Feeling lost in a sea of interview questions? Landed that dream interview for Bench Assembly Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bench Assembly Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

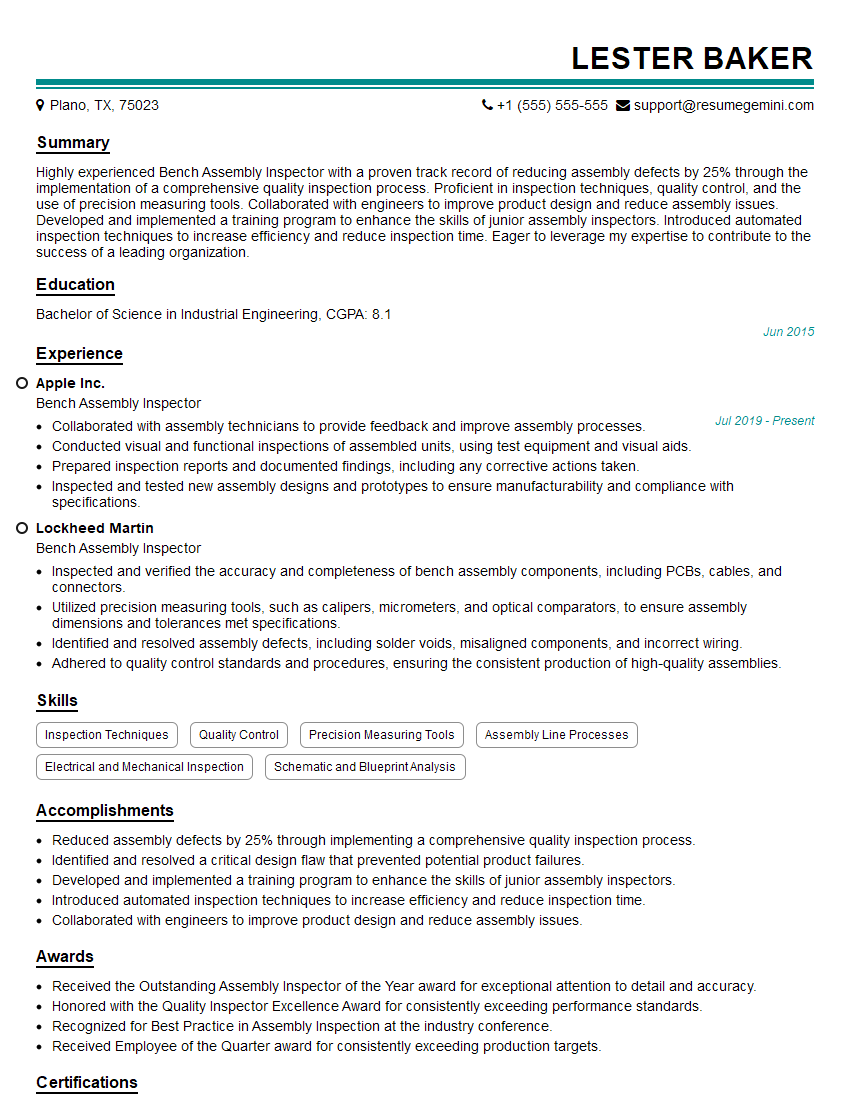

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bench Assembly Inspector

1. Describe the key responsibilities of a Bench Assembly Inspector?

The primary responsibilities of a Bench Assembly Inspector involve:

- Inspecting and assembling components to ensure compliance with specifications

- Verifying dimensions, tolerances, and finishes of assembled products

- Identifying and documenting defects or non-conformities

- Performing quality control checks and maintaining accurate records

- Adhering to safety protocols and maintaining a clean and organized work area

2. Explain the different types of inspection tools and gauges used in bench assembly?

Precision Measuring Tools:

- Micrometers for measuring precise dimensions

- Calipers for measuring length, height, and depth

- Dial indicators for measuring minute variations

Gauges:

- Go/No-go gauges for checking tolerances

- Thread gauges for verifying thread specifications

- Radius gauges for measuring curved surfaces

3. How do you prioritize inspection tasks based on their criticality?

I prioritize inspection tasks based on the following criteria:

- Safety: Inspecting for any potential hazards or defects that could impact safety

- Functionality: Ensuring that critical components and assemblies meet functional requirements

- Compliance: Verifying adherence to industry standards and customer specifications

- Cost: Prioritizing inspections that can prevent costly repairs or rework

- Time: Allocating resources to tasks that require immediate attention to maintain production timelines

4. Describe your approach to documenting inspection results?

I document inspection results meticulously and accurately using the following methods:

- Inspection Logs: Maintaining a detailed record of inspected items, including specifications, measurements, and any identified defects

- Quality Control Reports: Summarizing inspection findings, identifying trends, and recommending corrective actions

- Digital Inspection Software: Utilizing software tools to capture inspection data, generate reports, and track quality metrics

5. How do you handle non-conforming products during inspection?

When non-conforming products are identified, I adhere to the following steps:

- Isolate the Product: Segregating non-conforming products to prevent their release into the production process

