Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Varnish Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

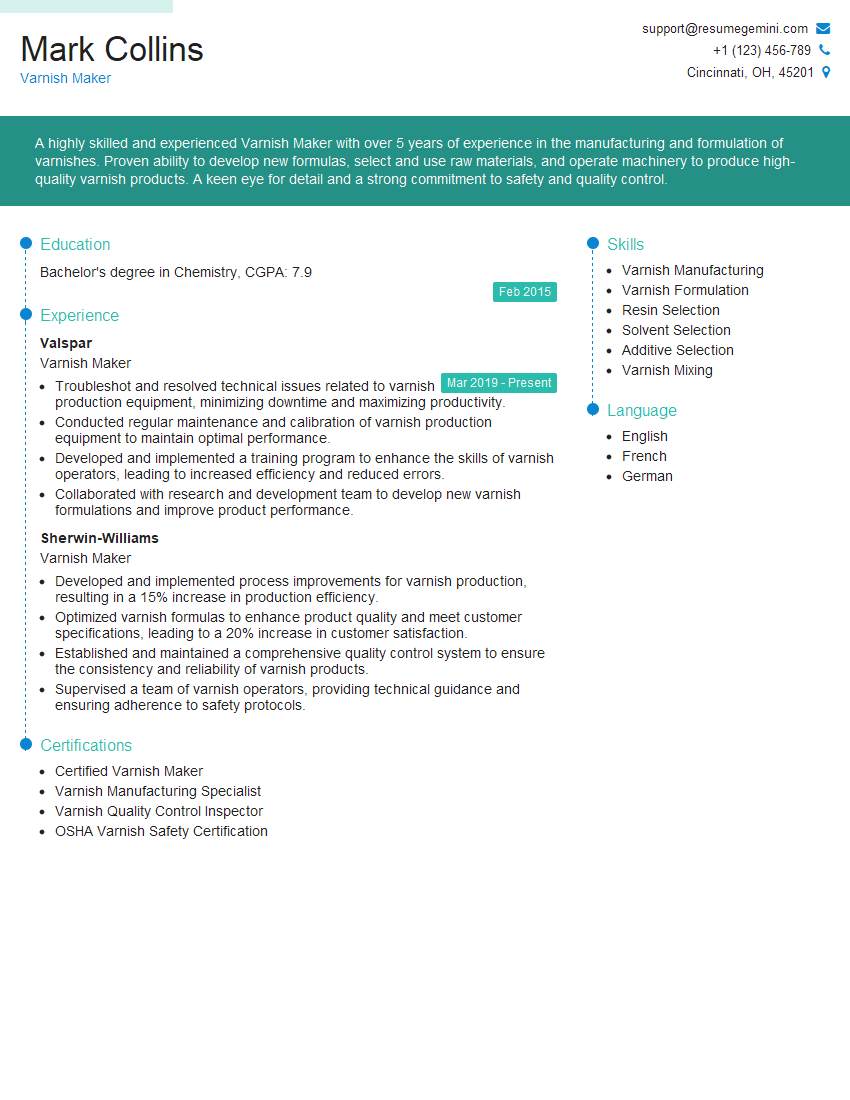

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Varnish Maker

1. What are the key ingredients used in varnish making?

- Resins: Natural or synthetic substances that provide the film-forming properties of varnish.

- Solvents: Liquids that dissolve the resins and allow them to be applied as a thin film.

- Additives: Substances added to enhance specific properties of the varnish, such as durability, gloss, or resistance to chemicals.

2. Describe the process of manufacturing varnish.

Mixing the Ingredients

- Proportions of resins, solvents, and additives are carefully weighed and mixed in a controlled environment.

- Mixing equipment, such as high-speed dispersers, ensures thorough blending.

Heating and Cooking

- The mixture is heated to dissolve the resins and create a homogeneous solution.

- The temperature and cooking time are closely monitored to prevent degradation of the varnish.

Cooling and Filtration

- The hot varnish is cooled to room temperature, causing suspended solids to settle out.

- The varnish is then filtered to remove impurities and ensure a smooth, uniform consistency.

3. What are the different types of varnishes used for wood finishing?

- Oil-Based Varnishes: Traditional varnishes made with resins dissolved in oil solvents, providing excellent durability and water resistance.

- Water-Based Varnishes: Varnishes made with resins dispersed in water, offering non-toxic and easy cleanup characteristics.

- Urethane Varnishes: Varnishes made with urethane resins, known for their fast drying times and high resistance to wear and tear.

- Polyurethane Varnishes: Varnishes made with polyurethane resins, providing exceptional durability, gloss, and scratch resistance.

