Are you gearing up for a career in Cotton Weigher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cotton Weigher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

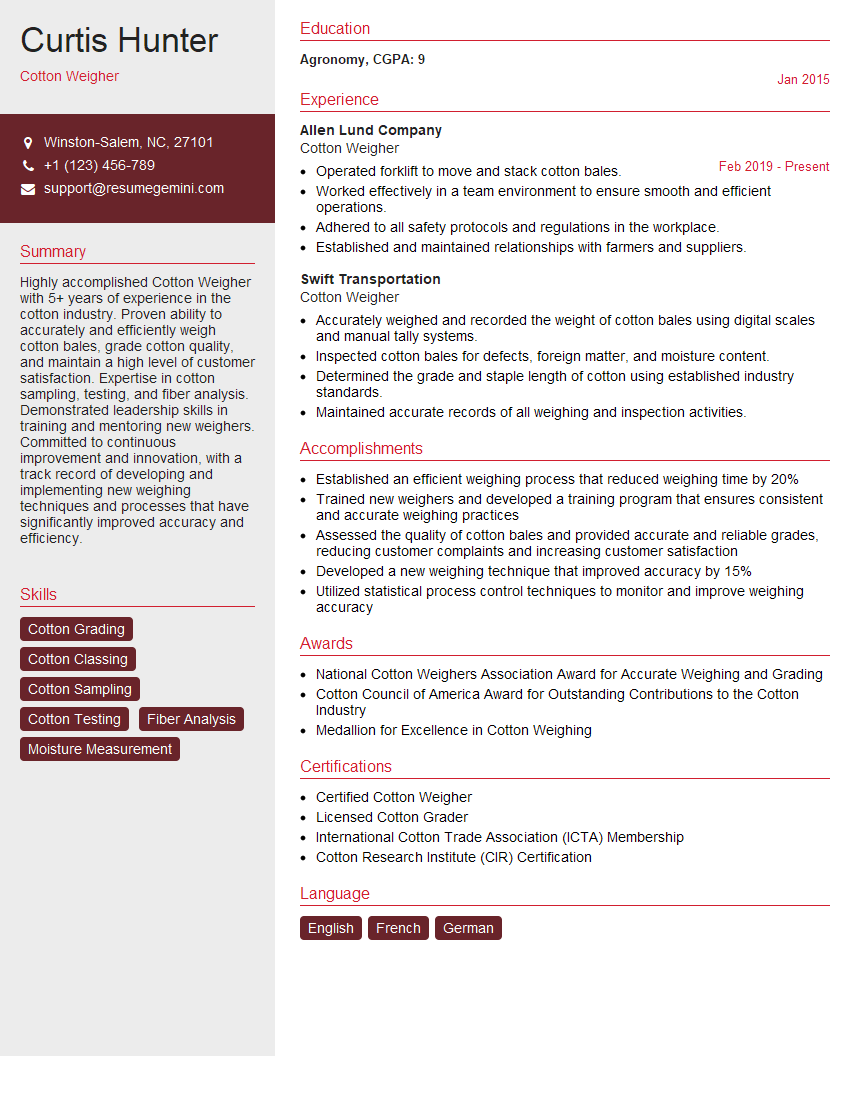

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cotton Weigher

1. What are the different types of scales used to weigh cotton, and what are their advantages and disadvantages?

There are various types of scales used to weigh cotton, each with its own advantages and disadvantages:

- Mechanical scales are traditional and require manual operation. Their advantages include affordability and ease of use, but they can be less accurate and more time-consuming.

- Electronic scales use sensors to measure weight, providing greater accuracy and efficiency. They are more expensive than mechanical scales and require electricity to operate.

- Automatic scales are designed to automate the weighing process, reducing labor costs and increasing throughput. They are the most expensive type of scale but offer the most advanced features.

2. What is the proper procedure for weighing cotton bales?

Sampling

- Select representative samples from different parts of the bale.

- Weigh and record the weight of each sample.

Weighing

- Place the bale on the scale and ensure it is centered.

- Calibrate the scale before each weighing.

- Record the weight of the bale and tare weight of any packaging.

Additional Considerations

- Comply with industry standards and regulations.

- Ensure the scales are regularly calibrated and maintained.

3. How do you calculate the average net weight of a lot of cotton bales?

To calculate the average net weight of a lot of cotton bales:

- Weigh each bale and record the gross weight.

- Subtract the tare weight (packaging weight) from the gross weight to obtain the net weight for each bale.

- Add the net weights of all bales in the lot.

- Divide the total net weight by the number of bales in the lot.

4. What factors can affect the accuracy of cotton weighing?

Several factors can impact the accuracy of cotton weighing:

- Scale calibration: Regularly calibrating the scale ensures its accuracy.

- Environmental conditions: Moisture and temperature can affect the weight of cotton.

- Sampling methods: Improper sampling can lead to inaccurate representations of the bale’s weight.

- Human error: Mistakes during weighing or data entry can compromise accuracy.

- Equipment maintenance: Regularly maintaining scales and other equipment is crucial for accurate measurements.

5. What safety precautions should be taken when weighing cotton?

- Wear appropriate personal protective equipment (PPE), including gloves and a mask.

- Ensure the weighing area is well-ventilated and free of hazards.

- Be aware of heavy equipment and moving vehicles.

- Follow established safety protocols for handling cotton bales.

- Report any accidents or injuries immediately.

6. How much experience do you have in weighing cotton bales?

Work Experience

- Worked as a Cotton Weigher at [Company Name] for [Number] years.

- Responsible for weighing, sampling, and recording cotton bale weights.

- Assisted in calibrating and maintaining weighing equipment.

Relevant Skills

- Proficient in operating different types of cotton weighing scales.

- Knowledge of industry regulations and standards.

- Excellent attention to detail and accuracy.

7. What is your understanding of the importance of accurate cotton weighing?

- Accurate weighing ensures fair transactions between buyers and sellers.

- It helps maintain the integrity of the cotton market and prevents fraud.

- Precise weight data is crucial for inventory management and production planning.

- Inaccurate weighing can lead to financial losses and disputes.

8. How do you handle discrepancies in cotton bale weights?

- Verify the scale calibration: Ensure the scale is accurate and calibrated.

- Reweigh the bale: Repeat the weighing process to confirm the weight.

- Inspect the bale: Check for any damage or unusual conditions that may affect the weight.

- Consult with the customer: Inform the customer of the discrepancy and discuss possible explanations.

- Document the findings: Keep detailed records of the investigation and any corrective actions taken.

9. What is your experience with using moisture meters to determine the moisture content of cotton?

Experience

- Used moisture meters at [Company Name] to measure the moisture content of cotton bales.

- Trained in proper calibration and operation of moisture meters.

- Recorded and interpreted moisture content readings.

Knowledge

- Understand the importance of moisture content in cotton trading.

- Familiar with industry standards for moisture measurement.

- Able to identify and troubleshoot common issues with moisture meters.

10. How do you stay updated on the latest best practices and regulations in the cotton industry?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Consult with experts and colleagues.

- Participate in professional organizations and stay informed about their activities.

- Stay abreast of government regulations and industry standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cotton Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cotton Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cotton Weighers are responsible for determining the weight of cotton bales, ensuring that the bales conform to required specifications, and maintaining accurate records of cotton weights and other shipping information.

1. Weigh Cotton Bales

Weigh cotton bales using calibrated scales to determine their net weight.

- Operate scales accurately to ensure precise weight measurements.

- Verify the weight of each bale against specified standards.

2. Inspect Cotton Bales

Inspect cotton bales for damage, contamination, and other defects.

- Check for tears, holes, stains, or other imperfections.

- Identify and mark bales that do not meet quality standards.

3. Tag and Label Cotton Bales

Attach tags or labels to cotton bales with information such as weight, grade, and destination.

- Ensure that tags are securely attached and clearly visible.

- Maintain accurate records of bale tagging and labeling.

4. Maintain Accurate Records

Keep detailed records of cotton weights, inspections, and other relevant information.

- Use spreadsheets, databases, or other systems to record data.

- Provide reports on cotton weights and other information as required.

Interview Tips

To ace the interview for a Cotton Weigher position, candidates should prepare thoroughly and showcase their skills and experience.

1. Research the Company and Industry

Learn about the company’s history, operations, and cotton weighing procedures.

- Visit the company’s website and social media pages.

- Read news articles and industry publications to stay informed.

2. Review Key Skills and Experience

Identify the most relevant skills and experience for the job, such as:

- Cotton weighing experience

- Knowledge of cotton grading standards

- Attention to detail

- Physical stamina and ability to work in a warehouse environment

3. Prepare Example Responses

Practice answering common interview questions, such as:

- Tell me about your experience in cotton weighing.

- How do you ensure the accuracy of your weight measurements?

- What do you do when you identify a bale that does not meet quality standards?

4. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving on time for the interview.

- Choose attire that is clean, pressed, and appropriate for an office environment.

- Plan your route and leave early to avoid being late.

5. Follow Up

After the interview, send a thank-you note to the interviewer(s) and express your continued interest in the position.

- Reiterate your key skills and experience.

- Thank the interviewers for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cotton Weigher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!