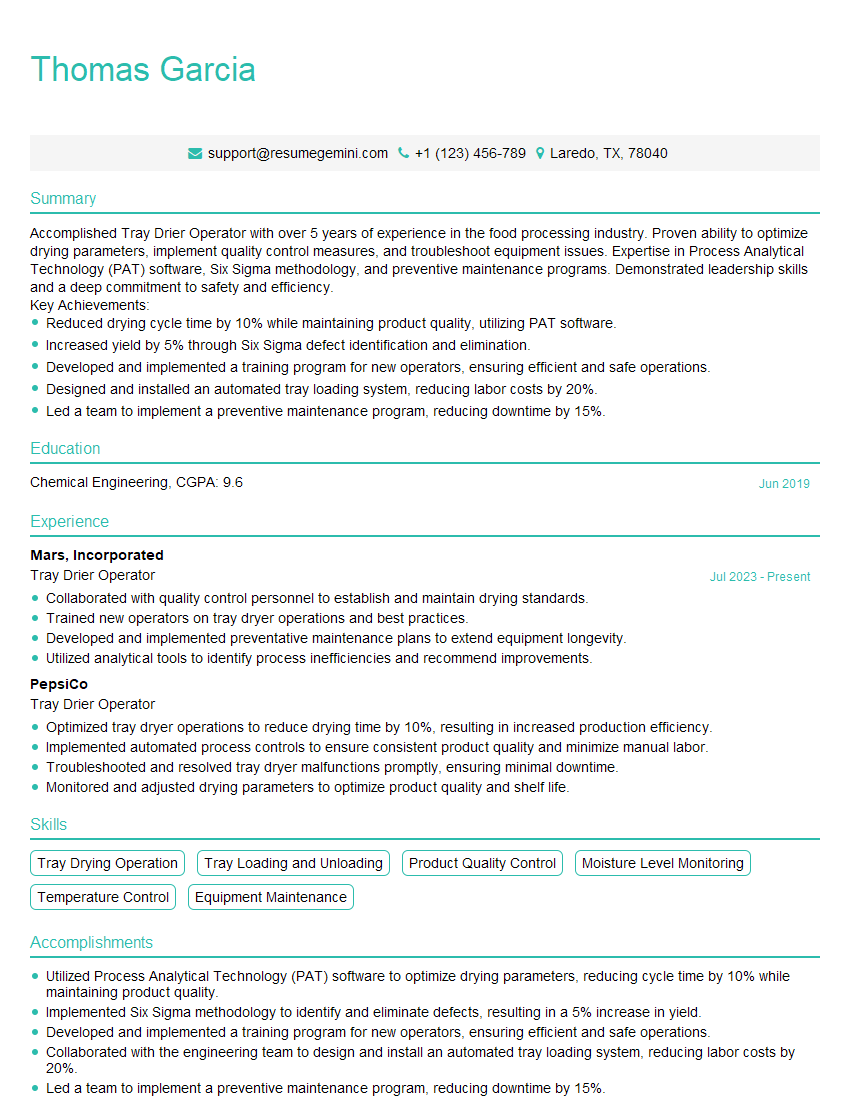

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tray Drier Operator

1. How do you ensure the proper temperature distribution within the tray drier?

To ensure proper temperature distribution within the tray drier, I employ several techniques:

- Proper placement of heating elements: I ensure the heating elements are evenly distributed throughout the drier to provide uniform heat distribution.

- Airflow management: I control the airflow rate and direction to create air circulation patterns that promote even temperature distribution.

- Monitoring and adjustments: I regularly monitor the temperature at various points in the drier using thermocouples or other sensors. Based on the readings, I make necessary adjustments to the heating elements and airflow to achieve the desired temperature profile.

2. Describe the steps involved in troubleshooting excessive moisture content in the dried product.

Identifying the source of moisture:

- Check the raw material for moisture content and ensure it meets specifications.

- Examine the trays for any damage or leaks that may allow moisture to enter the drier.

- Inspect the seals around the drier doors and access points.

Optimizing drying conditions:

- Increase the temperature and/or airflow rate to enhance evaporation.

- Extend the drying time to allow for more moisture removal.

- Adjust the tray spacing or loading density to improve airflow and prevent moisture buildup.

Other considerations:

- Check the humidity levels in the surrounding environment and take corrective measures if necessary.

- Inspect the exhaust system to ensure proper moisture removal.

- Review the maintenance records for the drier and address any overdue maintenance tasks.

3. How do you calibrate and maintain the hygrometer used to measure the humidity in the tray drier?

I follow a comprehensive procedure to calibrate and maintain the hygrometer:

- Calibration:

- Use a saturated salt solution of known humidity.

- Place the hygrometer in the solution and adjust the dial until the reading matches the known humidity level.

- Maintenance:

- Clean the hygrometer sensor regularly using a soft brush or compressed air.

- Protect the sensor from dust, dirt, and liquids.

- Check the hygrometer’s accuracy periodically by comparing its readings to a reference hygrometer.

4. Explain the importance of controlling the airflow rate and direction in the tray drier.

Controlling the airflow rate and direction in the tray drier is crucial for several reasons:

- Uniform drying: Proper airflow ensures even distribution of heat and moisture throughout the drier, resulting in consistent drying.

- Moisture removal: Adequate airflow removes moisture vapor from the drying chamber, preventing condensation and product spoilage.

- Energy efficiency: Optimized airflow minimizes energy waste by directing hot air to the product rather than heating the surrounding air.

