Are you gearing up for an interview for a Bobbin Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bobbin Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

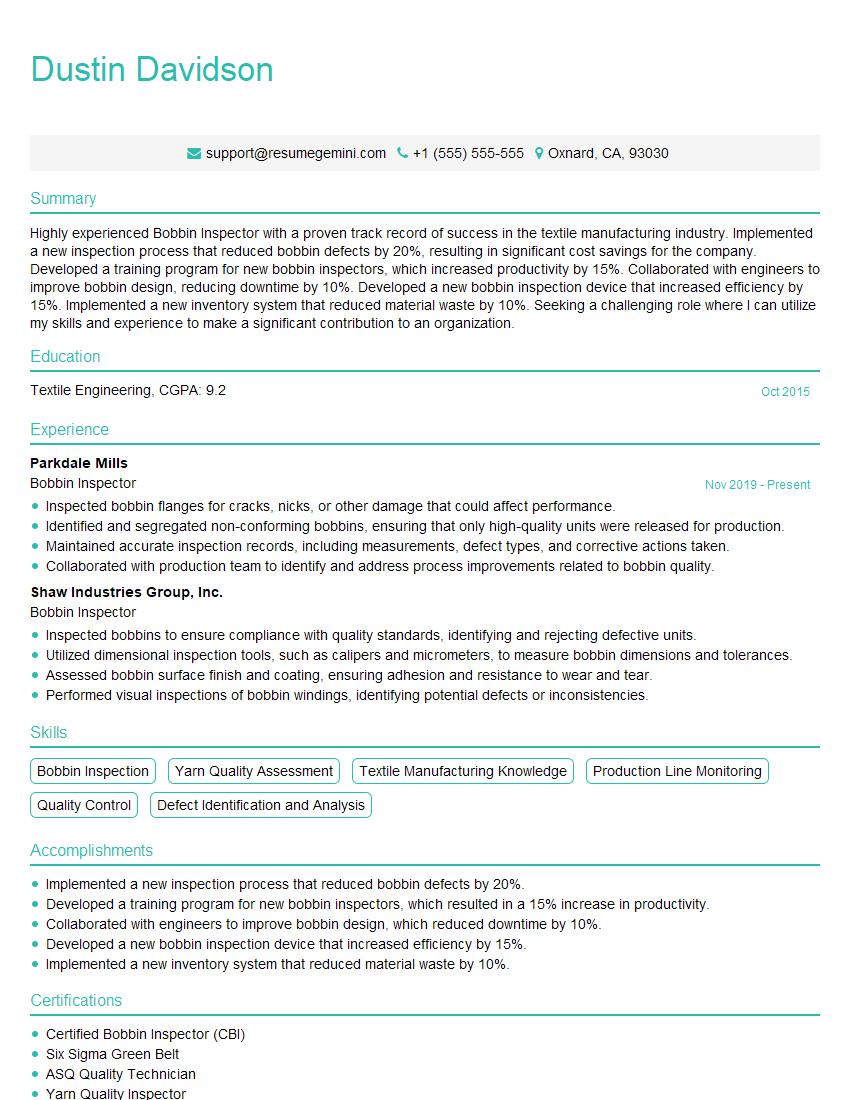

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bobbin Inspector

1. What are the key factors to consider when assessing the quality of a yarn bobbin?

When assessing the quality of a yarn bobbin, I typically consider the following factors:

- Condition of the yarn: This includes checking for any knots, breaks, or other defects that could affect the quality of the yarn.

- Dimensions of the bobbin: The bobbin should be the correct size and shape for the machine it will be used on.

- Tension of the yarn: The yarn should be wound onto the bobbin with the correct tension to prevent it from slipping or breaking during use.

- Appearance of the bobbin: The bobbin should be free of any dirt, dust, or other contaminants that could affect the quality of the yarn.

2. How do you ensure that bobbins meet the required specifications?

Quality Control Measures

- Visual inspection: I visually inspect each bobbin to check for any defects.

- Dimensional measurement: I measure the dimensions of each bobbin to ensure that it meets the required specifications.

- Tension testing: I test the tension of the yarn on each bobbin to ensure that it is within the required range.

- Appearance inspection: I inspect the appearance of each bobbin to ensure that it is free of any contaminants.

Corrective Actions

- Rejecting defective bobbins: I reject any bobbins that do not meet the required specifications.

- Adjusting winding parameters: If a batch of bobbins is consistently failing to meet specifications, I adjust the winding parameters to correct the issue.

- Retraining operators: If bobbins are repeatedly being rejected due to operator error, I retrain the operators to ensure that they are following the correct procedures.

3. What are the different types of bobbin defects you have encountered in the past?

- Yarn defects: Knots, breaks, slubs, and other yarn defects can affect the quality of the bobbin.

- Bobbin defects: Dents, scratches, or other defects on the bobbin can damage the yarn.

- Winding defects: Yarn that is wound too tightly or too loosely can cause problems during use.

- Contamination: Dirt, dust, or other contaminants can affect the quality of the yarn.

4. How do you handle bobbins that do not meet the required specifications?

- Identify and quarantine defective bobbins: I visually inspect each bobbin and set aside any bobbins that do not meet the required specifications.

- Document and report defects: I document the type and quantity of defects found on each bobbin in a quality control report.

- Initiate corrective actions: I work with the production team to identify and correct the root cause of the defects.