4. How do you determine the appropriate viscosity of varnish for a given application?

- Consider the surface to be coated and its intended use.

- Thick varnishes provide higher protection but may be difficult to apply smoothly.

- Thin varnishes penetrate better and are easier to apply but offer less durability.

- Viscosity can be adjusted by adding solvents or thinners.

5. What are the most common defects in varnish finishes and how can they be prevented?

- Bubbles: Caused by entrapped air, can be prevented by proper mixing and degassing the varnish.

- Crazing: Fine cracks in the varnish film, caused by poor adhesion or excessive shrinkage, can be reduced by using the correct primer and applying thin coats.

- Hazing: A milky or cloudy appearance, caused by improper drying conditions or contamination, can be avoided by ensuring proper ventilation and cleanliness.

- Yellowing: Discoloration of the varnish over time, can be minimized by using UV-resistant components.

6. How do you maintain and extend the life of varnish finishes?

- Regular cleaning and dusting to remove dirt and debris.

- Periodic touch-ups to repair scratches or wear.

- Avoid excessive exposure to sunlight and moisture.

- Apply a fresh coat of varnish as needed to restore protection and enhance durability.

7. What safety precautions should be taken when handling and applying varnishes?

- Wear protective clothing, gloves, and eye protection.

- Ensure adequate ventilation to prevent inhalation of solvents.

- Store varnishes in a cool, dry, and well-ventilated area.

- Follow manufacturer’s instructions and avoid direct contact with skin and eyes.

8. How do you keep up with the latest advances in varnish technology?

- Attend industry conferences and workshops.

- Read trade publications and research journals.

- Network with other varnish makers and experts.

- Explore online resources and manufacturer websites.

9. What are some innovative applications of varnishes in modern industries?

- Optical Coatings: UV resistant varnishes for lenses, filters, and mirrors.

- Industrial Coatings: Protective and anti-corrosive varnishes for machinery, pipelines, and metal structures.

- Printed Circuit Boards: Varnishes used to insulate and protect electronic circuits.

- Automotive Finishes: Varnishes for enhancing the appearance and durability of vehicle paint.

10. How do you ensure the quality of your varnishes meet industry standards?

- Adherence to standardized manufacturing processes.

- Regular quality control testing, using industry-recognized methods.

- Calibration and maintenance of equipment.

- Strict monitoring of raw material quality and consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Varnish Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Varnish Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Varnish Makers are responsible for producing, maintaining, and testing varnishes and coatings. Their duties involve formulating, mixing, and applying varnishes, ensuring optimal adhesion, color, and resistance to wear and tear. They also conduct tests on raw materials and finished products to verify compliance with specifications. Additionally, they may provide technical guidance to customers and perform maintenance on equipment.

1. Formulate and Mix Varnishes

Develop and improve varnish formulations based on customer requirements and industry standards.

- Determine the appropriate ratios of ingredients, including resins, solvents, and additives.

- Mix and blend ingredients thoroughly using specialized equipment to ensure a uniform and consistent product.

2. Apply Varnishes

Apply varnishes to surfaces using various techniques, such as spraying, brushing, or dipping.

- Prepare surfaces by cleaning and sanding to ensure proper adhesion.

- Control application thickness and uniformity to meet specified requirements.

- Monitor drying time and make adjustments as necessary.

3. Test Raw Materials and Finished Products

Conduct quality control tests on raw materials and finished products to ensure compliance with specifications.

- Use standardized testing methods to evaluate properties such as viscosity, color, and durability.

- Interpret test results and make adjustments to formulations as needed.

4. Provide Technical Guidance

Provide technical guidance to customers on product selection, application techniques, and troubleshooting.

- Analyze customer needs and recommend appropriate varnish products.

- Offer detailed instructions on application methods and safety precautions.

Interview Tips

To prepare for an interview for a Varnish Maker position, candidates should focus on demonstrating their technical knowledge, experience in varnish formulation and application, and ability to work independently and as part of a team.

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company’s website and social media pages.

- Read trade publications and attend industry events.

2. Practice Answering Common Interview Questions

Prepare answers to questions about your experience in varnish making, testing procedures, and technical troubleshooting.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your key skills and accomplishments.

3. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you are engaged and interested in the position.

- Inquire about the company’s specific varnish production processes.

- Ask about opportunities for professional development and growth.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately and arrive for your interview on schedule.

- Wear business attire or clean, pressed clothing.

- Arrive 15-20 minutes early to allow time for check-in.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Varnish Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Varnish Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.