- Product quality: Controlled airflow prevents product damage due to excessive heat or moisture exposure.

5. Describe the safety procedures you follow when operating the tray drier.

I adhere to the following safety procedures when operating the tray drier:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a lab coat.

- Ensure the drier is properly grounded and electrical connections are secure.

- Check the drier for any damage or leaks before operation.

- Never reach into the drier while it is operating.

- Handle hot trays with caution to avoid burns.

- Keep the area around the drier clean and free from tripping hazards.

6. Explain how you monitor the drying process to ensure product quality.

To monitor the drying process and ensure product quality, I implement the following measures:

- Regular monitoring: I regularly check the temperature, humidity, and moisture content of the product during the drying cycle.

- Sampling and testing: I take samples of the product at various intervals to assess its moisture content and other quality parameters.

- Data logging: I record the monitoring data and sample results to track the drying progress and make informed decisions.

- Visual inspection: I visually inspect the product for any signs of overdrying, underdrying, or other defects.

7. Describe the maintenance tasks you perform on the tray drier to ensure its optimal performance.

I perform the following maintenance tasks to ensure optimal performance of the tray drier:

- Regular cleaning: I clean the trays, heating elements, and other components of the drier to prevent buildup and maintain hygiene.

- Lubrication: I lubricate moving parts, such as fans and bearings, to minimize friction and wear.

- Inspection and repair: I inspect the drier regularly for any damage or wear and make necessary repairs promptly.

- Calibration: I calibrate the temperature and humidity sensors to ensure accurate readings.

8. How do you troubleshoot common problems that may occur during tray drier operation?

To troubleshoot common problems during tray drier operation, I follow these steps:

- Identify the problem: I observe the symptoms and determine the potential causes.

- Check the equipment: I inspect the drier, its components, and the power supply for any visible issues or damage.

- Review the operating parameters: I check if the temperature, humidity, and airflow settings are appropriate.

- Consult documentation: I refer to the drier’s manual or technical specifications for guidance.

- Implement solutions: Based on my findings, I make adjustments to the settings, perform maintenance tasks, or contact a technician.

9. What are the key factors to consider when selecting a tray drier for a specific application?

When selecting a tray drier for a specific application, I consider the following key factors:

- Product characteristics: The type of product, its moisture content, and desired final moisture level.

- Drying capacity: The required drying rate and the amount of product to be processed.

- Energy efficiency: The operating costs and environmental impact associated with different drying methods.

- Space constraints: The available space for the drier and its ancillary equipment.

- Cost: The capital and operating costs of different types of tray driers.

10. How do you stay updated with the latest advancements in tray drier technology?

To stay updated with the latest advancements in tray drier technology, I engage in the following activities:

- Attend industry conferences and workshops: These events provide opportunities to learn about new technologies and trends.

- Read technical journals and articles: I subscribe to industry publications and access online resources to stay informed about research and developments.

- Connect with industry professionals: I participate in online forums and discussion groups to exchange knowledge and insights.

- Visit manufacturers’ websites: I explore the websites of leading tray drier manufacturers to learn about their latest products and innovations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tray Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tray Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tray Drier Operators are responsible for operating and maintaining tray driers, which are used to remove moisture from various materials. Their primary duties include:

1. Equipment Operation

Operate and monitor tray driers, ensuring they function efficiently and safely.

- Set up and adjust drying parameters, such as temperature, humidity, and airflow.

- Monitor dryer performance and make adjustments as needed to optimize drying conditions.

2. Material Handling

Load and unload materials into and out of the dryer.

- Ensure materials are properly spread on trays and meet quality standards.

- Monitor material moisture levels and adjust drying time accordingly.

3. Quality Control

Inspect and test dried materials to ensure they meet specified quality requirements.

- Conduct visual inspections and perform laboratory tests to verify moisture content and other parameters.

- Record and maintain quality control data for traceability and compliance purposes.

4. Maintenance and Troubleshooting

Perform routine maintenance and repairs on tray driers and associated equipment.

- Identify and rectify potential issues to ensure optimal dryer performance.

- Work with maintenance personnel as needed for major repairs or equipment upgrades.

5. Safety and Compliance

Adhere to safety protocols and comply with environmental regulations.

- Wear appropriate personal protective equipment (PPE) and follow all safety guidelines.

- Maintain a clean and organized work area, ensuring compliance with safety and environmental standards.

Interview Tips

To ace an interview for a Tray Drier Operator position, it’s crucial to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and Role

Familiarize yourself with the company’s history, operations, and industry standing.

- Review the job description meticulously to understand the specific responsibilities and qualifications required.

- If possible, visit the company’s website or social media pages to gain insights into their culture and values.

2. Highlight Relevant Experience

Emphasize your previous experience operating and maintaining tray driers or similar equipment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Explain how your skills and knowledge align with the job requirements, highlighting any certifications or training you possess.

3. Demonstrate Safety and Quality Control Awareness

Show the interviewer that you prioritize safety and quality control in your work.

- Discuss your knowledge of safety protocols and regulations related to tray dryer operation.

- Highlight your ability to conduct quality inspections and adhere to quality standards in a systematic manner.

4. Prepare Questions to Ask

Asking thoughtful questions shows that you’re engaged and interested in the position.

- Inquire about the company’s growth plans and how the Tray Drier Operator role fits into their strategy.

- Ask about opportunities for professional development and training within the organization.

5. Practice Your Answers

Rehearse your responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Prepare concise and compelling answers that showcase your qualifications and enthusiasm for the position.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses effectively.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tray Drier Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.