- Dispose of defective bobbins: Once the cause of the defects has been corrected, I dispose of the defective bobbins in accordance with company policy.

5. What are the key maintenance tasks involved in ensuring the proper functioning of bobbin winding machines?

- Regular cleaning and lubrication: Keeping the machine clean and well-lubricated helps to prevent breakdowns and extend the life of the machine.

- Tension adjustments: The tension of the yarn must be adjusted regularly to ensure that the bobbins are wound correctly.

- Bobbin inspection: I visually inspect the bobbins to check for any defects that could affect the quality of the yarn.

- Calibration: The machine should be calibrated regularly to ensure that it is measuring and winding the yarn accurately.

6. How do you troubleshoot common problems with bobbin winding machines?

- Yarn breakage: Yarn breakage can be caused by a variety of factors, including incorrect tension, damaged yarn, or a problem with the winding machine.

- Bobbin wobble: Bobbin wobble can be caused by an unbalanced bobbin, a worn bearing, or a problem with the winding machine.

- Uneven winding: Uneven winding can be caused by incorrect tension, a damaged winding head, or a problem with the winding machine.

- Machine vibration: Machine vibration can be caused by a loose belt, a worn bearing, or a problem with the motor.

7. What are your quality control procedures for bobbin winding?

- Visual inspection: I visually inspect each bobbin to check for any defects.

- Dimensional measurement: I measure the dimensions of each bobbin to ensure that it meets the required specifications.

- Tension testing: I test the tension of the yarn on each bobbin to ensure that it is within the required range.

- Appearance inspection: I inspect the appearance of each bobbin to ensure that it is free of any contaminants.

8. How do you manage your time and prioritize your work when you are under pressure?

- Prioritize tasks: I prioritize my tasks based on their importance and urgency.

- Create a schedule: I create a schedule and stick to it as much as possible.

- Delegate tasks: I delegate tasks to other team members when appropriate.

- Stay organized: I keep my work area organized and my files up-to-date.

- Take breaks: I take breaks throughout the day to clear my head and come back refreshed.

9. What are your strengths and weaknesses as a Bobbin Inspector?

Strengths

- Attention to detail: I am able to identify and correct even the smallest defects in bobbins.

- Quality-oriented: I am committed to producing high-quality bobbins that meet the required specifications.

- Problem-solving skills: I am able to quickly identify and resolve problems with bobbin winding machines.

- Team player: I am able to work effectively as part of a team to achieve common goals.

Weaknesses

- Speed: I am not the fastest bobbin inspector, but I am always accurate.

- Repetitive work: I can sometimes find the work of a bobbin inspector to be repetitive, but I always maintain my focus on quality.

10. Why are you interested in this position?

- Your company’s reputation: I am impressed by your company’s reputation for producing high-quality products.

- The opportunity to learn and grow: I am eager to learn more about the bobbin winding process and to contribute to your company’s success.

- The chance to make a difference: I believe that my skills and experience as a Bobbin Inspector can help your company to produce even better products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bobbin Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bobbin Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Bobbin Inspector

Bobbin inspectors play a critical role in ensuring the quality of textiles by inspecting and evaluating bobbins used in the manufacturing process.

1. Bobbin Inspection

Thoroughly inspect bobbins for defects, such as cracks, chips, or other damage.

- Identify and remove defective bobbins to prevent production issues.

- Use specialized equipment, such as microscopes or optical comparators, for precise inspections.

2. Quality Control

Monitor production processes to ensure that bobbins meet established quality standards.

- Measure and record bobbin dimensions, such as length, diameter, and flange thickness.

- Inspect bobbins for surface finish, color, and any other specified criteria.

3. Data Collection and Reporting

Collect and record inspection data, including the number of bobbins inspected, defects found, and corrective actions taken.

- Prepare and submit inspection reports to supervisors and quality control personnel.

- Participate in quality improvement initiatives by identifying and recommending process enhancements.

4. Equipment Maintenance

Perform basic maintenance on inspection equipment to ensure accuracy and efficiency.

- Clean and calibrate equipment according to manufacturer’s specifications.

- Report any equipment malfunctions or repairs needed to supervisors promptly.

Interview Tips for Bobbin Inspector Position

To ace your Bobbin Inspector interview, follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry. Research the specific job requirements and responsibilities.

- Visit the company’s website, read industry publications, and connect with current or former employees.

- Tailor your resume and cover letter to highlight skills and experience relevant to the position.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. Focus on demonstrating your inspection skills, attention to detail, and commitment to quality control.

- Examples: “Can you describe your experience in bobbin inspection?”

- “How do you ensure that bobbins meet quality standards?”

3. Emphasize Your Attention to Detail

Bobbin inspectors must have a keen eye for detail. Highlight your ability to identify and assess defects, even minor ones.

- Provide examples of how you have used your attention to detail to improve quality or prevent errors.

- Explain how you stay focused and maintain accuracy during repetitive tasks.

4. Showcase Your Technical Skills

Discuss your proficiency in using inspection equipment, such as microscopes or optical comparators. Explain how you ensure the equipment is properly calibrated and maintained.

- If possible, bring examples or certifications that demonstrate your technical abilities.

- Be prepared to explain how you troubleshoot and resolve equipment issues.

5. Be Enthusiastic and Professional

Show the interviewer that you are genuinely passionate about quality control and eager to contribute to the company’s success.

- Dress professionally and arrive on time for your interview.

- Ask thoughtful questions to show your interest and understanding of the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bobbin Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.