- Document the Non-Conformity: Clearly recording the defects or deviations from specifications

- Notify the Supervisor: Informing management or quality control personnel about the non-conformance

- Initiate Corrective Action: Collaborating with production teams to identify the root cause and implement corrective measures

6. What are your strategies for improving inspection efficiency without compromising accuracy?

To enhance inspection efficiency while maintaining accuracy, I employ the following strategies:

- Standardization: Establishing clear inspection protocols and procedures to ensure consistency and minimize errors

- Automation: Utilizing automated inspection equipment or software to streamline repetitive tasks and reduce human error

- Training: Providing comprehensive training to inspectors to improve their skills and knowledge

- Ergonomics: Optimizing the inspection workstation to reduce fatigue and improve productivity

7. How do you stay updated on industry best practices and technological advancements in bench assembly inspection?

To remain current with industry best practices and technological advancements, I engage in the following activities:

- Attend Industry Events: Participating in conferences and exhibitions to connect with experts and learn about new technologies

- Read Trade Publications: Subscribing to industry journals and online resources to stay informed about the latest trends

- Network with Peers: Connecting with other bench assembly inspectors to share knowledge and experiences

- Obtain Certifications: Pursuing industry-recognized certifications to demonstrate my commitment to quality and professional development

8. How do you manage multiple inspection tasks simultaneously while ensuring accuracy?

To manage multiple inspection tasks concurrently while maintaining accuracy, I employ the following strategies:

- Prioritization: Triaging tasks based on urgency and criticality to focus on the most important items first

- Organization: Establishing a structured workflow and using checklists to ensure that all inspection points are covered

- Time Management: Allocating sufficient time for each task and avoiding multitasking to prevent errors

- Cross-Checking: Regularly reviewing my own work and conducting peer reviews to minimize the risk of missed defects

9. Provide an example of a time when you identified a critical defect during an inspection that prevented a major problem.

In a recent inspection, I discovered a hairline crack in a critical component of an assembly. The crack was not immediately visible, but I noticed a slight deviation in the component’s dimension during measurement. This deviation prompted me to conduct further examination using a magnifying glass, which revealed the crack.

By identifying this defect early, we prevented the assembly from being released into production, where it could have caused a catastrophic failure. The defective component was replaced, and the assembly underwent rigorous testing to ensure its integrity before being approved for use.

10. What are your strengths as a Bench Assembly Inspector?

My strengths as a Bench Assembly Inspector include:

- Attention to Detail: I am meticulous and thorough in my inspections, ensuring that all critical dimensions and specifications are met

- Problem-Solving Skills: I am adept at identifying and resolving non-conformities, and I can quickly determine the root cause of defects

- Communication Skills: I am effective at communicating inspection results and documenting findings clearly and concisely

- Teamwork: I work well both independently and as part of a team, collaborating with production personnel to ensure quality standards are met

- Adaptability: I am comfortable adjusting to changing inspection requirements and learning new inspection techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bench Assembly Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bench Assembly Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bench Assembly Inspectors are responsible for ensuring that products meet specifications by inspecting and testing them. They also identify and correct defects, and provide feedback to improve the manufacturing process.

1. Inspecting and testing products

Bench Assembly Inspectors inspect and test products to ensure that they meet specifications. They use a variety of tools and equipment to check for defects, such as visual inspection, micrometers, and calipers.

- Inspect products for defects, such as missing or damaged parts, incorrect assembly, or poor workmanship.

- Test products to ensure that they function properly, such as by checking for electrical continuity, mechanical operation, or fluid leaks.

2. Identifying and correcting defects

Bench Assembly Inspectors identify and correct defects in products. They may use rework or repair techniques to fix defects, or they may scrap products that are beyond repair.

- Identify and document defects in products.

- Determine the cause of defects and recommend corrective actions.

- Repair or rework products to correct defects.

3. Providing feedback

Bench Assembly Inspectors provide feedback to improve the manufacturing process. They may identify areas where the process can be improved, or they may suggest new methods or techniques for assembling products.

- Provide feedback to management on the quality of products and the efficiency of the manufacturing process.

- Suggest improvements to the manufacturing process to reduce defects and improve quality.

- Train new employees on assembly and inspection procedures.

Interview Tips

Preparing for an interview for a Bench Assembly Inspector position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Take some time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a Bench Assembly Inspector.

- Visit the company’s website to learn about their products, services, and mission.

- Read online reviews of the company to get an idea of their culture and work environment.

- Review the job description carefully to understand the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself, including your experience and skills.

- Brainstorm reasons why you’re interested in the position and the company.

- Think about specific examples of your work experience that demonstrate your skills and abilities.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Bench Assembly Inspector. Be prepared to discuss your experience in detail, including the types of products you’ve inspected, the tools and equipment you’ve used, and the quality standards you’ve met.

- Highlight your experience in inspecting and testing products.

- Describe your skills in identifying and correcting defects.

- Emphasize your ability to provide feedback and improve the manufacturing process.

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive at the interview location on time, or even a few minutes early.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Now that you’re armed with the knowledge of Bench Assembly Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bench Assembly Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini