Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Calibration Checker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

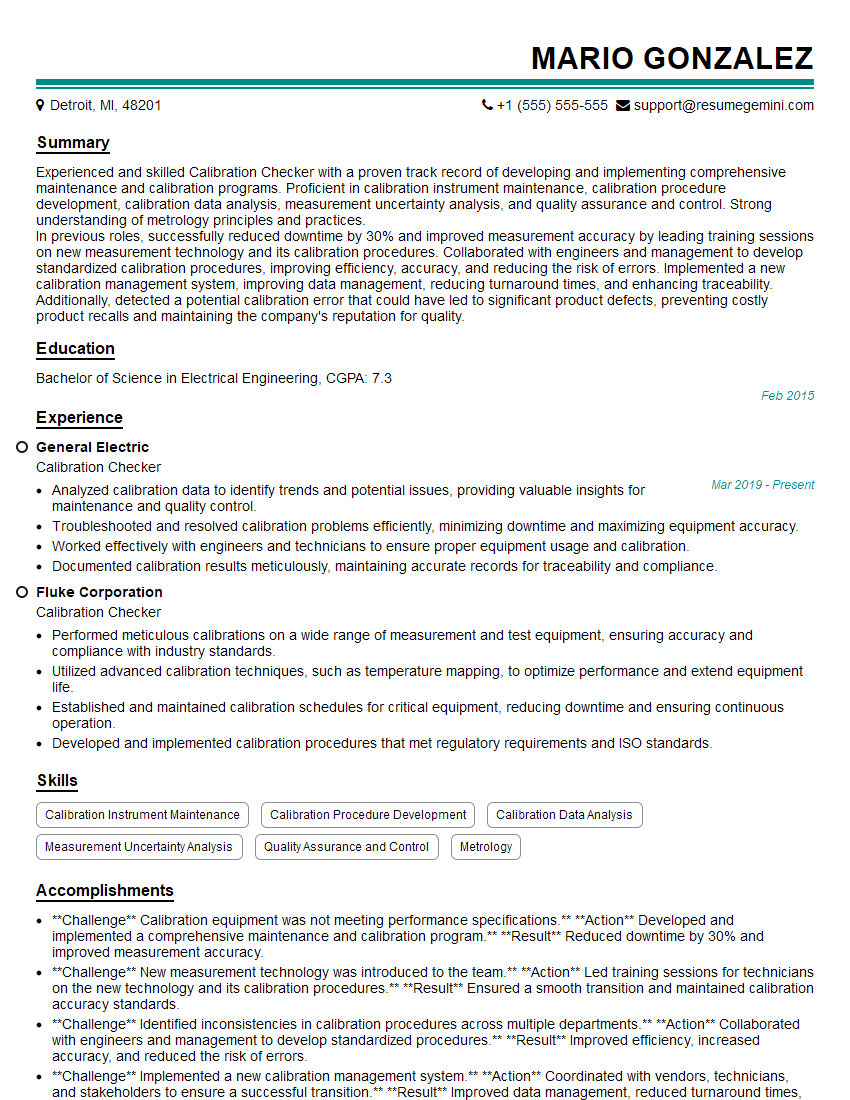

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calibration Checker

1. What are the different types of calibration checks and when would you use each type?

There are three main types of calibration checks: functional check, calibration verification check, and full calibration.

- Functional Checks are used to verify that the instrument is working properly. They involve using a known good input and comparing the output to a known acceptable range. Functional checks are typically done before each use of the instrument.

- Calibration Verification Checks are used to verify that the instrument is still within its calibration tolerance. They involve using a known good input and comparing the output to a known acceptable range. Calibration verification checks are typically done periodically, such as monthly or quarterly.

- Full Calibrations are used to adjust the instrument to bring it back within its calibration tolerance. They involve using a series of known good inputs and comparing the outputs to known acceptable ranges. Full calibrations are typically done annually or when the instrument is suspected to be out of calibration.

2. What are the key steps involved in performing a calibration verification check?

- Identify the instrument to be checked.

- Gather the necessary equipment, including a known good input and a calibration verification procedure.

- Follow the calibration verification procedure to perform the check.

- Compare the output to the known acceptable range.

- Document the results of the calibration verification check.

3. What are the most common sources of error in calibration checks?

- Using an incorrect calibration standard

- Not following the calibration procedure correctly

- Environmental factors, such as temperature or humidity

- Instrument malfunction

4. What are the consequences of not performing calibration checks?

- Inaccurate measurements

- Product defects

- Safety hazards

- Regulatory non-compliance

5. What are the benefits of using a calibration management system?

- Improved accuracy and reliability of measurements

- Reduced downtime and maintenance costs

- Increased compliance with regulatory requirements

- Improved efficiency and productivity

6. What are the key features of a good calibration management system?

- Easy to use and navigate

- Comprehensive coverage of calibration activities

- Automated reminders and notifications

- Reporting and analysis capabilities

7. What are the different types of calibration standards?

- Primary standards are the highest level of calibration standards traceable to a national or international standard.

- Secondary standards are calibrated against primary standards and are used to calibrate other instruments.

- Working standards are used to calibrate instruments in the field.

8. What is the difference between calibration and adjustment?

9. What are the different types of calibration methods?

- Static calibration is performed using a known good input and comparing the output to a known acceptable range.

- Dynamic calibration is performed using a known good input and comparing the output to a known acceptable range while the instrument is in operation.

- As-found calibration is performed on an instrument before it has been adjusted.

- As-left calibration is performed on an instrument after it has been adjusted.

10. What are the different types of calibration documentation?

- Calibration certificates are issued by calibration laboratories and provide evidence that an instrument has been calibrated to a specific standard.

- Calibration reports are generated by calibration technicians and provide detailed information about the calibration process and results.

- Calibration records are maintained by users and provide a history of calibration activities for an instrument.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calibration Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calibration Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Calibration Checkers play a vital role in ensuring the accuracy and reliability of measuring equipment used in various industries.

1. Equipment Calibration and Verification

The primary responsibility is to calibrate and verify measuring instruments and equipment against established standards or specifications.

- Perform routine calibration and verification procedures on various devices, such as pressure gauges, thermometers, scales, flow meters, and analytical instruments.

- Use precision equipment and follow documented procedures to ensure accuracy and precision.

2. Quality Control

Calibration Checkers contribute to quality control by ensuring the reliability of measurements.

- Monitor and maintain the performance of calibration equipment and processes.

- Identify any deviations, errors, or discrepancies in calibration results.

- Implement corrective actions to maintain the accuracy and traceability of measurements.

3. Recordkeeping and Documentation

Accurate recordkeeping is crucial for maintaining compliance and ensuring the validity of calibration data.

- Maintain comprehensive records of all calibration activities, including procedures, results, and adjustments.

- Generate calibration certificates and reports to provide evidence of equipment performance.

- Adhere to applicable industry standards and regulations related to calibration and documentation.

4. Training and Development

Calibration Checkers may be responsible for training and mentoring other personnel involved in calibration activities.

- Provide training on calibration procedures, equipment, and quality control measures.

- Stay up-to-date with industry best practices and advancements in calibration techniques.

Interview Tips

To ace the interview for a Calibration Checker position, it’s essential to prepare thoroughly and demonstrate your skills and knowledge.

1. Research the Company and Industry

Research the organization you’re applying to and the industry it operates in. Understanding their products, services, and quality standards will help you tailor your answers to the specific requirements of the role.

- Visit the company website and social media pages.

- Read industry-related articles and publications.

2. Highlight Your Technical Skills

Emphasize your technical proficiency in calibration techniques and equipment. Quantify your experience and provide specific examples of projects or tasks you’ve successfully completed.

- Discuss your knowledge of different calibration methods, such as static, dynamic, and comparative.

- Showcase your ability to troubleshoot calibration issues and implement corrective actions.

3. Demonstrate Your Attention to Detail and Accuracy

Accuracy and attention to detail are crucial qualities for a Calibration Checker. Highlight examples where you’ve maintained meticulous records, ensured precision in measurements, and identified and corrected errors.

- Describe a situation where you identified a discrepancy in calibration data and implemented a corrective action.

- Explain your process for maintaining and calibrating your own equipment to ensure accuracy and reliability.

4. Emphasize Your Quality Control Mindset

Demonstrate your commitment to quality control and adherence to industry standards. Explain how you ensure the validity and traceability of calibration data and maintain the performance of calibration equipment.

- Describe your experience in implementing quality control measures in a calibration laboratory.

- Highlight your knowledge of relevant industry standards, such as ISO 17025 or ANSI/NCSL Z540.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Calibration Checker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Calibration Checker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.