Are you gearing up for a career in Block Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Block Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

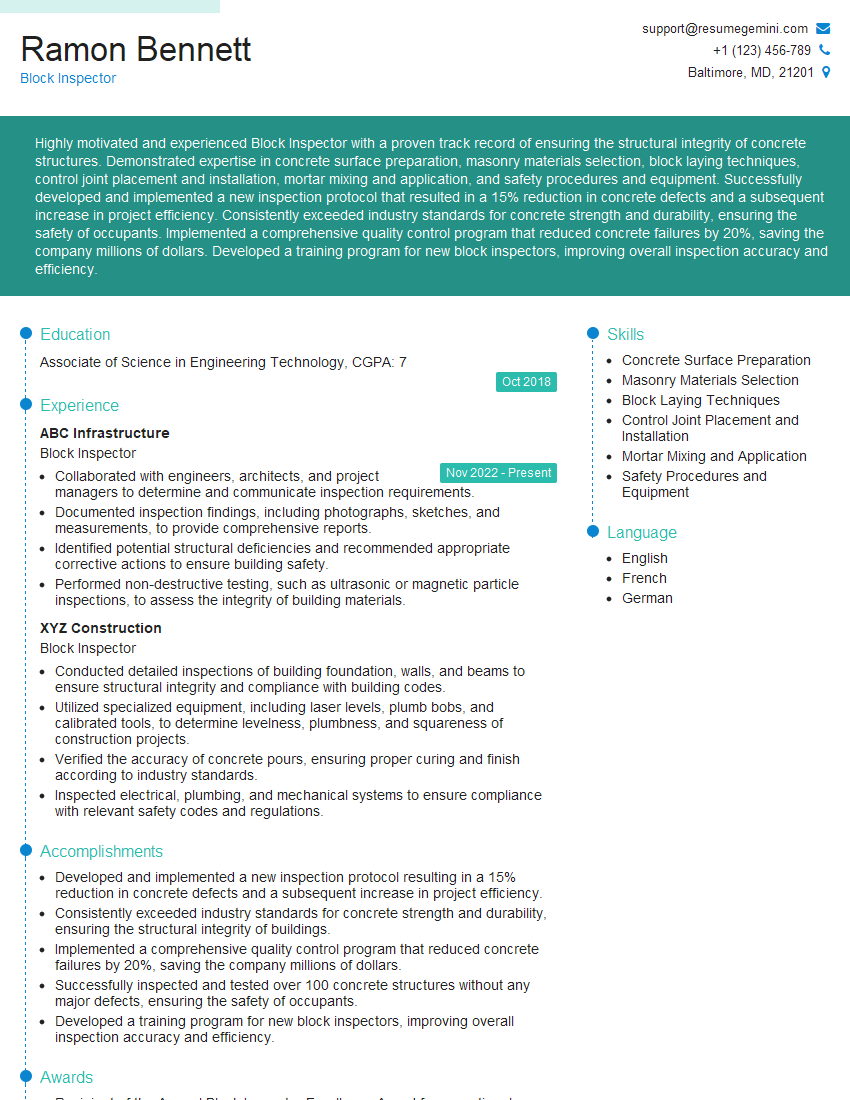

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Inspector

1. What are the key responsibilities of a Block Inspector?

The key responsibilities of a Block Inspector include:

- Inspecting the quality of concrete blocks and ensuring they meet specifications.

- Checking for defects, such as cracks, voids, or uneven surfaces.

- Measuring and recording the dimensions and weight of blocks.

- Maintaining records of inspections and reporting any non-conforming blocks.

- Working with production staff to identify and resolve quality issues.

2. What are the different types of concrete blocks?

There are several types of concrete blocks, including:

- Solid blocks: These blocks are made from a solid piece of concrete and are used for structural applications.

- Hollow blocks: These blocks have voids or holes in them, which makes them lighter and more economical than solid blocks.

- Lightweight blocks: These blocks are made with lightweight aggregates, such as pumice or expanded clay, which makes them ideal for non-load-bearing applications.

- Architectural blocks: These blocks are designed to be aesthetically pleasing and are used for decorative purposes.

3. What are the most common defects found in concrete blocks?

The most common defects found in concrete blocks include:

- Cracks: Cracks can be caused by a variety of factors, such as improper curing or excessive loads.

- Voids: Voids are air pockets that can occur during the manufacturing process.

- Uneven surfaces: Uneven surfaces can be caused by improper molding or handling.

- Spalling: Spalling is the chipping or flaking of the concrete surface.

- Efflorescence: Efflorescence is the formation of white or grayish deposits on the surface of the block, which is caused by the leaching of soluble salts.

4. What are the quality control measures that can be used to prevent defects in concrete blocks?

There are several quality control measures that can be used to prevent defects in concrete blocks, including:

- Using high-quality materials

- Properly mixing and curing the concrete

- Inspecting the blocks at various stages of the manufacturing process

- Testing the blocks to ensure they meet specifications

- Maintaining a clean and organized work area

5. What are the ASTM standards that apply to concrete blocks?

The following ASTM standards apply to concrete blocks:

- ASTM C90: Standard Specification for Loadbearing Concrete Masonry Units

- ASTM C129: Standard Specification for Non-Loadbearing Concrete Masonry Units

- ASTM C140: Standard Test Methods for Sampling and Testing Concrete Masonry Units

- ASTM C150: Standard Specification for Portland Cement

- ASTM C476: Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

6. What are the safety precautions that should be taken when working with concrete blocks?

When working with concrete blocks, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Use proper lifting techniques to avoid injury.

- Be aware of the hazards of working with heavy materials.

- Keep the work area clean and free of debris.

- Follow all safety regulations and procedures.

7. What are the advantages of using concrete blocks for construction?

Concrete blocks offer several advantages for construction, including:

- Strength and durability

- Fire resistance

- Sound insulation

- Thermal insulation

- Cost-effectiveness

- Versatility

8. What are the disadvantages of using concrete blocks for construction?

There are also some disadvantages to using concrete blocks for construction, including:

- Weight

- Size

- Complexity of installation

- Susceptibility to moisture

- Environmental impact

9. What are the trends in the concrete block industry?

The concrete block industry is constantly evolving, with new trends emerging all the time. Some of the most recent trends include:

- The use of sustainable materials

- The development of new block shapes and sizes

- The use of advanced manufacturing techniques

- The integration of technology into the block-making process

- The growth of the global block market

10. What are the challenges facing the concrete block industry?

The concrete block industry also faces a number of challenges, including:

- The rising cost of raw materials

- The increasing competition from other building materials

- The need for more sustainable practices

- The shortage of skilled labor

- The impact of climate change

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Inspectors are responsible for ensuring that concrete blocks meet the required standards for quality and safety. They perform various tasks to ensure that the blocks are free from defects and are suitable for construction purposes.

1. Inspection of Concrete Blocks

Inspecting concrete blocks for conformity to specifications.

- Dimensions

- Strength

- Finish

2. Testing of Concrete Blocks

Conducting tests to determine the physical properties of concrete blocks, such as compressive strength, flexural strength, and water absorption.

- Compressive strength test

- Flexural strength test

- Water absorption test

3. Monitoring of Production Process

Monitoring the production process to ensure that it meets the required standards.

- Raw materials

- Mixing

- Curing

4. Reporting and Documentation

Preparing reports and maintaining records of inspections and tests.

- Inspection reports

- Test reports

- Quality control records

Interview Tips

Preparing for a Block Inspector interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some interview tips and hacks to help you ace the interview:

1. Research the Company and the Industry

Before the interview, take the time to research the company and the concrete block industry. This will give you a good understanding of the company’s values, mission, and products. You should also be familiar with the latest trends and developments in the industry.

- Visit the company’s website

- Read industry publications

- Attend industry events

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in Block Inspector interviews. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about your experience in the concrete block industry.

- What are your strengths and weaknesses as a Block Inspector?

- Why are you interested in this position?

3. Be Prepared to Talk About Your Experience

In addition to practicing your answers to common interview questions, you should also be prepared to talk about your experience in the concrete block industry. This includes your experience in inspecting and testing concrete blocks, as well as your experience in monitoring the production process.

- Highlight your skills and experience

- Use specific examples to illustrate your abilities

- Quantify your results whenever possible

4. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional during the interview. Dress appropriately, arrive on time, and make eye contact with the interviewer. Be polite and respectful, and answer questions honestly and confidently.

- Smile and make eye contact

- Be polite and respectful

- Answer questions honestly and confidently

Next Step:

Now that you’re armed with the knowledge of Block Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Block Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini